Category: Manufacturing

PGT Industries

North Venice, Florida, United States

Category: Manufacturing

North Venice, Florida, United States

“Mitsubishi Electric Iconics Digital Solutions' GENESIS Productivity Analytics, in addition to identifying issues, has been used to drive a cultural change in the company […] This system has been a great success and the production capacity found to exist in the current plants has exceeded any expectation.”

PGT® pioneered the U.S. impact-resistant window and door industry and is now the nation’s leading manufacturer and supplier of residential impact-resistant products. It is also one of the largest window and door manufacturers in the United States.

Founded in 1980, PGT employs over 1,000 people across its manufacturing facilities, glass laminating and tempering plants, and delivery fleet operations in Florida. PGT products are sold through a network of more than 1,300 independent distributors.

The company&rsquos full line of custom windows and doors is available throughout the eastern United States, the Gulf Coast, and an expanding international market—including the Caribbean, South America, and Australia.

PGT’s product portfolio includes:

PGT Industries is a wholly owned subsidiary of PGT, Inc. (NASDAQ: PGTI).

“Mitsubishi Electric Iconics Digital Solutions' GENESIS Productivity Analytics, in addition to identifying issues, has been used to drive a cultural change in the company […] This system has been a great success and the production capacity found to exist in the current plants has exceeded any expectation.”

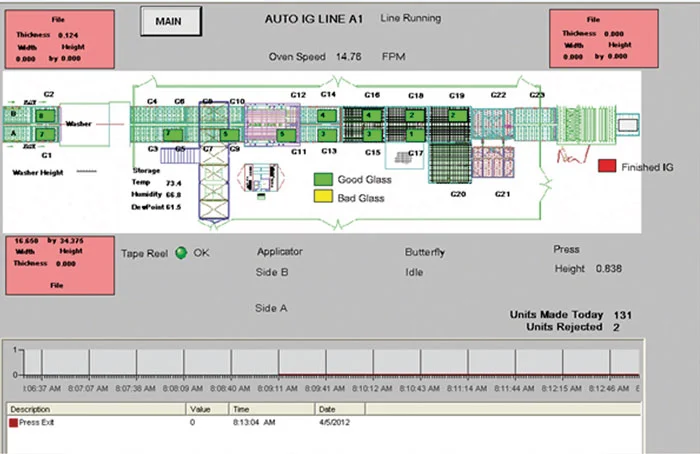

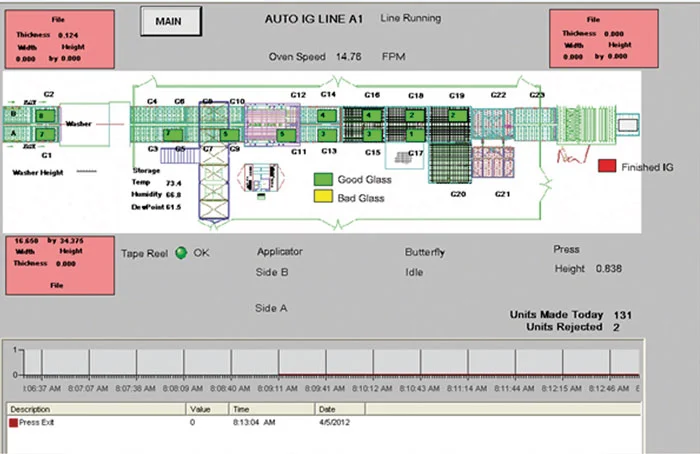

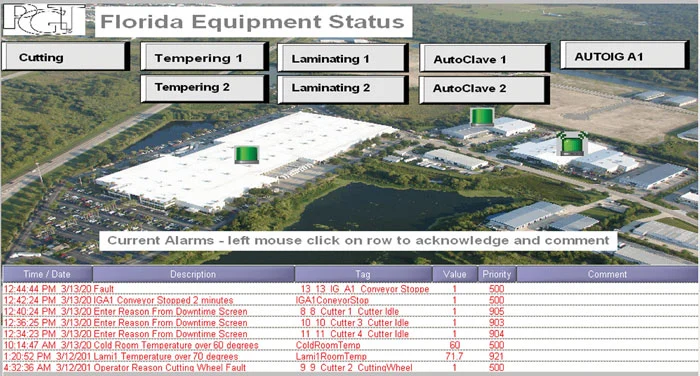

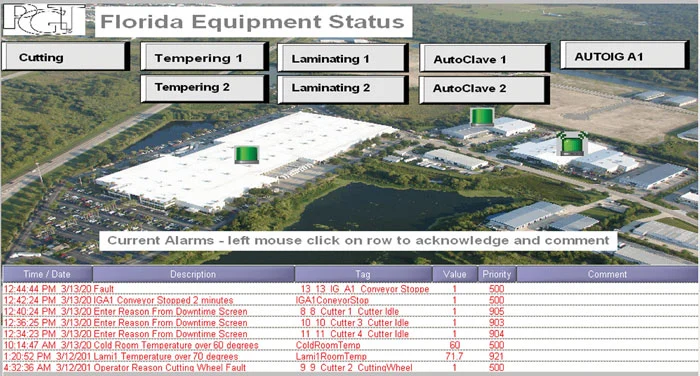

A Control Screen for PGT Insulated Glass Assembly

A Control Screen for PGT Insulated Glass Assembly

PGT Industries selected GENESIS Productivity Analytics visual OEE/KPI/analysis software as its manufacturing intelligence system, along with the GENESIS™ HMI/SCADA suite to integrate all automation equipment.

The GENESIS suite deployment includes:

In addition, PGT Industries implemented:

A Control Screen for PGT Insulated Glass Assembly

A Control Screen for PGT Insulated Glass Assembly

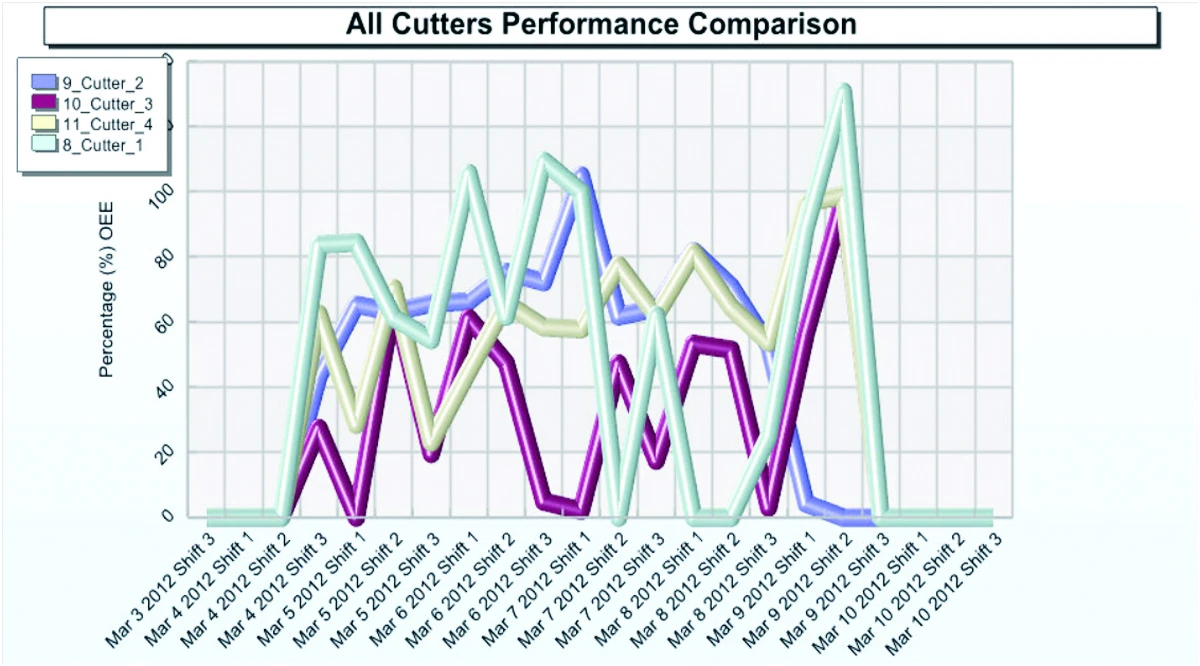

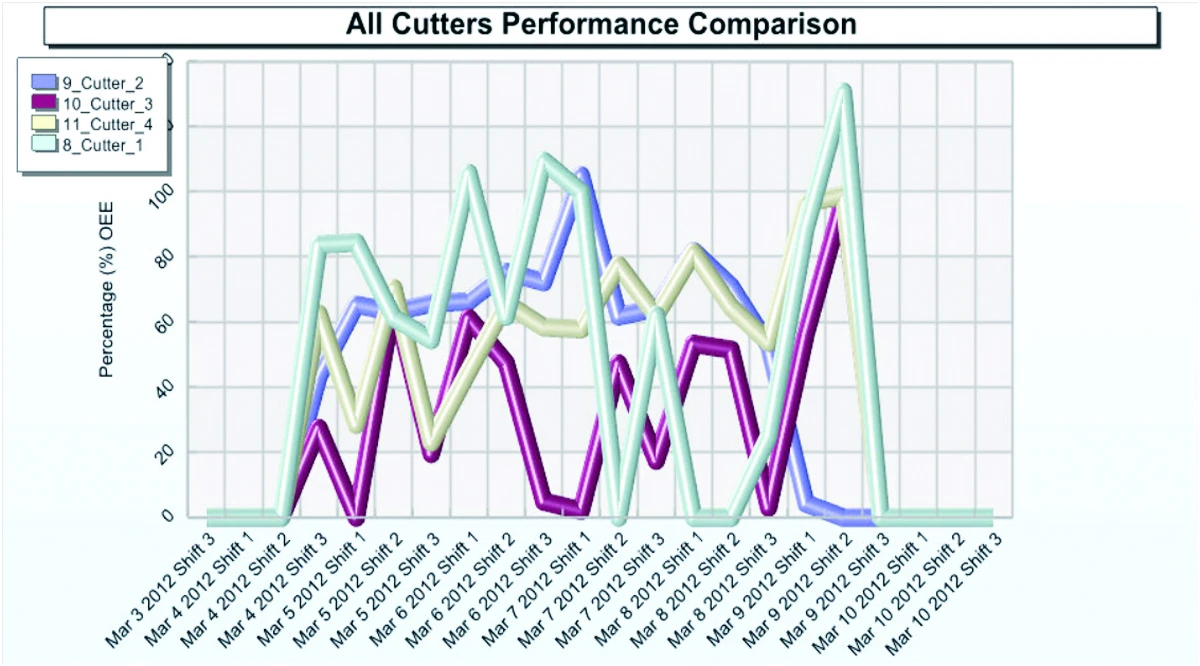

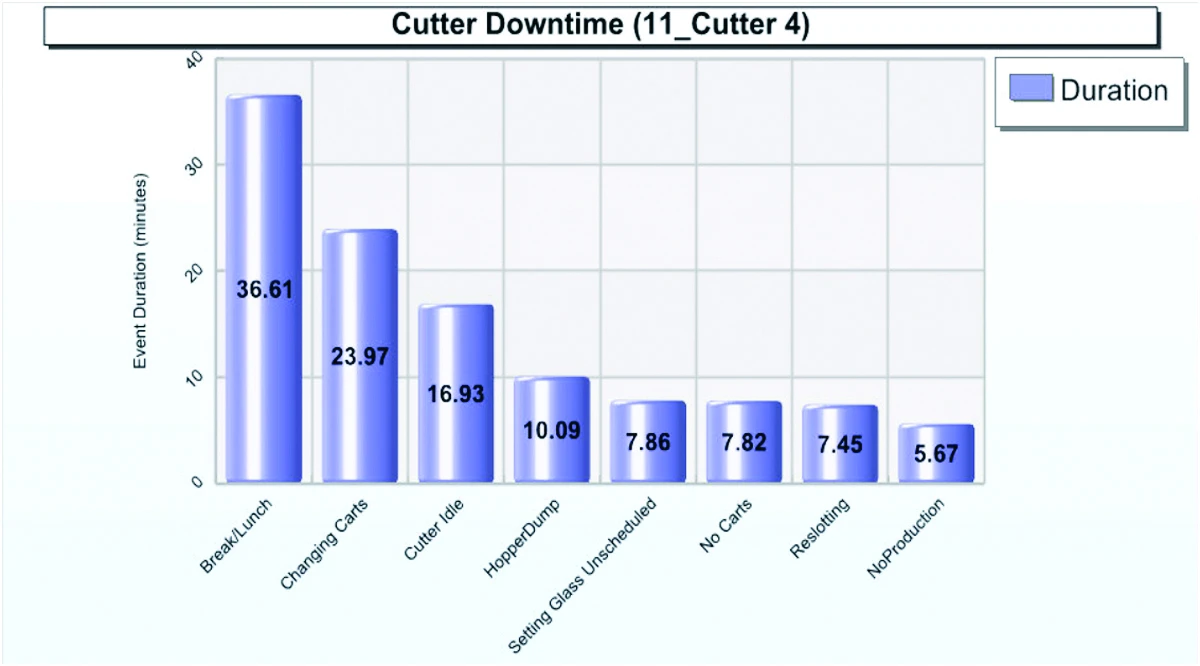

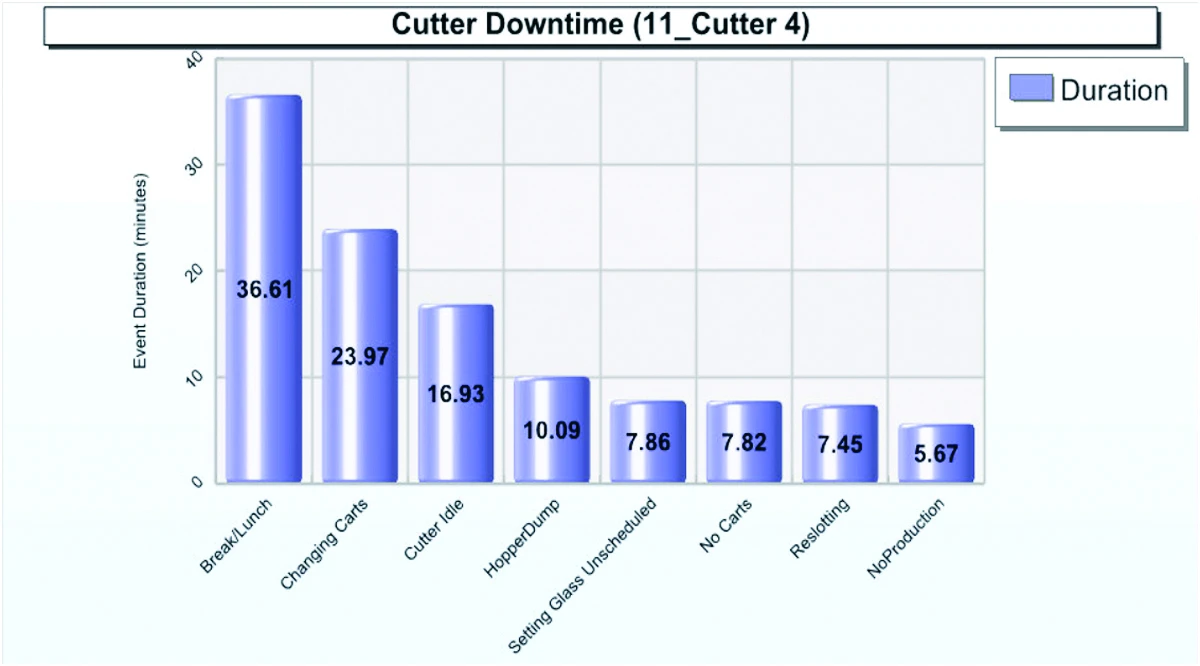

Performance Comparison of Glass Cutters

Performance Comparison of Glass Cutters

PGT Industries operates its glass manufacturing facility in North Venice, Florida. A few years ago, the company projected that demand would soon exceed production capacity and constrain revenue growth. In response, leadership developed a capital plan to expand operations.

However, before executing the expansion, the Vice President of Operations chose to test the assumptions about current capacity by applying a productivity analysis tool.

Implementation and Findings

Mitsubishi Electric Iconics Digital Solutions’ Productivity Analytics software was applied to the plant’s 12 most critical production assets to measure Overall Equipment Effectiveness (OEE). Using drilldown and correlation capabilities, the software identified key sources of OEE loss across three factors:

Before installation, most inefficiencies had been reported as equipment capacity problems. Once Productivity Analytics was online, the data revealed numerous immediate issues visible at all organizational levels, including:

Actions and Results

After uncovering these issues, PGT created work teams to quickly address downtime and production gaps. Productivity Analytics continues to provide real-time, accurate data to both plant operators and management. Any deviation from ideal production rates is flagged immediately, and any downtime exceeding a set threshold is broadcast company-wide so all available resources can be redirected to resolve the issue.

Decision Process

PGT evaluated competing solutions but ultimately chose GENESIS, citing its complete toolset and ease of configuration. The company’s manufacturing technology team quickly learned, configured, and deployed the system—an effort made possible because competitor products were deemed overly complex.

Performance Comparison of Glass Cutters

Performance Comparison of Glass Cutters

Productivity Analytics Allows for Auditing at the Corporate Levels

Productivity Analytics Allows for Auditing at the Corporate Levels

A critical need of the system was the ability to integrate data from many existing equipment systems, so that all interrelated issues could be seen and analyzed. The GENESIS system, including Productivity Analytics, integrates with the following equipment and data:

Productivity Analytics Allows for Auditing at the Corporate Levels

Productivity Analytics Allows for Auditing at the Corporate Levels

A PGT Web-based Portal, Integrated with GENESIS™, Showing Current Alarms

A PGT Web-based Portal, Integrated with GENESIS™, Showing Current Alarms

With the launch of its OEE program and the implementation of Productivity Analytics across all processes, PGT now receives continuous, real-time data reporting at every management level.

Within the first year, the company identified and implemented improvements that increased production output using existing assets. As a result, the planned plant expansion was canceled, delivering major cost savings.

Operational Gains

Following improvement programs guided by Productivity Analytics, the plant achieved higher production rates while running only five days a week instead of seven to meet demand. This shift resulted in an approximate 20 percent reduction in labor and energy costs.

Cultural Transformation

Beyond operational efficiency, Productivity Analytics has driven a cultural change within PGT.

Long-Term Expansion

The success of the system exceeded expectations. With productivity capacity discovered in existing plants, PGT has expanded the scope of Productivity Analytics from the initial 12 assets to approximately 80 assets over three years.

A PGT Web-based Portal, Integrated with GENESIS™, Showing Current Alarms

A PGT Web-based Portal, Integrated with GENESIS™, Showing Current Alarms

Productivity Analytics revealed previously hidden losses in production capacity, giving PGT the transparency it needed to take corrective action. Today, the system serves as the foundation for benchmarking and performance measurement, embedding a culture of continuous improvement centered on Overall Operational Effectiveness.

By leveraging GENESIS, PGT has transformed its operations—achieving measurable efficiency gains, fostering accountability at every level, and ensuring long-term competitiveness. With these advancements, PGT’s manufacturing now runs as smoothly and reliably as the glass it produces.