Category: Utilities and Energy , Sustainability

R-CUA

Strasbourg, France

Category: Utilities and Energy , Sustainability

Strasbourg, France

“R-CUA chose Mitsubishi Electric Iconics Digital Solutions first of all for the technological advances in the product, with its web interface, KPIWorX™, and the ease of sharing information between users. R-CUA also chose our products due to the good relationship with the Mitsubishi Electric Iconics Digital Solutions France team, who are open-minded and dynamic. After almost one year of use, we are still satisfied with our choice and the newly announced releases are eagerly awaited.”

R-CUA, headquartered in Strasbourg, France, specialize in the design, financing, development and operation of heat networks (biomass, geothermal energy), power stations and associated energy sources. Also known as the Urban Heat Networks of Alsace, R-CUA/R-CUE maintains 30 million euros worth of capital, with nine heating and cooling system networks over 48 kilometers in Alsace. They provide heat for the equivalent of 30,000 household units.

“R-CUA chose Mitsubishi Electric Iconics Digital Solutions first of all for the technological advances in the product, with its web interface, KPIWorX™, and the ease of sharing information between users. R-CUA also chose our products due to the good relationship with the Mitsubishi Electric Iconics Digital Solutions France team, who are open-minded and dynamic. After almost one year of use, we are still satisfied with our choice and the newly announced releases are eagerly awaited.”

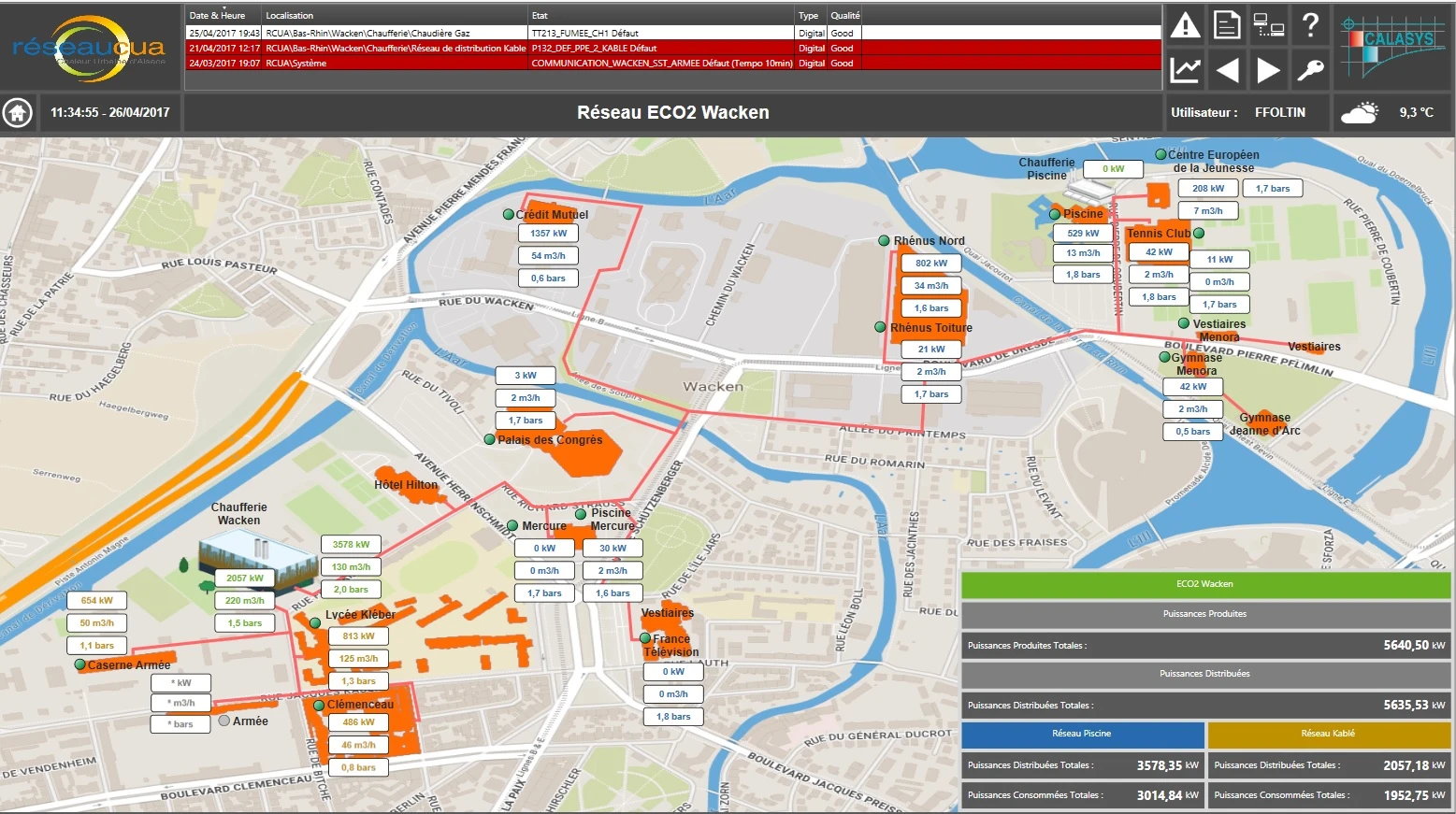

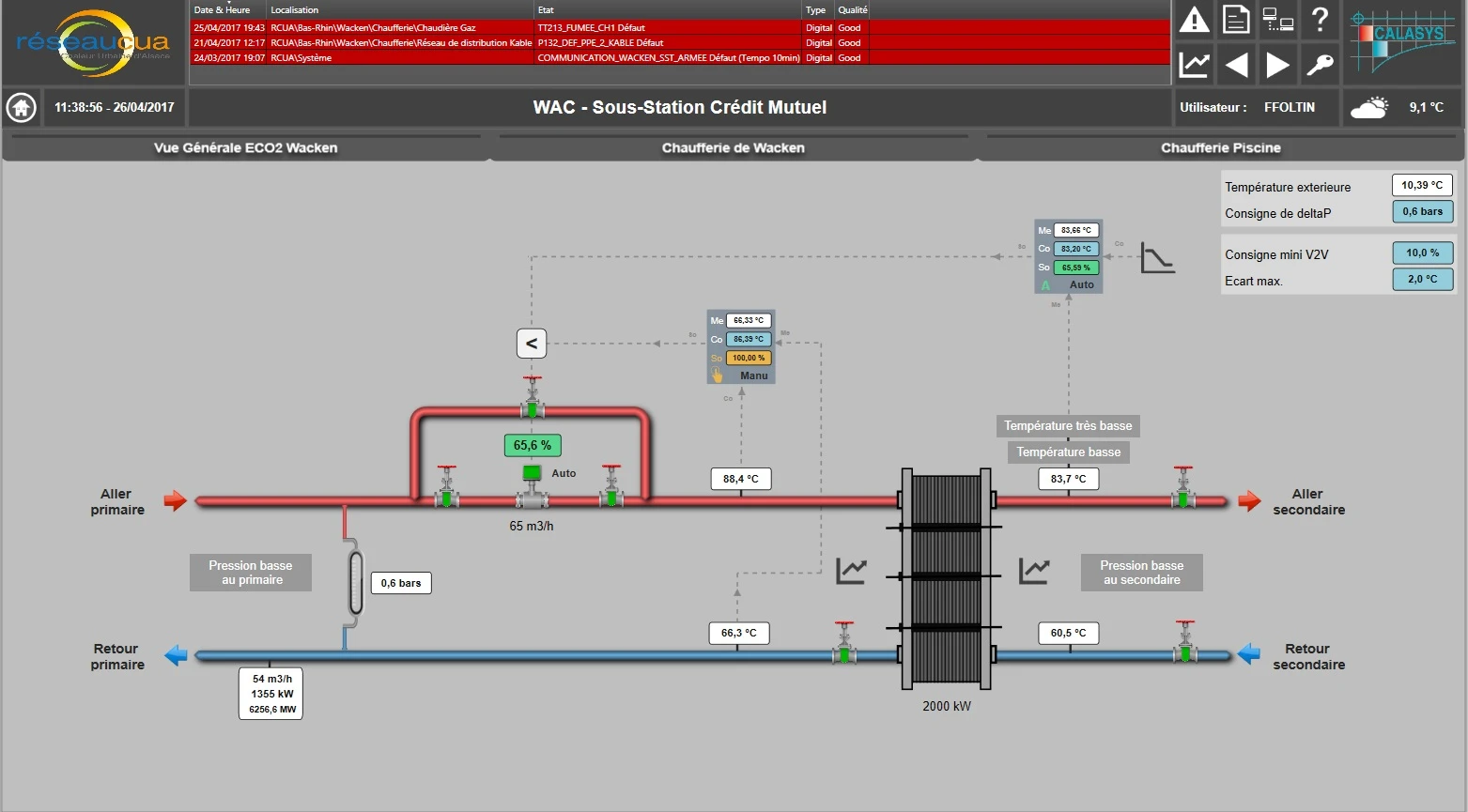

GENESIS64™-Generated Visualization of R-CUA’s Eco2 Wacken Facility

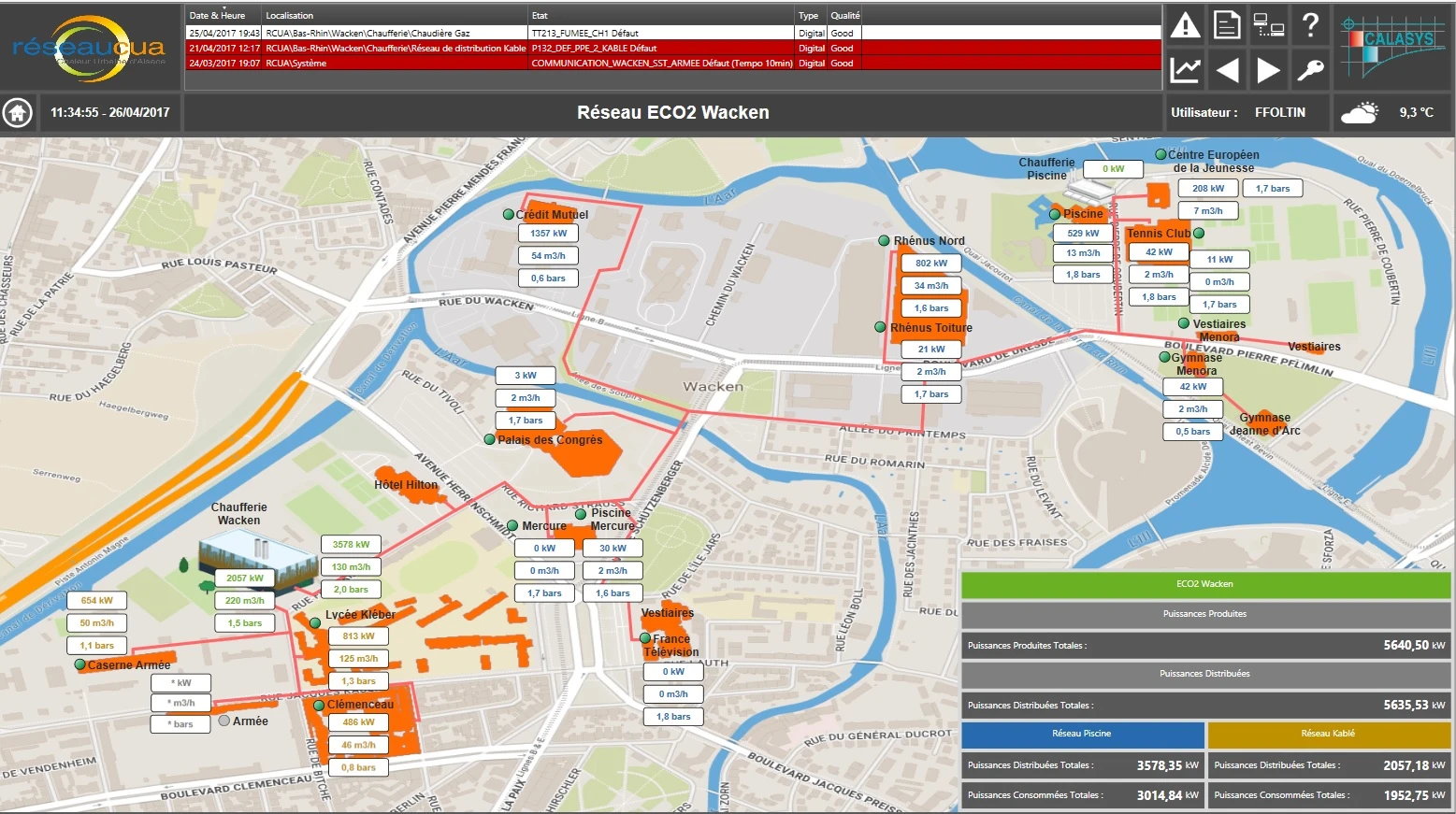

GENESIS64™-Generated Visualization of R-CUA’s Eco2 Wacken Facility

R-CUA, working with system integrator, CALASYS, selected GENESIS64™ HMI/SCADA suite, in addition to the MobileHMI™ data mobility suite and Hyper Historian™ high-speed, reliable, robust plant historian.

GENESIS64™-Generated Visualization of R-CUA’s Eco2 Wacken Facility

GENESIS64™-Generated Visualization of R-CUA’s Eco2 Wacken Facility

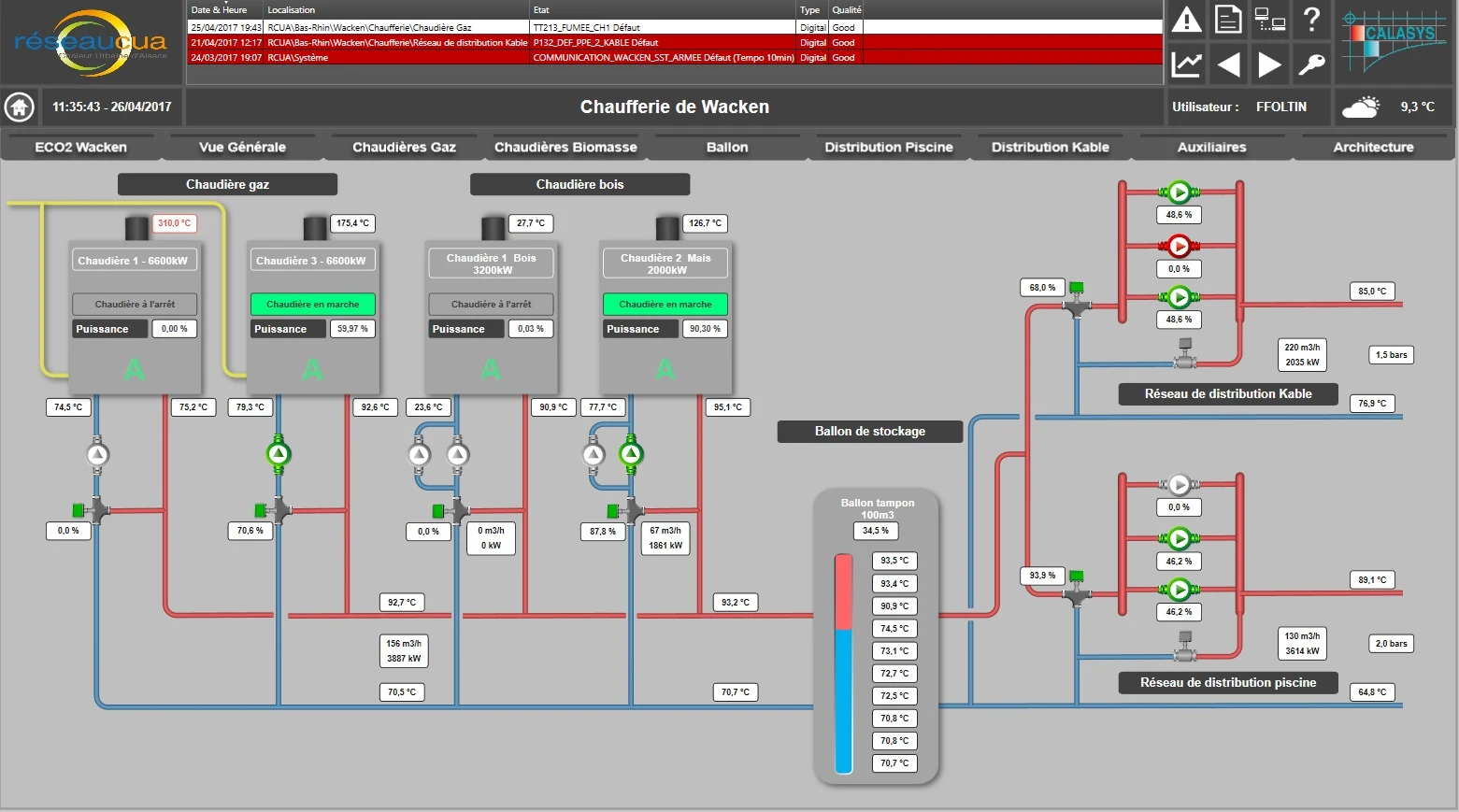

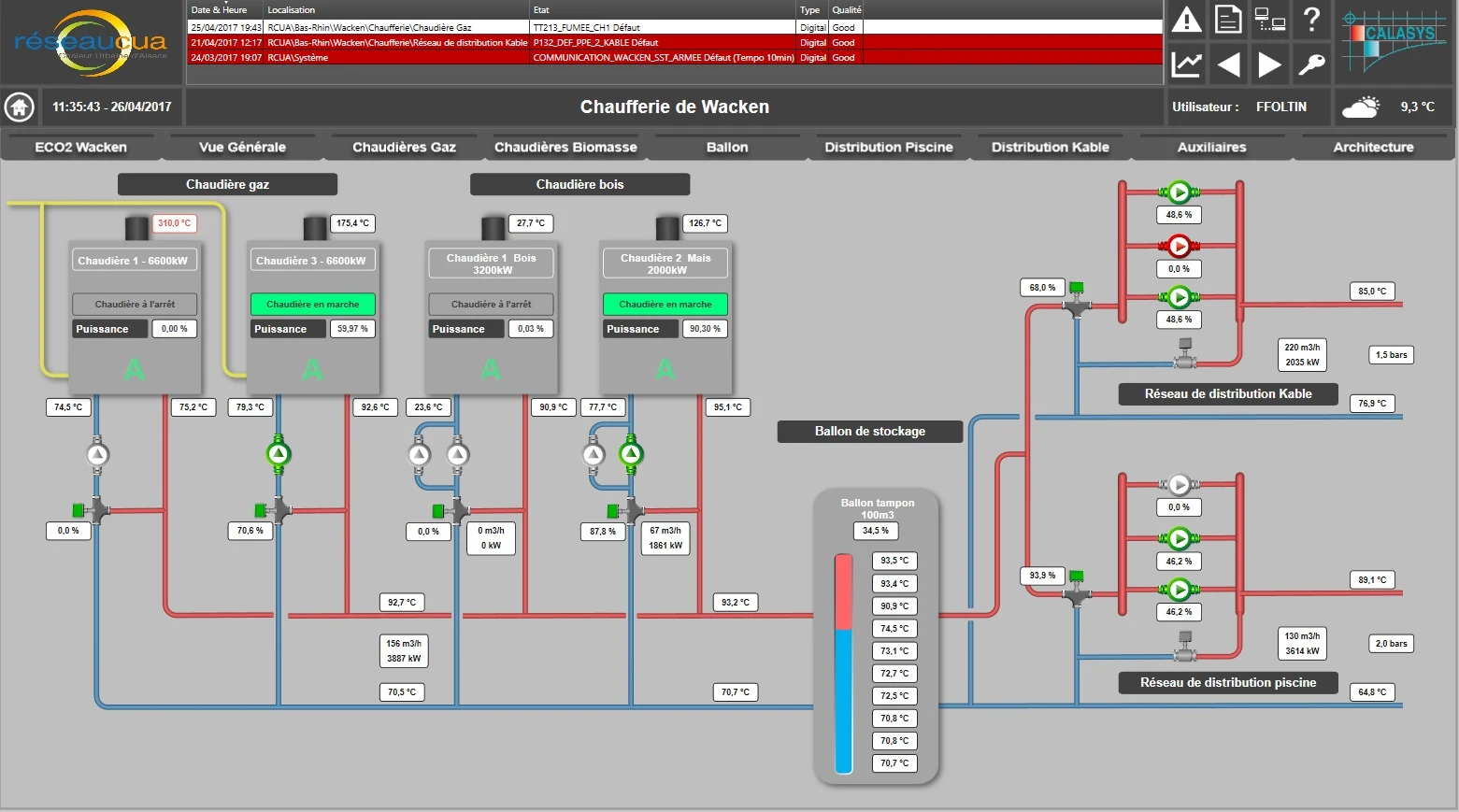

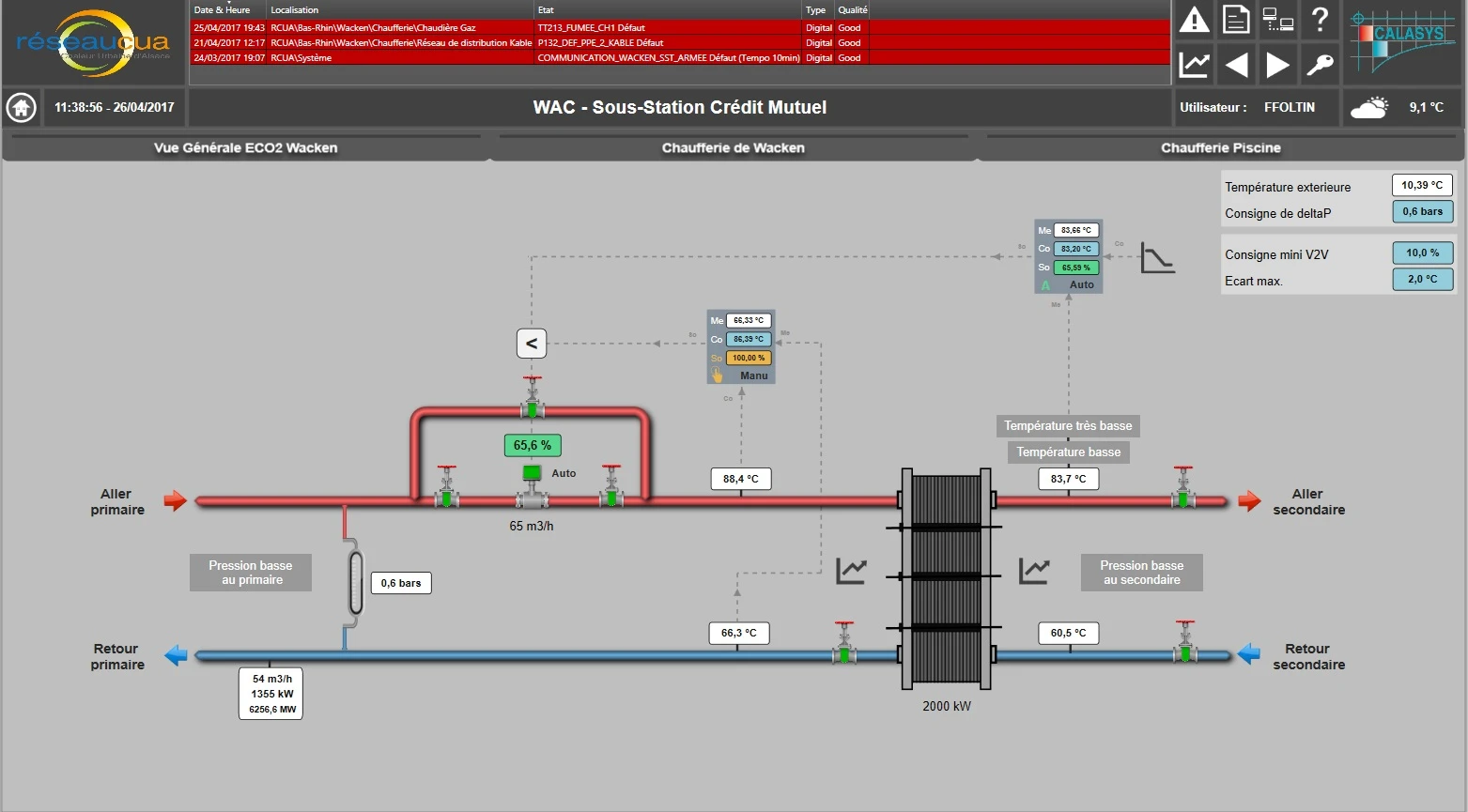

Overview Screen of the Eco2 Wacken Boiler Room Operation

Overview Screen of the Eco2 Wacken Boiler Room Operation

R-CUA sought an automation software solution that would monitor the power plant and heat distribution in the city of Strasbourg in real time. The company required that the software be able to provide information via web browser as well as via mobile devices. In addition, the company sought to manage consumption and potentially save on energy costs.

A primary location involved in the installation is the Eco2 Wacken plant, located in Strasbourg. It includes two wood boilers (at 2MW and 3.2MW) and two gas boilers (each 6MW), for total production of over 17MW of heat. Eco2 Wacken was designed to provide heat for buildings at around 30GWh of heat supply per year, with 87 percent of production via renewable energy. R-CUA’s aim with the wood boilers is to reduce CO2 output in Strasbourg by 7,000 tons per year. The selected automation software solution needed to integrate with multiple BACnet controllers, with three controllers located at the Eco2 Wacken plant. The entire network contains over 2,000 tags, including 16 delivery points, each managed via BACnet controller. The delivery points and the boiler house are connected via 8 kilometers of optical fiber. R-CUA wanted a solution that would work with its existing Microsoft Windows Server machines and Microsoft SQL Server databases, as well as with cloud-based servers and multiple mobile clients.

The new system would replace an existing competitor monitoring solution as well as a boiler-specific HMI, both of which were no longer sufficient for the improvements that R-CUA sought. Newer competitive options were considered before R-CUA, with assistance from CALASYS, settled on Mitsubishi Electric Iconics Digital Solutions.

Overview Screen of the Eco2 Wacken Boiler Room Operation

Overview Screen of the Eco2 Wacken Boiler Room Operation

An R-CUA Substation Control Screen

An R-CUA Substation Control Screen

With our software installed, R-CUA was able to achieve its goal of widely available data access through PC-based clients as well as via mobile devices. Project design was completed within a few months with the first application deployment performed within a week. R-CUA now owns a system that can show its extensive heat network in real time. Every action can be monitored, along with any performance or optimization efforts. With an included performance trend view, operators find it easy to follow the daily operation of the entire network.

An R-CUA Substation Control Screen

An R-CUA Substation Control Screen

R-CUA currently has Mitsubishi Electric Iconics Digital Solutions automation software monitoring all of its plants. The company plans to extend its heating network which will involve the connection to, and supervision of, new boilers. We will be there to ensure the heat stays on.