Category: Manufacturing , Automotive

Comau Pico

Dearborn, Michigan, USA

Category: Manufacturing , Automotive

Dearborn, Michigan, USA

“Mitsubishi Electric Iconics Digital Solutions software allows usage on multiple product lines using the same architecture, thereby increasing through put and decreasing implementation time. GENESIS reduces the number of databases on a system typically from 8 to 4, and allows PLC development software to run on PCs during the production process. GENESIS also accelerates software modifications to the machines”

Comau Pico is an innovative leader in industrial automation. As a member of the Comau Group, they are part of the largest full-service automotive supplier in the world. With over 50 years of experience in automated assembly tooling, Comau Pico offers an unparalleled scope of engineering and services to the North American market. Using the latest technology, they deliver complete turnkey systems and continually meet and exceed the design and manufacturing needs of their customers. Comau Pico is an Authorized OEM of Mitsubishi Electric Iconics Digital Solutions and uses GENESIS software extensively on their systems.

“Mitsubishi Electric Iconics Digital Solutions software allows usage on multiple product lines using the same architecture, thereby increasing through put and decreasing implementation time. GENESIS reduces the number of databases on a system typically from 8 to 4, and allows PLC development software to run on PCs during the production process. GENESIS also accelerates software modifications to the machines”

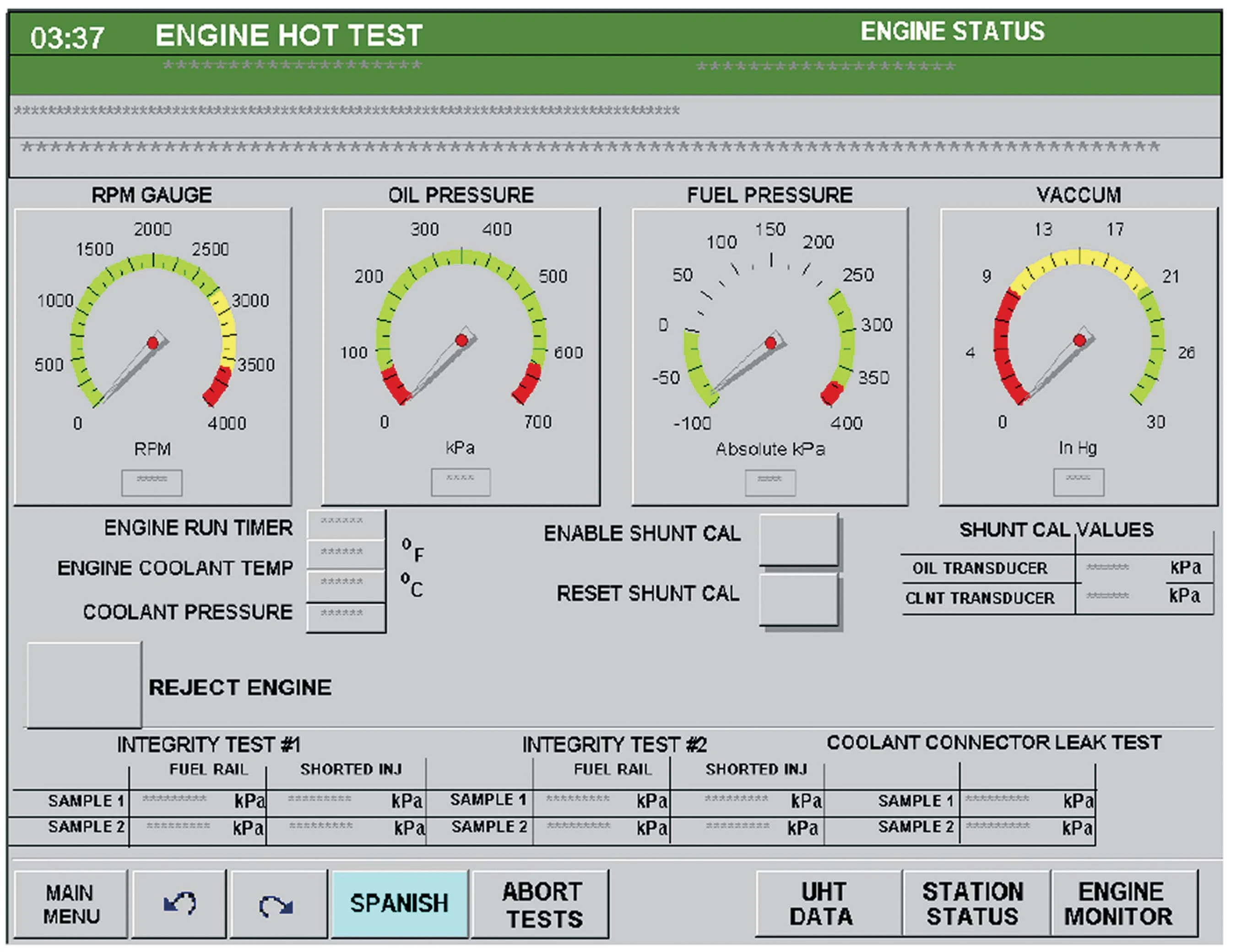

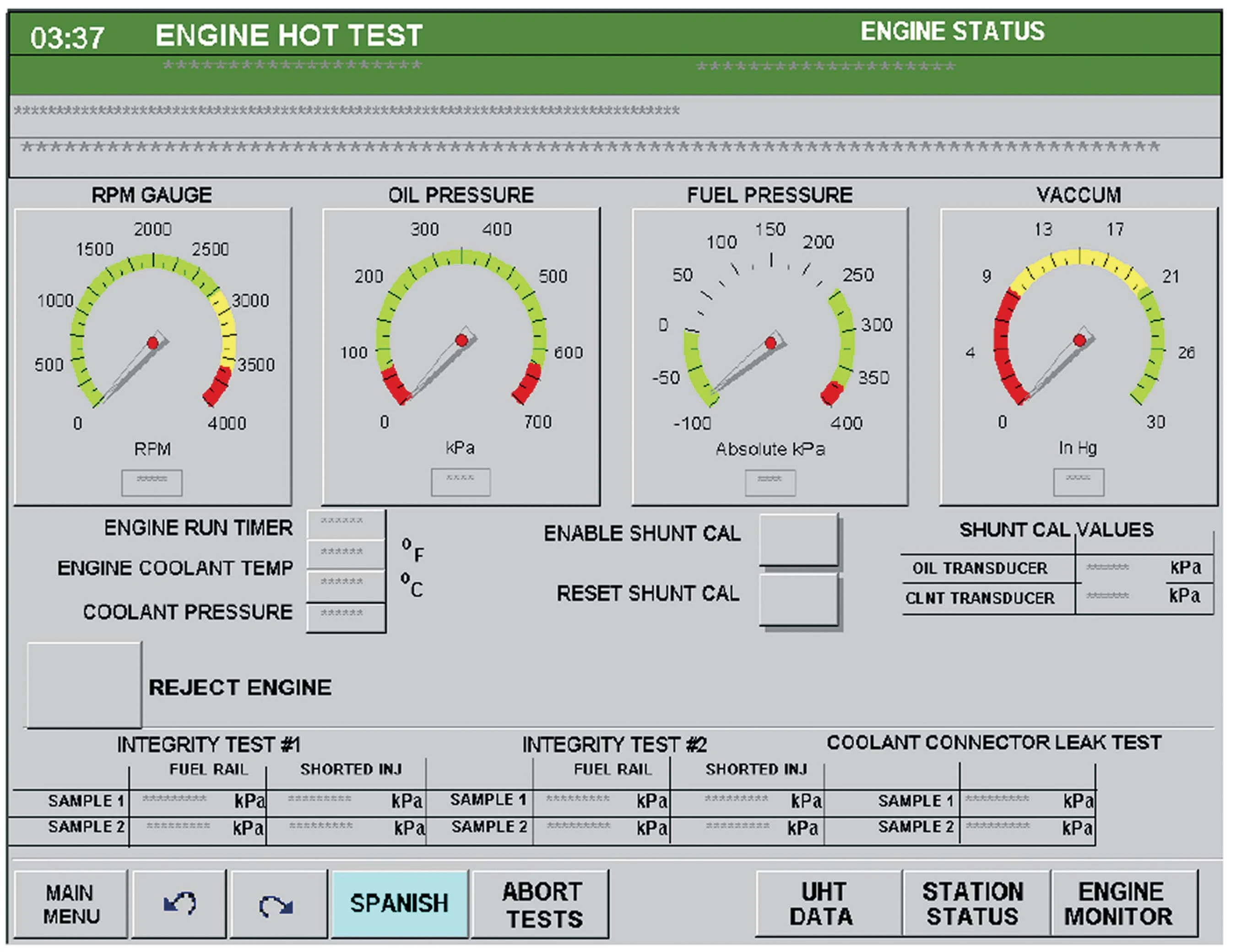

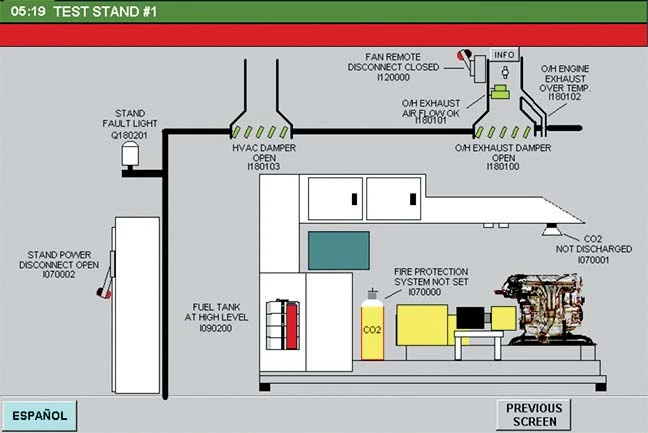

Engine Hot Test Display

Engine Hot Test Display

Comau Pico has installed GENESIS HMI/SCADA software suite (including GraphWorX™, TrendWorX™, AlarmWorX™ and ScriptWorX™) at Ford Motor Company on the engine test stands, designed by Comau Pico at their Dearborn, MI engine plant. Comau Pico has also installed this same software at other Ford plants including those in Mexico and Canada. GENESIS was used primarily for its ease of use, speed and its 100 percent OPC compliant capabilities.

Engine Hot Test Display

Engine Hot Test Display

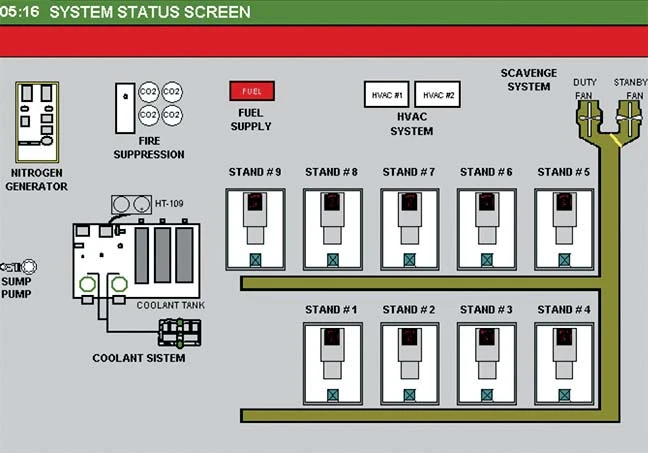

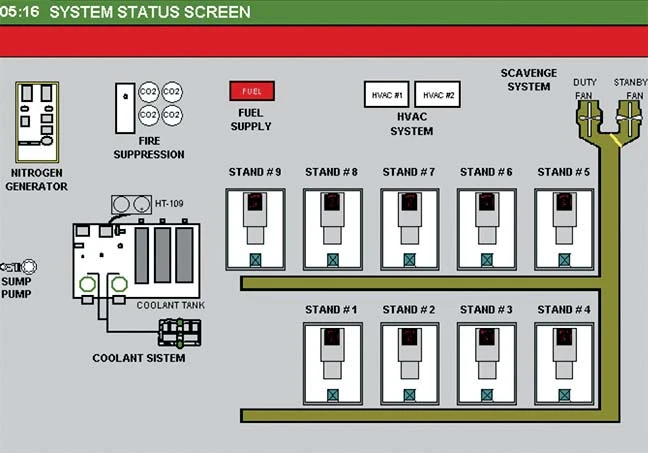

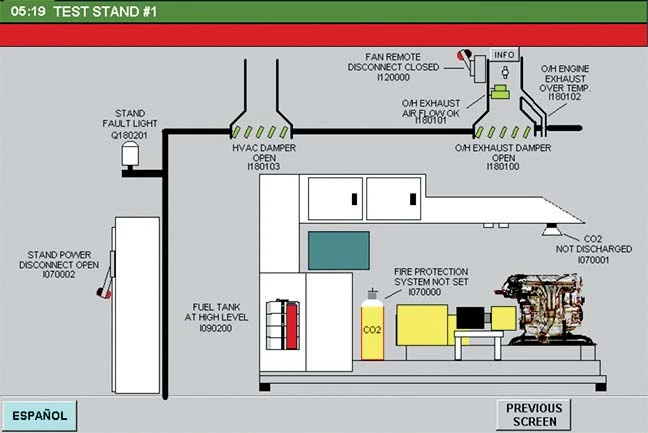

System Status Screen

System Status Screen

Ford Motor contracted with Comau Pico to design and install multiple cold and hot test stands at the Dearborn Engine plant. There are multiple test stands per production line, with each test stand having several hundred tags.

System Status Screen

System Status Screen

Test Stand Monitor

Test Stand Monitor

Ford required 100 percent testing of every engine produced at this plant (4 & 6 cylinder engines) along with the logging and trending of results for both cold and hot testing. Cold testing does not use gasoline and the engine is basically driven by an external motor. All fluids are installed and the engine is run through its cycles. Hot testing involves adding gasoline and actually starting and running the engine through various test cycles.

The test stands perform measurements on the heating and cooling of fluids as well as exhaust gases, spark timing and advancement through the RPM range. Testing is also done on the air combustion mixture of exhaust gases and fuel mixtures of the injection systems. All testing parameters are recorded and trending data stored via LAN to a historical database. Comau Pico has installed over 50 of these engine test stands into six Ford engine plants. Ford is also using GENESIS software on “In Process” test stands at other facilities.

Test Stand Monitor

Test Stand Monitor

Ford uses Mitsubishi Electric Iconics Digital Solutions' DataWorX™ and GraphWorX to enable and sequence the recording of the testing and production area of each test stand. This parameter information is then communicated via the internal Ford Motor local area network to an Oracle®-based database called POSMON®. This testing information is now available to all authorized users who have access to this database, from management to plant floor supervisors. Production rates, failure rates and downtime analysis maintained for each engine production line are used by Ford to schedule preventative maintenance repair and replacements of equipment and systems on the production lines. These performance rates can also be used to manage their supply chain of components and raw materials needed to manufacture engines.

We have worked closely with the Comau Pico Group and Ford Motor Company to make this engine testing project successful in every aspect. Ford Motor Company participates in the Mitsubishi Electric Iconics Digital Solutions SupportWorX maintenance program to keep its software updated and for access to our technical support personnel as needed. Comau Pico continues to expand the use and implementation of our software products in their turn-key solutions that they bring to their automotive customers.