Category: Oil and Gas

Bohr Instrument Services

Veenoord, The Netherlands

Category: Oil and Gas

Veenoord, The Netherlands

“Extensive visualization of all the key parameters by the GENESIS software system helps the drilling operator to prevent problems, drill more efficiently and reduce drilling time, which translates into overall cost savings.”

Oil and gas producing companies in the world explore on both land and sea to produce oil. Global energy companies that explore for oil and gas produce and refine oil and market their products throughout the world under their corporate brand names, and many use Drill-Pro Systems by Bohr BV. On exploration sites worldwide, these oil companies have installed a Bohr “DRILL-PRO” System with GENESIS software to monitor and control all the operations of the drilling rig.

“Extensive visualization of all the key parameters by the GENESIS software system helps the drilling operator to prevent problems, drill more efficiently and reduce drilling time, which translates into overall cost savings.”

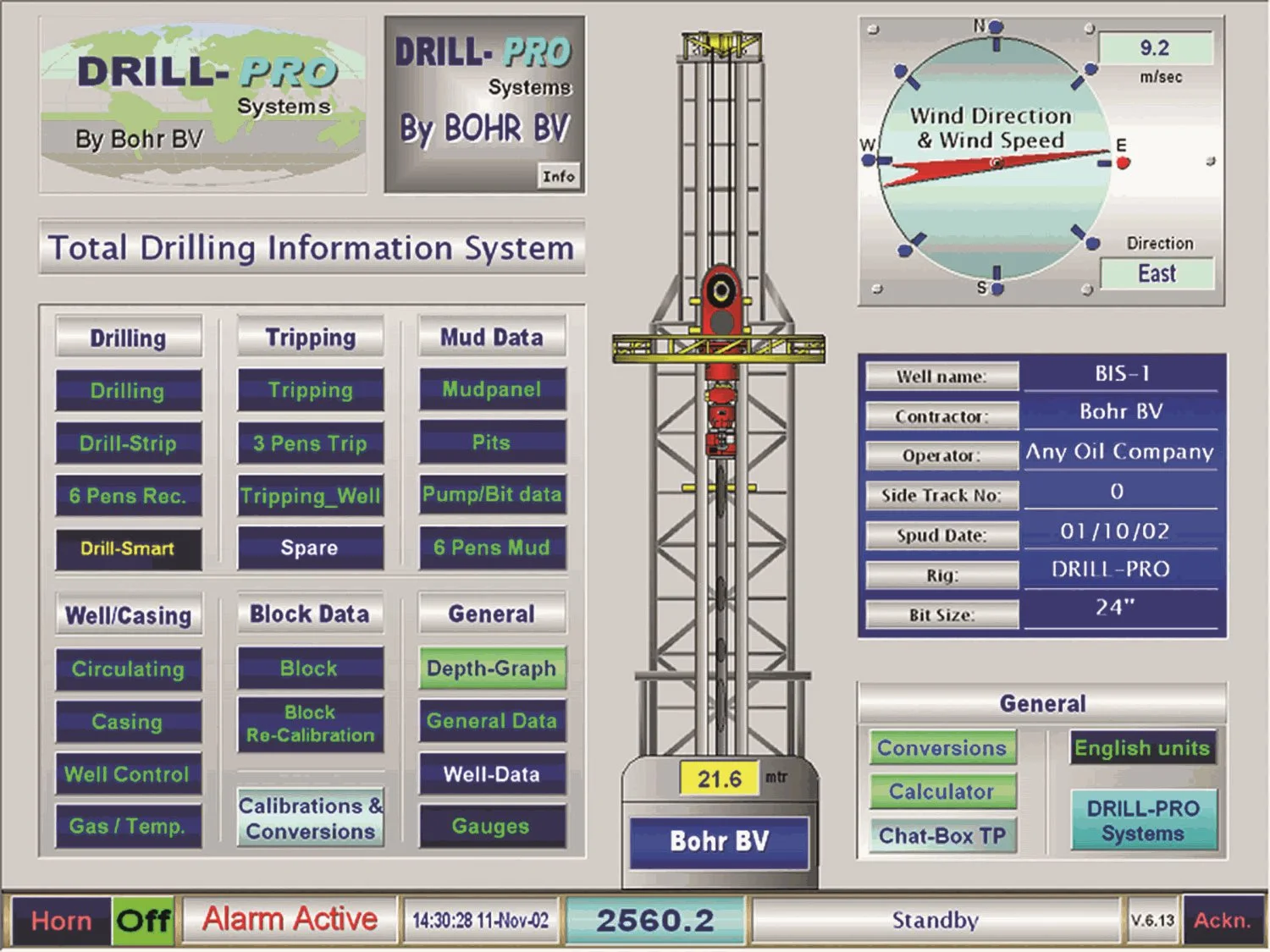

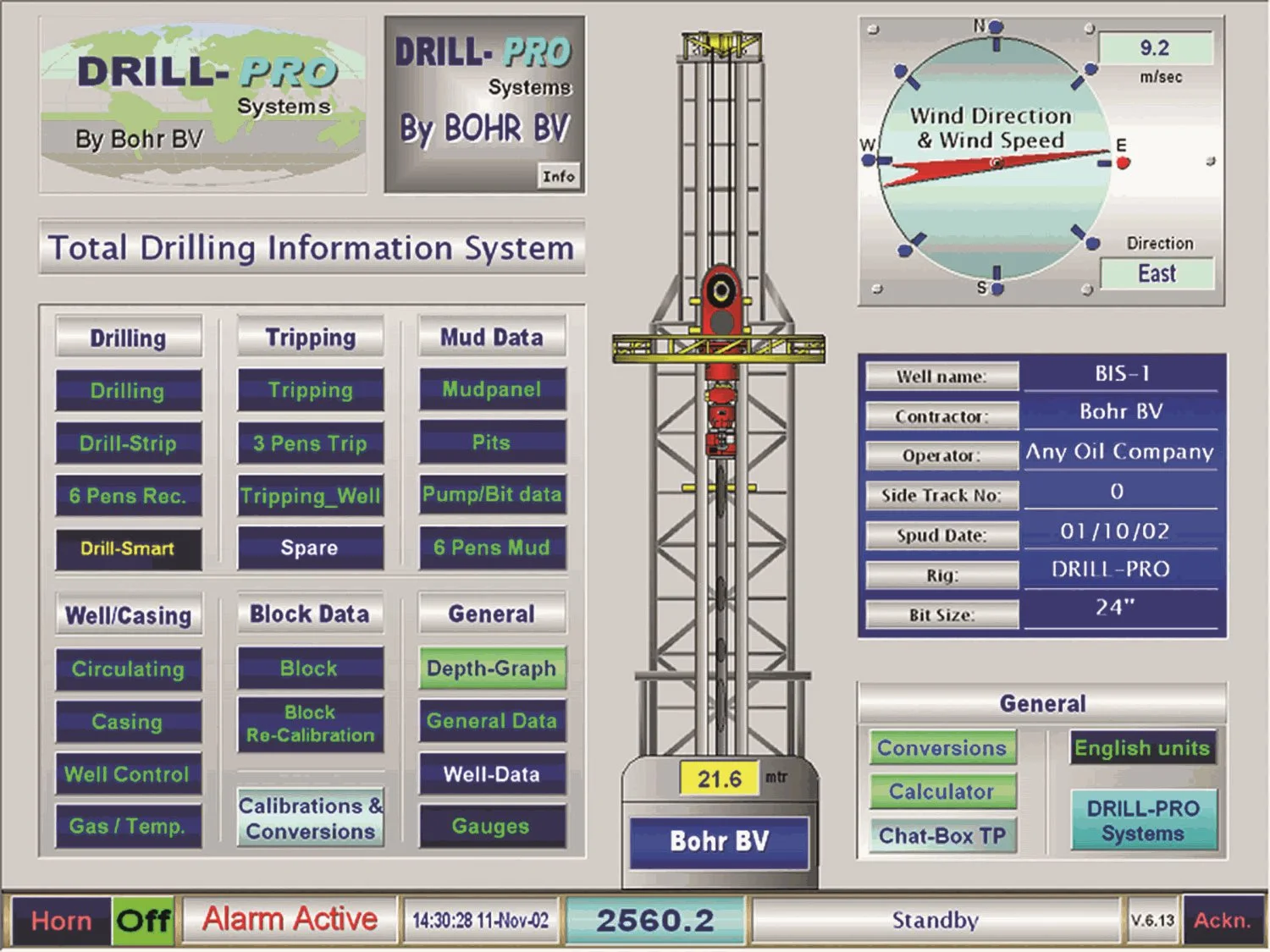

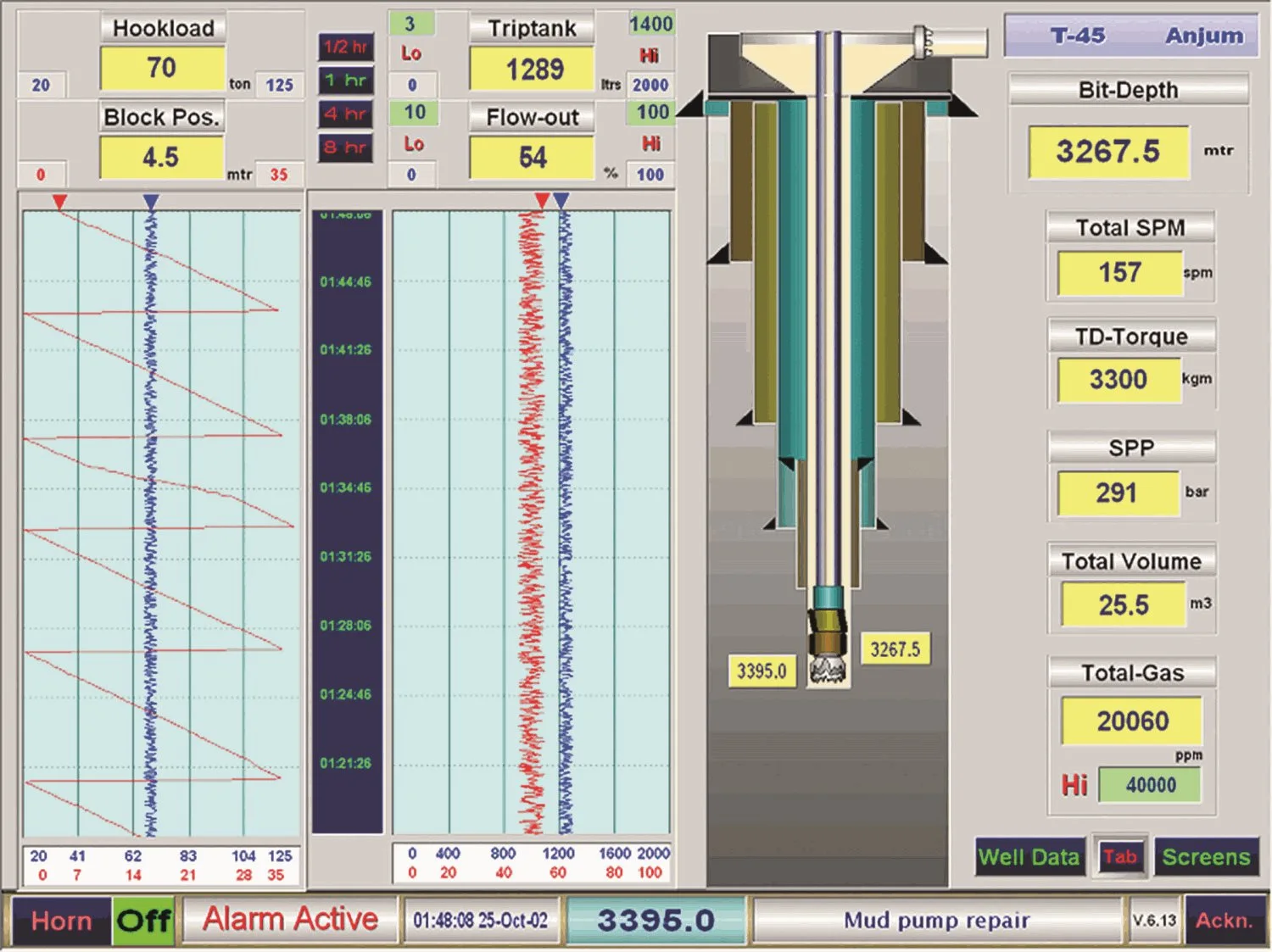

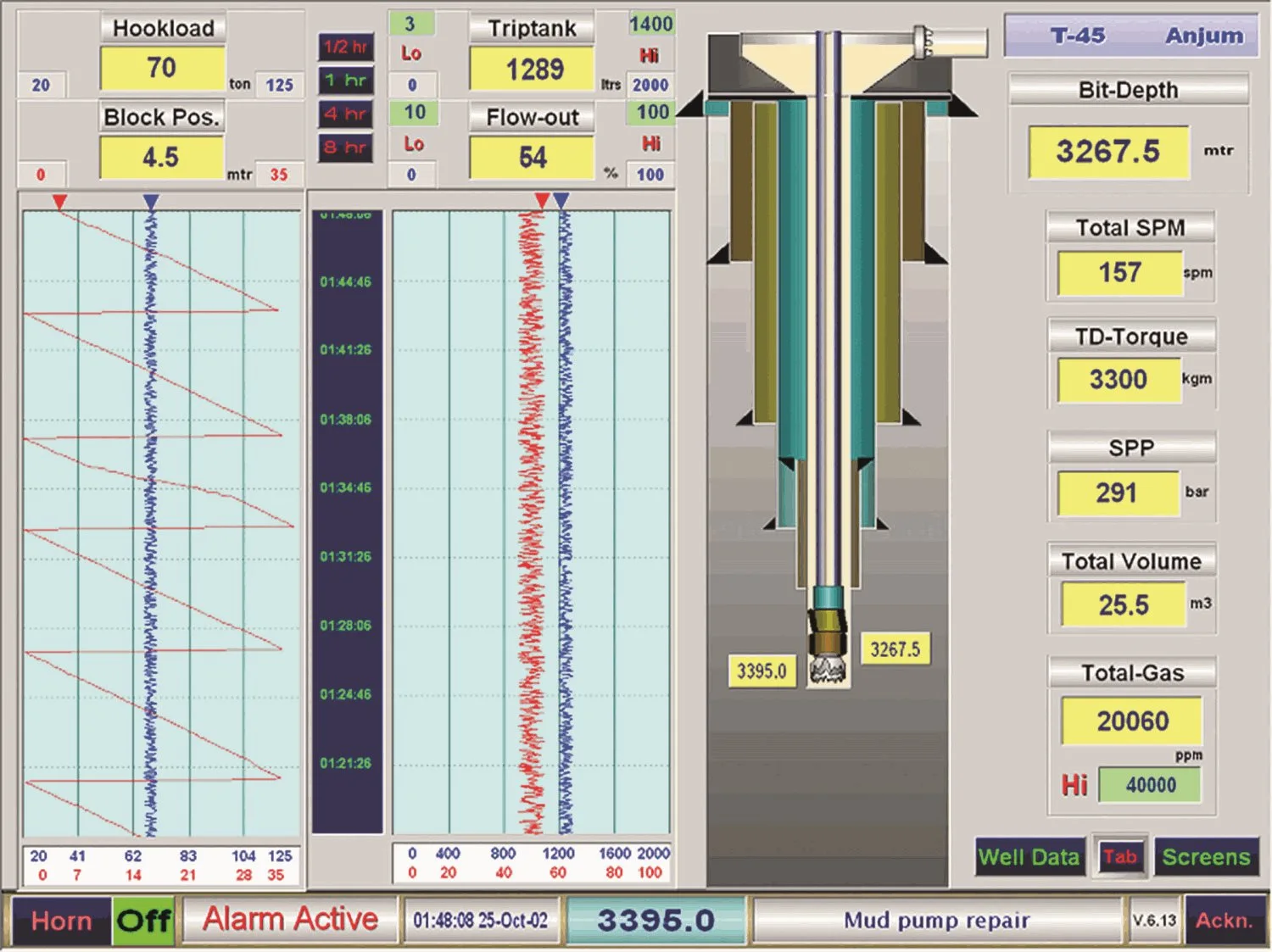

Bohr’s DRILL-PRO System Menu Display

Bohr’s DRILL-PRO System Menu Display

Bohr Instrument Services selected the GENESIS software suite with GraphWorX™, TrendWorX™ and AlarmWorX™. This suite of software tools is installed on a Bohr DRILL-PRO Total Drilling Information System, which is an extensive data acquisition system for oil and gas rigs.

This system must collect data in real time and monitors all the extreme forces on a drill bit while providing the drilling operator with multiple graphical data monitors that visualize all the collected data using the GENESIS software tools.

Bohr’s DRILL-PRO System Menu Display

Bohr’s DRILL-PRO System Menu Display

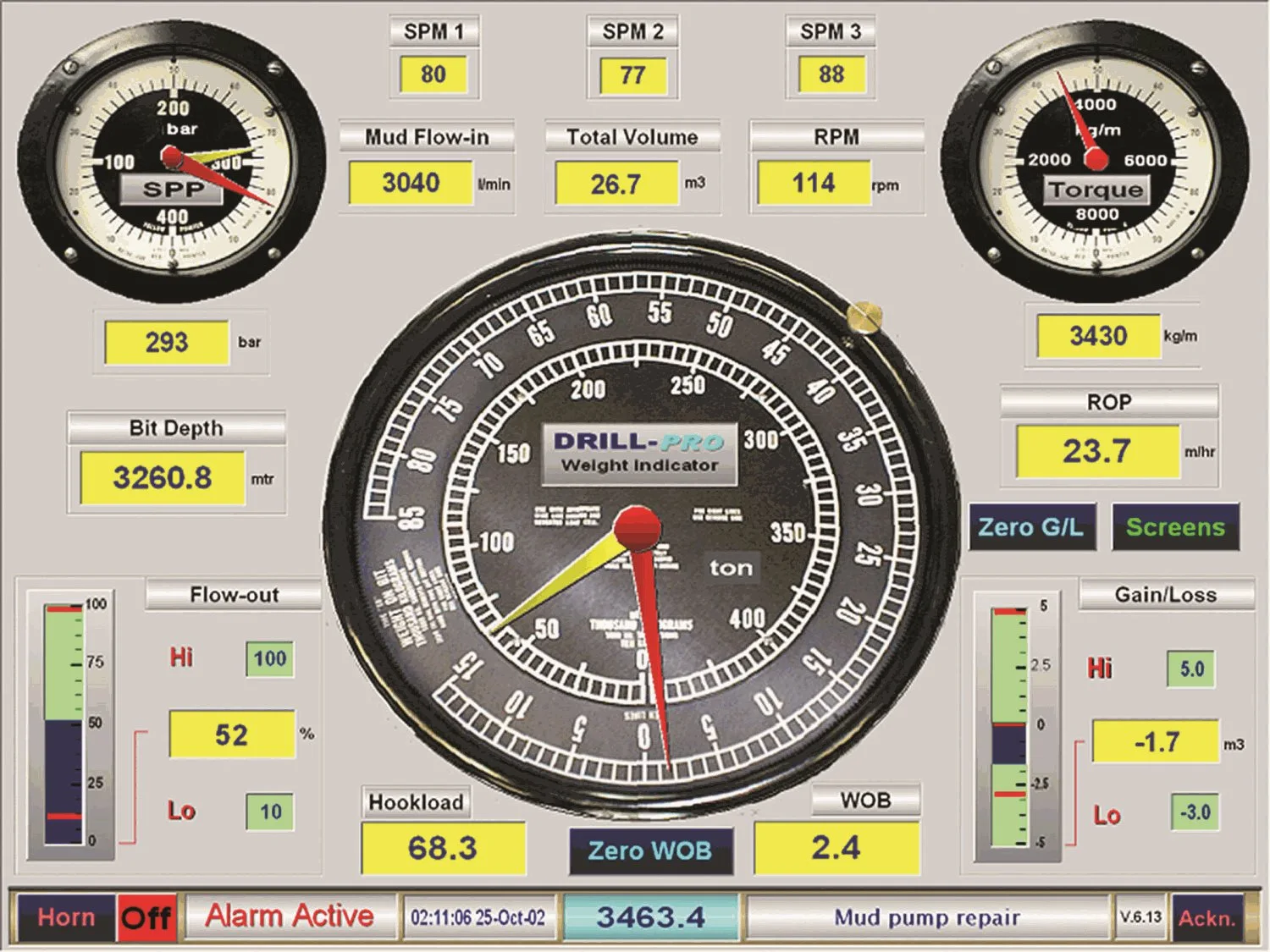

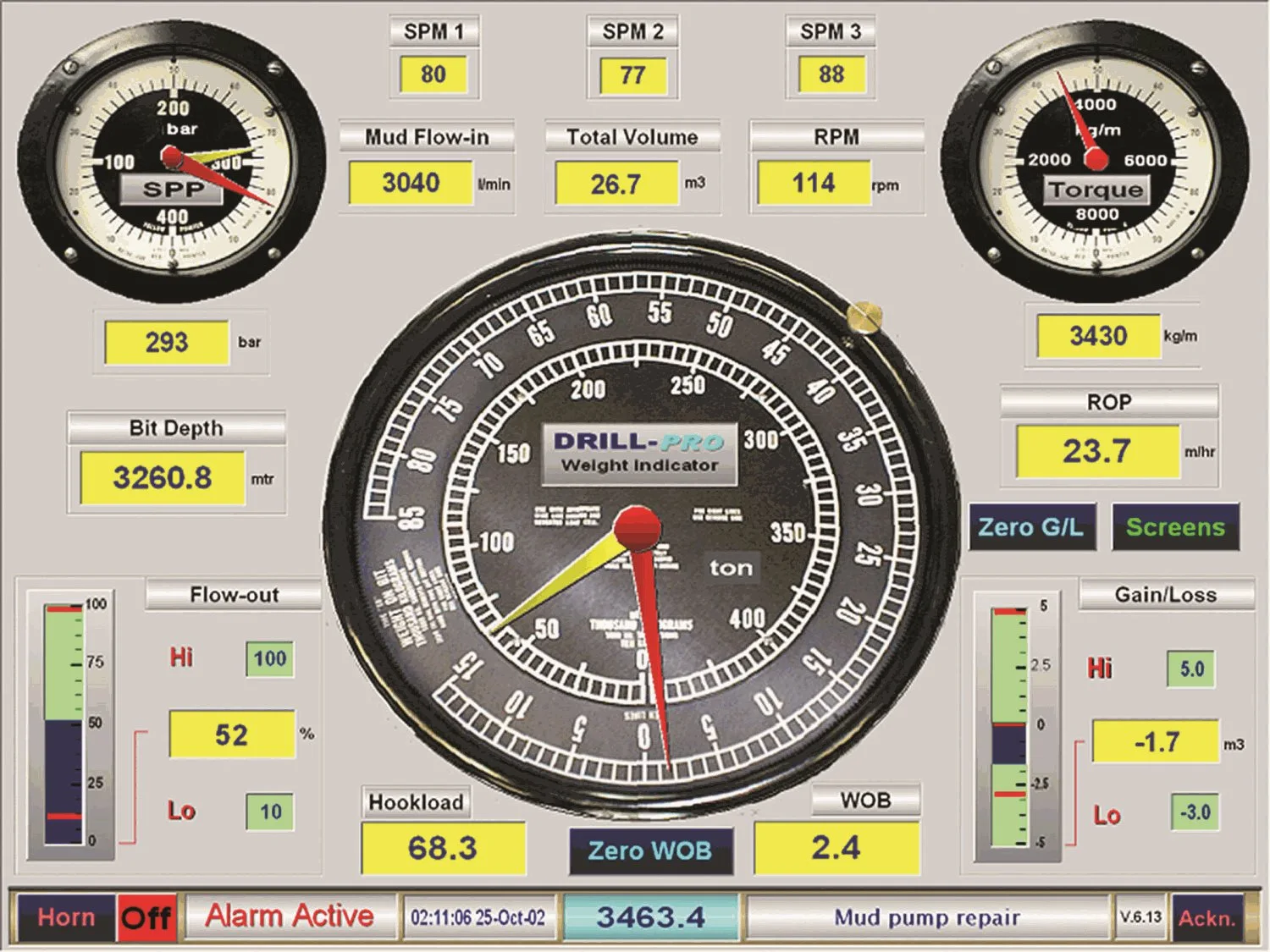

Virtual Gauges on Bohr DRILL-PRO display

Virtual Gauges on Bohr DRILL-PRO display

The DRILL-PRO package gathers data from digital and analog rig site sensors via a PLC data acquisition unit. It uses a direct RS-232 serial connection between the DRILL-PRO System, interfaced to a Modbus server and Nyquist PLC. The operator PC collects data and is transmitted to two locations; the drill floor, where an operator views the graphic representation of the data on an 18” monitor, and to remote offices. This drill floor HMI monitor communicates with the data acquisition module (DAQ) to pass on information concerning screen types, scales, alarm limits and manual entries by the operator (depth, bit depth, pump efficiency etc.).

The same real-time data is communicated wirelessly via an 802.11b network protocol to three separate computers in the engineering and project management offices. The many parameters that need to be logged and converted into other parameters demand a software system that can process an unlimited amount of real-time data from a variety of inputs. The system utilizes a distributed I/O architecture, saving costs and providing for flexible layouts and better reliability overall.

Virtual Gauges on Bohr DRILL-PRO display

Virtual Gauges on Bohr DRILL-PRO display

The DRILL-PRO monitoring system required an easy-to-use, user selectable graphical and alphanumeric display software system. The GENESIS software suite met these requirements, which included alarm monitoring of all the primary instrumentation. The installed system has the flexibility needed for customization and the modular structure of the software allows for easy configuration changes and upgrading. The DRILL-PRO system accepts signals from a large number of sensors (rotary RPM, depth, pump pressure, temperature and tank levels).

The values measured by these sensors are displayed in several graphical screens and used to calculate other important derived parameters like rate of penetration, weight on drill bit, hole volume, running time and pipe counts. This almost overwhelming amount of information is collected by the GENESIS software system and presented in several clear graphical displays. The operator selects which screen to view using a touch screen and can then set parameters and alarm conditions as required.

A DRILL-PRO Trip/Well Display Showing Vertical Trending by Bohr

A DRILL-PRO Trip/Well Display Showing Vertical Trending by Bohr

The primary benefit that GENESIS provides is the ability to do “vertical trending”. Data collected at the drill head and sent to the engineering and management offices’ computers are stored in triple redundancy in a Microsoft Access™ database. This data is “persistent trended” and stored in RAM memory for immediate access, along with “historical trended” data, which is stored on their hard drives for analysis.

Other advantages of the GENESIS software system are the ease of use, ease of setting up screens and the extensive visualization display capabilities for the operators to view real-time data.

A DRILL-PRO Trip/Well Display Showing Vertical Trending by Bohr

A DRILL-PRO Trip/Well Display Showing Vertical Trending by Bohr

Mitsubishi Electric Iconics Digital Solutions has worked closely and successfully with Bohr Instrument Services BV to make this Oil Rig Monitoring project successful in every aspect.