Category: Government and Military , Transportation

Autocesta Zagreb-Macelj Ltd.

Zagreb, Republic of Croatia

Category: Government and Military , Transportation

Zagreb, Republic of Croatia

“PrecisionX greatly improved our insight into the system and its crucial elements. It is comprehensive but intuitive.”

The Autocesta Zagreb-Macelj Ltd. was established in March 2003 by government decision of the Republic of Croatia. The company’s purpose is to finance, build, operate, and maintain the Zagreb-Macelj Motorway and all related facilities. Its mission is to maintain traffic safety at the highest level and to attract a larger number of travelers, thus creating economic as well as overall development in areas along the motorway. The mission also includes attaining environmental and energy sustainability and efficiency. The company aims at maintaining proper management, maintenance, and modernization to provide the highest level of safety and comfort to make this highway attractive for the transport of both people and goods.

The motorway is part of a highway network in the Republic of Croatia located in the European traffic corridor of the Xa and Phyhrn motorway (Nurnberg-Graz-Maribor-Zagreb) which connects Croatian motorways with European motorway networks. Beginning on the Jankomir interchange on the Bregana-Zagreb-Lipovac motorway, the Zagreb highway is 59.2 kilometers in length, passing through the Zagreb and Krapina-Zagreb counties and ending at Macelj at the international border crossing with the Republic of Slovenia. The entire section consists of 6 tunnels with 6 junctions in between and includes a “closed” toll payment system with two frontal toll stations and four toll stations at the interchanges. The Zagreb motorway is considered one of the best highway connections between Middle and North European countries and South and South-East European countries and the Adriatic Sea.

“PrecisionX greatly improved our insight into the system and its crucial elements. It is comprehensive but intuitive.”

Autocesta Zagreb-Macelj Command Center

Autocesta Zagreb-Macelj Command Center

The Autocesta Zagreb-Macelj needed an advanced system that could enhance the existing SCADA and that could allow traffic monitoring and management and motorway maintenance from a single centralized point in Krapina (COKP Krapina). Since the company preferred a .NET-based platform, they chose system integrator LED Elektronika Ltd., a R&D company also located in Zagreb, Croatia that has experience in installing and implementing intelligent transportation systems and extensive experience in customer .NET application development. LED Elektronika performed a market survey to search for an optimal SCADA solution that could provide scalability (for small and large projects), a high level of customization (open architecture), redundancy (for high-availability systems), and great UI/ UX flexibility (for excellent designs with fully customized views). The company then conducted an in-depth analysis and testing of several software options and chose Mitsubishi Electric Iconics Digital Solutions’ GENESIS64™ as this platform proved to be the best candidate with all the necessary capabilities.

Autocesta Zagreb-Macelj Command Center

Autocesta Zagreb-Macelj Command Center

Master Device View

Master Device View

Master Device View

Master Device View

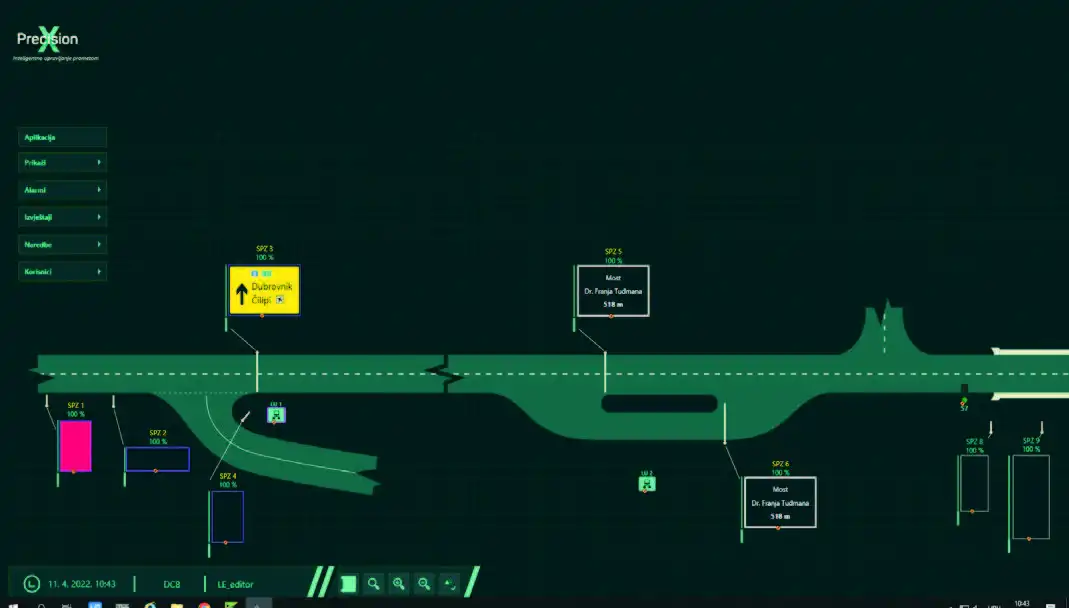

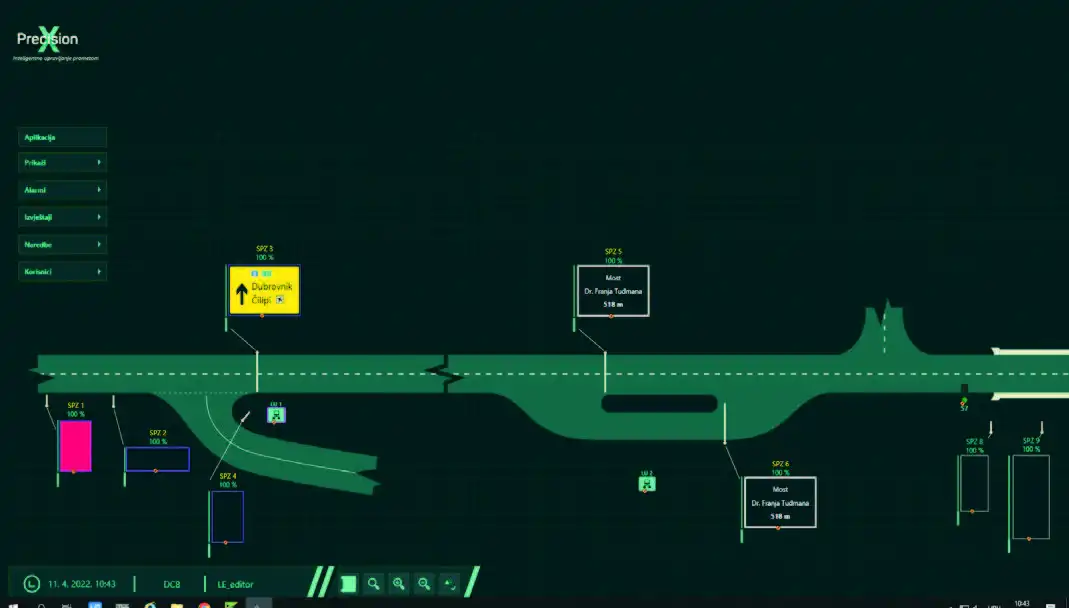

PrecisionX Layout

PrecisionX Layout

Initially, LED Elektronika was using their PrecisionX SCADA system to collect, store, and process traffic data in real-time and present it to operators in the Krapina Traffic Center. This capability resulted in real-time reliable traffic surveillance and management which are crucial for road safety. LED Elektronika was able to implement an advanced system by enhancing their PrecisionX SCADA solution on top of the GENESIS64 SCADA resulting in technology designed specifically for transportation, particularly tunnel and road automation. Setting up the backend (assets, data connections, and data collection/alarming) was completed in a couple of weeks instead of months, thereby rapidly accelerating the implementation stage. Using assets, LED Elektronika was able to take an object-oriented approach with the data model which was important to make a swift transition from custom developed .NET applications to Mitsubishi Electric Iconics Digital Solutions’ GENESIS64. Since the workforce hours involved were reduced by 5x to 7x, the engineering and development costs for the backend were reduced while at the same time system redundancy and scalability were preserved. Additionally, the engineering and development costs of the front-end resulted in a 2x to 4x reduction in workforce hours along with a preservation of backward compatibility (presenting the GUI via web browsers). The GENESIS GUI layout design capabilities with panels and vector graphics provide high quality and responsive designs, and using the dynamics on the objects provides effects that meet user expectations.

Now, several levels of automatic scenarios and algorithms can be implemented in the system. In the field with local controllers, an automated workflow is implemented to ensure the regulation of traffic flow, depending on the data from the traffic detectors, fire sensors, cameras, and wind and air quality sensors. In the Control Center, a global workflow is implemented, thus coordinating multiple field devices to ensure global traffic regulation and flow over the entire section of the road. In case of a fire, a fire response scenario is activated, bypassing all active algorithms to ensure smoke and fire localization (stratification and ventilation of tunnels) and to secure traffic regulation and traffic rerouting with the primary focus of saving human lives. Operators can also initiate manual control of the system to directly control equipment in the field via an intuitive interface. And if needed, multiple commands can be sent simultaneously to individual devices or selected groups of devices.

To achieve optimal user experience and to ensure smooth performance of the system at the same time, LED Elektronika developed a wide range of custom features which include the following:

LED Elektronika then decided to test the limits of just how extensible the GENESIS64 platform could be. While the TLS2002 BASt protocol had been mainstream in road traffic systems and the intelligent transportation system (ITS) industry for the last 40 years, it was not commonly found on the supported protocol list of any industrial automation SCADA system. But thanks to Mitsubishi Electric Iconics Digital Solutions’ Extensibility ToolWorX training and some dedicated collaboration, LED Elektronika was able to develop a custom point manager that plugged seamlessly into the communication layer of the SCADA system. In addition, since redundancy is a relevant part of the system, client and server redundancy were implemented on site due to the high requirements of the overall system stability.

PrecisionX Layout

PrecisionX Layout

The Autocesta Zagreb-Macelj and LED Elektronika teams have had an excellent overall experience in implementing the project. They are quite satisfied and impressed with the new application, especially with the modern user interface design combined with the system’s high-level of performance and impressive scalability. The enhanced system allows more data to be acquired with better representations (graphs, charts, etc.). Additionally, with the more intuitive interface and in-depth view of equipment and overall system status, the number of actions needed to be completed by operators in everyday use has been significantly reduced. To add to this positive experience, Mitsubishi Electric Iconics Digital Solutions proved to be exceptionally fast in responding to and solving problems.

Currently, the Autocesta Zagreb-Macelj and LED Elektronika are adding features to get a better overall user experience. In particular, the Autocesta Zagreb-Macelj plans to expand the PrecisionX SCADA system by adding one more traffic subsystem that will allow operators to monitor and manage traffic flow. They will have the option to manage more traffic signs and monitor relevant traffic data. The next step is to integrate traffic devices such as traffic detectors and traffic lights. LED Elektronika also plans to add a screen recording feature in the SCADA system. In the near future, they would also like to extend the user interface with augmented reality (AR) features and are considering leveraging Mitsubishi Electric Iconics Digital Solutions Hyper Historian™ for its more advanced, asset-centric data collection capabilities.