Category: Building Automation

Aristotle University of Thessaloniki

Thessaloniki, Greece

Category: Building Automation

Thessaloniki, Greece

“Within the first year of operating its new GENESIS software-integrated managed heating system, A.U.Th. cut 35.6 percent off its annual energy consumption compared to the previous year, translating to over 280,000 euros saved.”

The Aristotle University of Thessaloniki (A.U.Th.) is the largest university in Greece, covering 230,000 square meters in the center of the city of Thessaloniki. The school employs over 2,000 academic staff members, teaching over 40,000 students yearly. Established in 1925, the school was named after the well-known philosopher Aristotle and is a highly regarded educational institution in Greece.

“Within the first year of operating its new GENESIS software-integrated managed heating system, A.U.Th. cut 35.6 percent off its annual energy consumption compared to the previous year, translating to over 280,000 euros saved.”

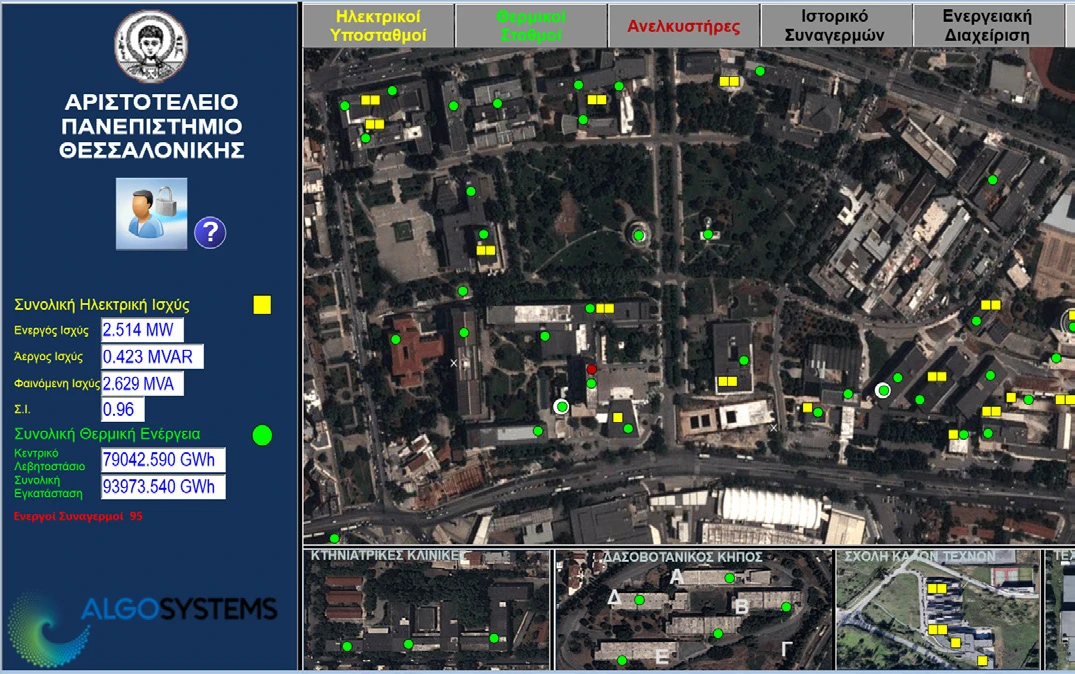

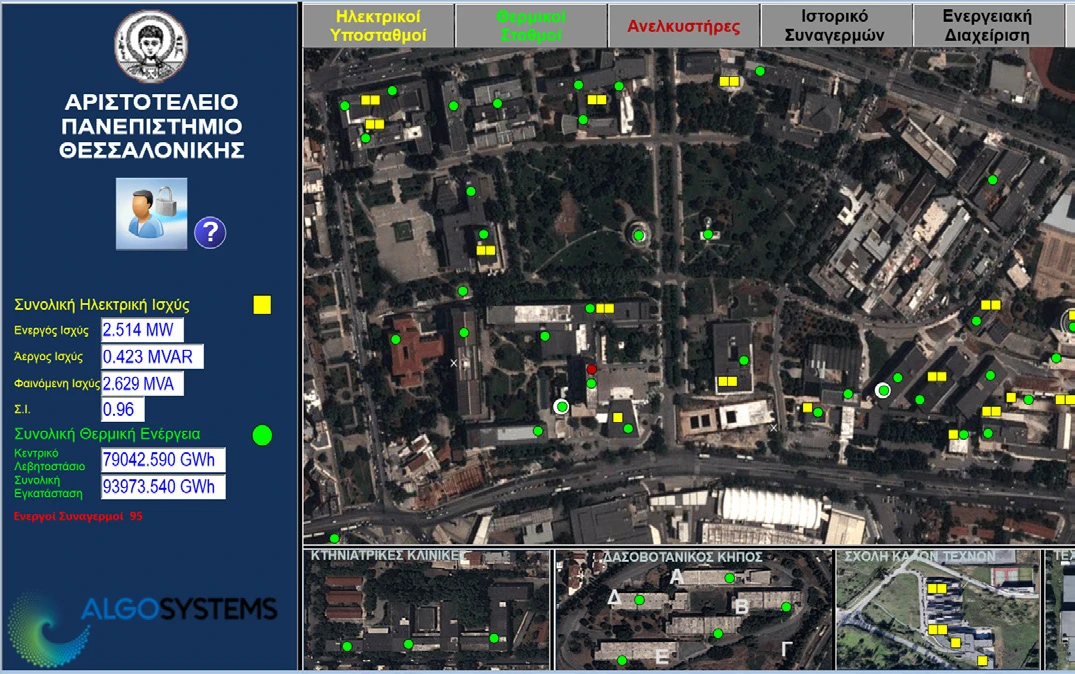

A.U.Th. Display Screen Created via GENESIS64

A.U.Th. Display Screen Created via GENESIS64

The Aristotle University of Thessaloniki, working with systems integrator Algosystems of Athens, Greece, selected Mitsubishi Electric Iconics Digital Solutions GENESIS64™ building automation and HMI/SCADA software suite.

A.U.Th. Display Screen Created via GENESIS64

A.U.Th. Display Screen Created via GENESIS64

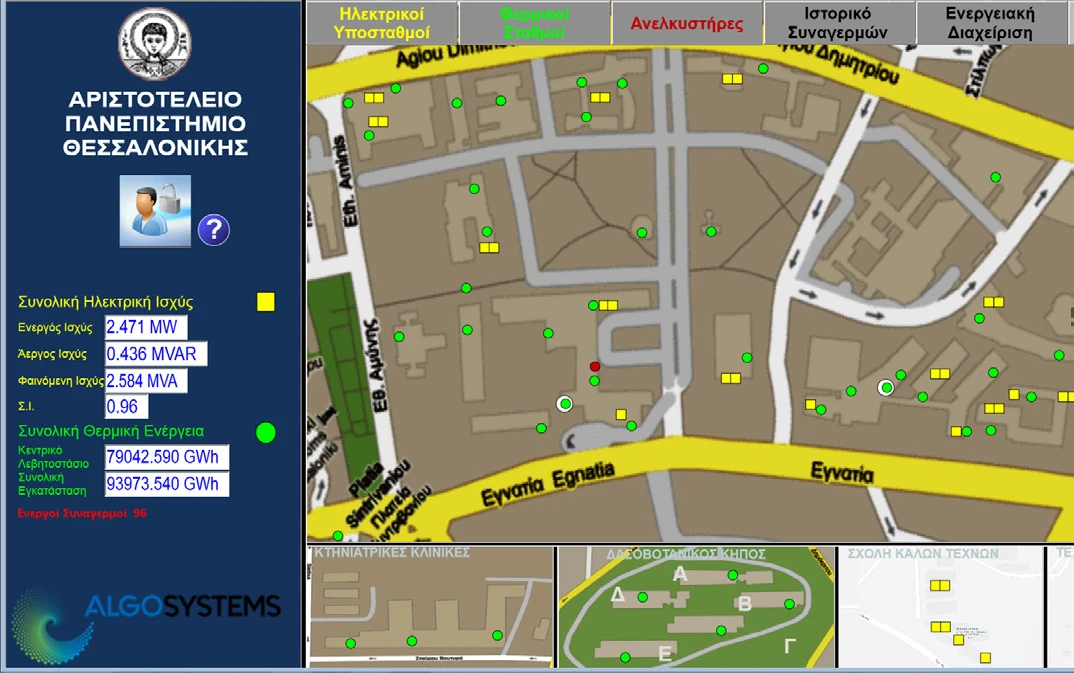

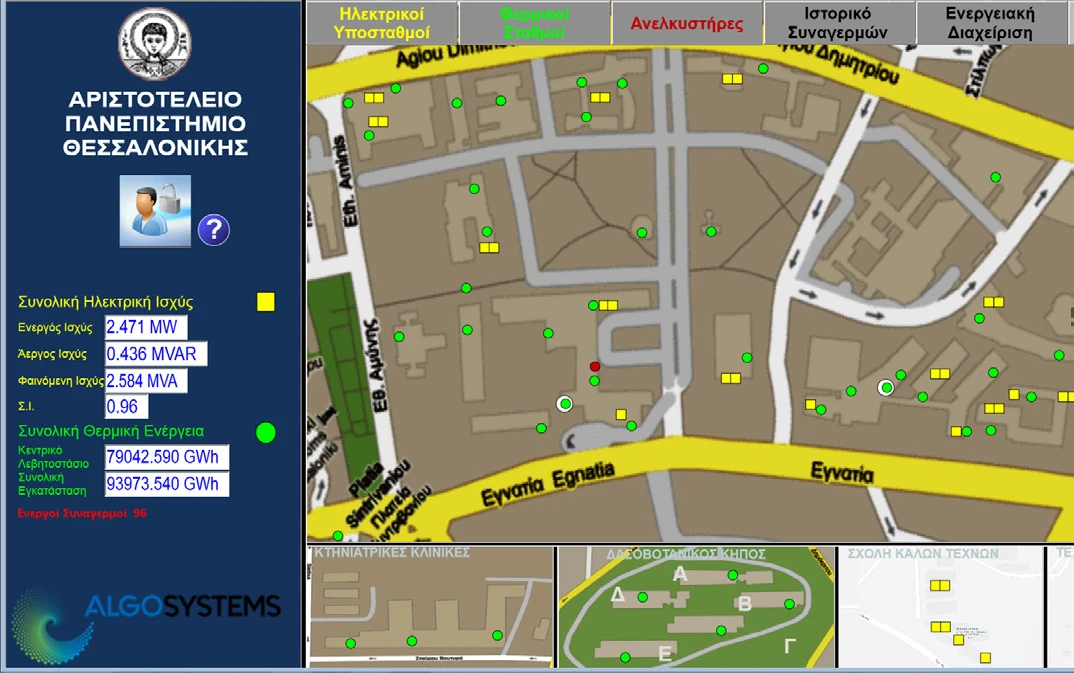

Alternate Campus Overview HMI/SCADA Display

Alternate Campus Overview HMI/SCADA Display

The buildings of the Aristotle University of Thessaloniki are located throughout five sites in the wide area of Thessaloniki. These include a central campus (334,000 square meters), a campus in Thermi (213,000 square meters), a university farm (1,885,706 square meters), the Forestry and Natural Environment department facilities, and the School of Veterinary Medicine clinics. Several additional sites are also overseen by the university, including additional buildings in Thessaloniki and several outside the city, including archaeological excavations in Vergina, Dion, and Pella, as well as university-owned forests.

Due to the wide dispersion of the buildings, their age, and old or nonexistent energy specifications at the time they were designed, energy consumption and the corre-sponding costs are very high. During the last six years,

the A.U.Th.’s energy policy was revised, with considerable efforts toward saving energy by renovating installations and buildings, adopting energy-saving policies, and radically modernizing energy control systems.

The heating of buildings in the A.U.Th. central campus is provided through a heating distribution network. Centrally located boilers on university grounds, including one in the Polytech School that handles about 90 percent of the total capacity of the central campus, connect to the steam network with corresponding exchangers within school build-ings. University facilities management, led by Professor Xenos Thomas of the School of Electrical and Computer Engineering, were tasked with reducing the fuel consumption related to this heating network. As part of these efforts, including infrastructure updates to both the boilers and the heating network, the A.U.Th.’s facilities management sought HMI/SCADA software to monitor and manage the entire system.

Alternate Campus Overview HMI/SCADA Display

Alternate Campus Overview HMI/SCADA Display

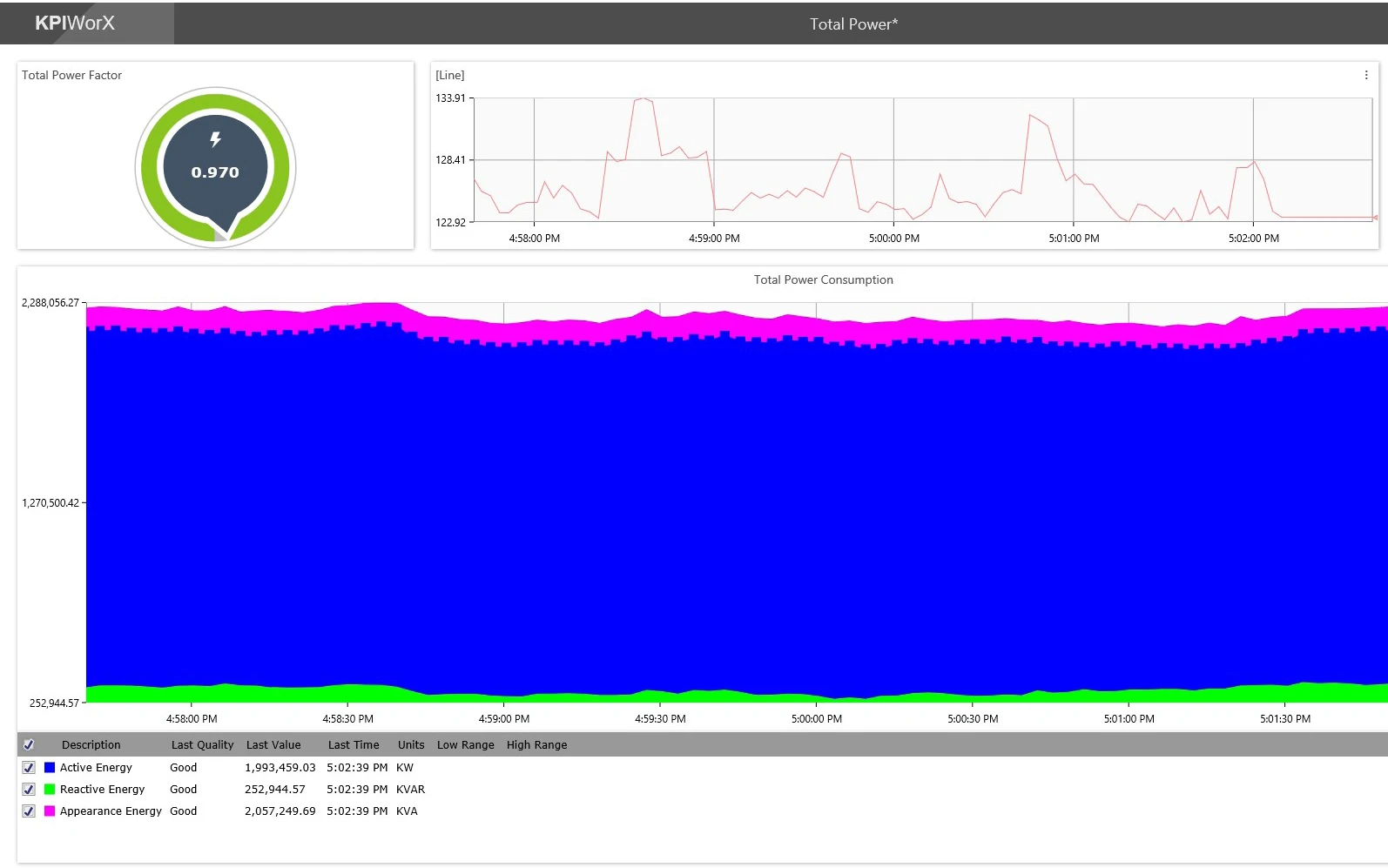

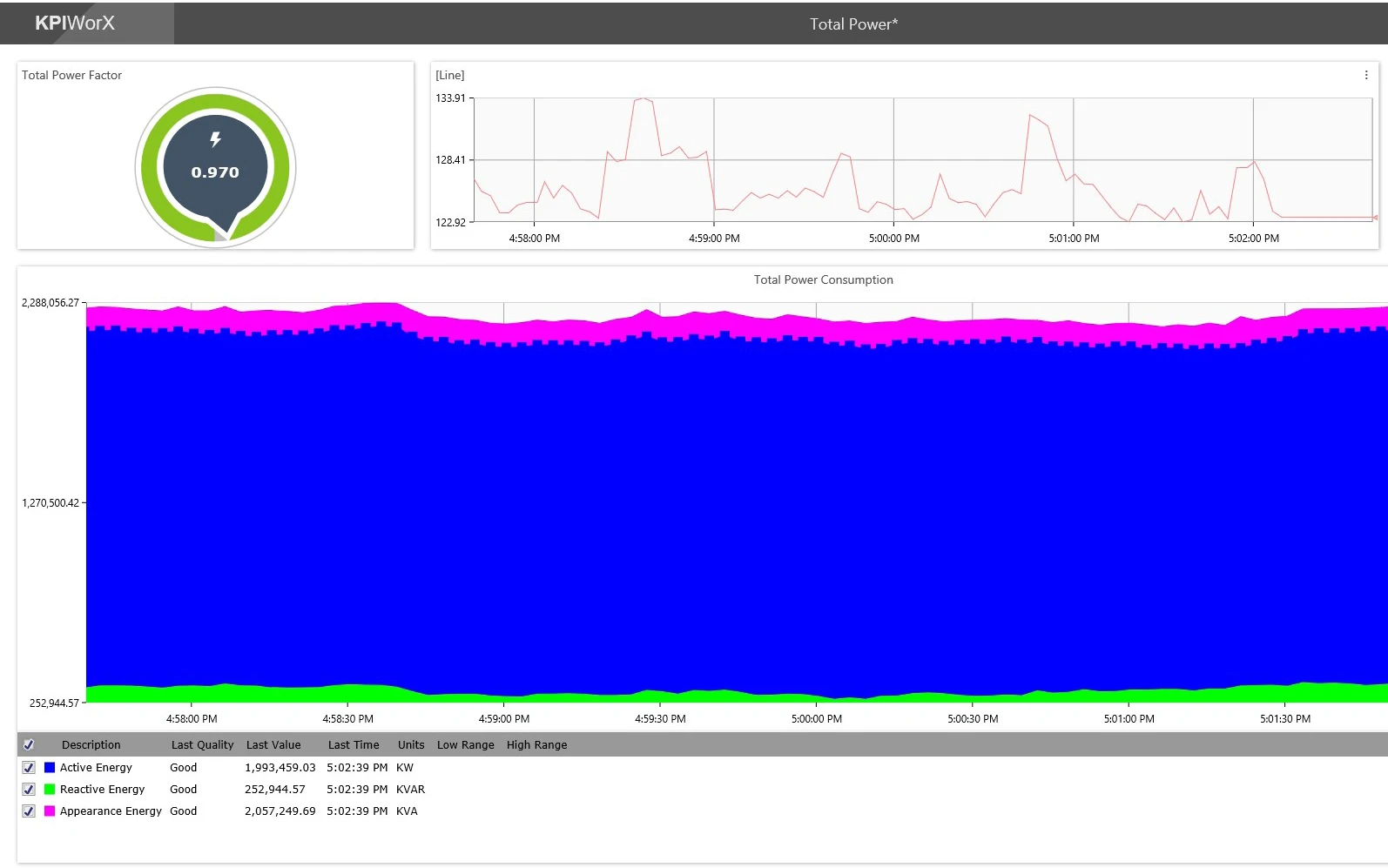

KPI Dashboard Overview

KPI Dashboard Overview

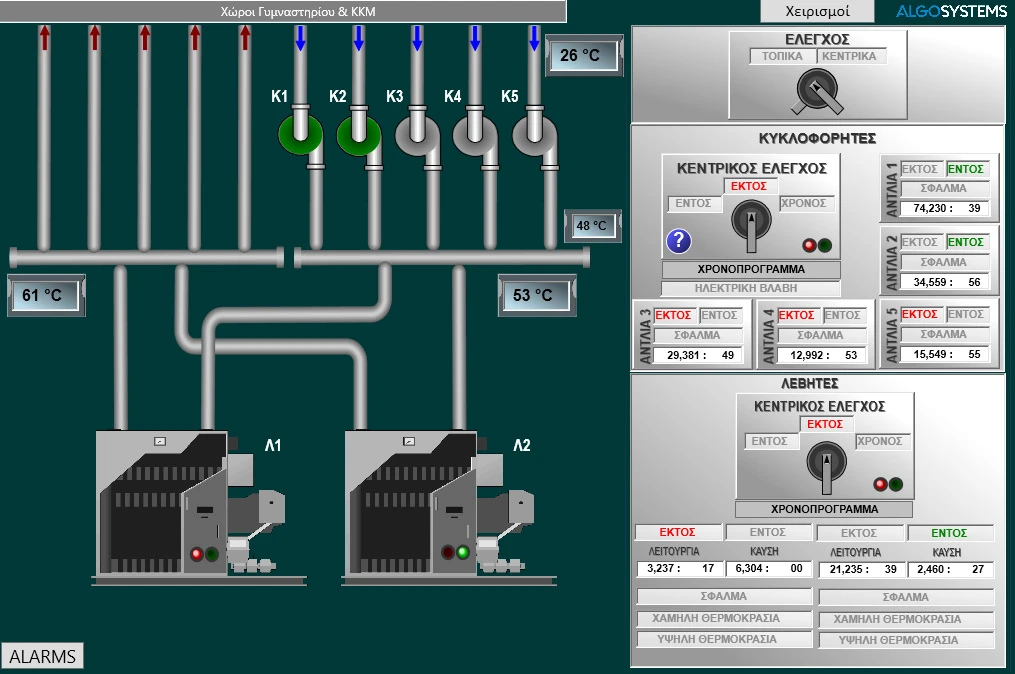

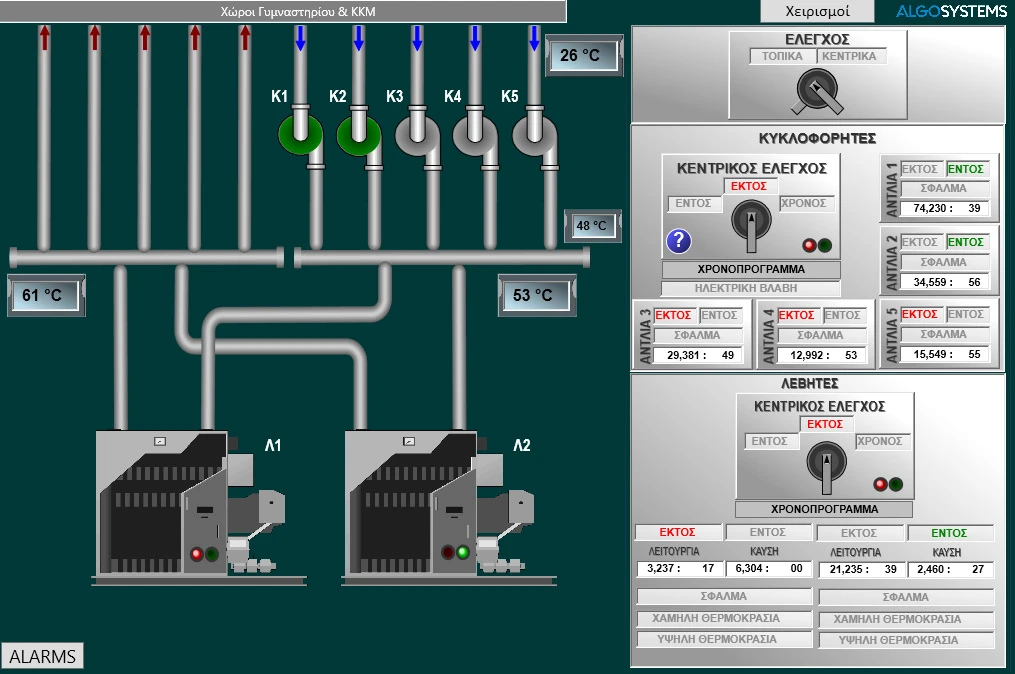

A.U.Th. facilities management, working with systems inte-grator Algosystems of Athens, Greece, realized immediate benefits upon updating their heating network (including implementing new thermostatic switches) and installing their new GENESIS64 building automation and HMI/SCADA software solution. The new system now monitors the continuous operation, temperatures, and levels of the boilers in addition to simultaneous recording of the indoor temperatures of the connected buildings.

The system also measures the water temperature flow and return to the district boiler room and the flow temperatures and return to the exchangers for each building. With the gathered data, A.U.Th. facilities management was able to empirically optimize boiler room and heating network operations, resulting in reducing the number of hours of individual boiler use. In some instances, the required heat output that may have previously utilized five separate boilers could now be handled by three or two, and, in some cases, only one.

At the same time, through the data acquired from GENESIS64, it was determined that the previous set water temperature of 110° C (230° F) was no longer required to mitigate heat loss within the heating network. A.U.Th. facilities manage-ment found that they could lower the temperature to 90° C (194° F) and still maintain the required thermal inertia within the heating network and connected buildings.

Within the first year of operating its new managed heating system, A.U.Th. cut 35.6 percent off its annual energy con-sumption compared to the previous year, translating to over 280,000 euros saved. The following two years after installation brought especially cold and long winter weather, but still resulted in an average of eight percent off year-over-year in energy consumption, even after A.U.Th. decided to extend the university library’s daily hours of operation by five hours.

KPI Dashboard Overview

KPI Dashboard Overview

Boiler Room Overview Developed with GENESIS64

Boiler Room Overview Developed with GENESIS64

Facilities management personnel at the Aristotle University of Thessaloniki are pleased with the measured improvements in their heating network’s energy consumption over the past years. They also continue to anticipate low energy consumption into the coming years due to the physical updates to their heating system and the continued monitoring and management through GENESIS64.

Boiler Room Overview Developed with GENESIS64

Boiler Room Overview Developed with GENESIS64