What You’ll Learn in This Blog

- What universal industrial automation means and how it applies across vertical applications such as SCADA, BAS, EMS, DCIM, MES, and more

- How a configuration-first approach simplifies scalability, reduces risk, and lowers cost of ownership

- Why information technology and operational technology convergence is driving the need for flexible, interoperable automation platforms

- How Mitsubishi Electric’s GENESIS software embodies the principles of universal industrial automation

The Case for Universal Industrial Automation Software

Industrial operations have grown increasingly complex. From process control and building management to manufacturing execution and energy optimization, systems once isolated are now expected to interoperate seamlessly. This growing demand for connectivity and coherence has exposed the limitations of traditional, siloed automation software.

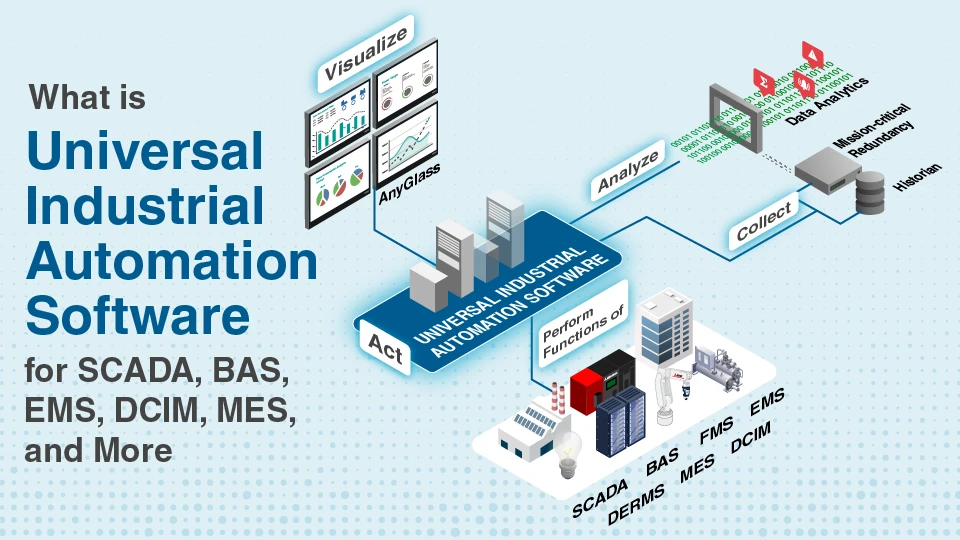

To counter this challenge, organizations are turning to universal industrial automation software, a new model for digital transformation across operations and infrastructure. This approach moves beyond incremental improvement to redefine how automation platforms are designed to be:

- Open for seamless integration and interoperability

- Scalable across systems, facilities, and global networks

- Interoperable to unify technologies and data sources

- Resilient to ensure reliability and long-term performance

By performing the functions of vertical market applications such as Supervisory Control and Data Acquisition (SCADA), Building Automation Systems (BAS), and Data Center Infrastructure Management (DCIM), the platform also enables seamless integration across these systems.

Rather than simply bridging information technology (IT) and operational technology (OT), universal automation unifies data, optimizes performance, and helps organizations remain adaptable amid constant change. This evolution represents a shift toward greater flexibility, simplicity, and sustainability in industrial digitalization.

To see how this transformation comes to life, let’s define what makes automation truly universal.

Defining Universal Industrial Automation Software

Universal industrial automation software is not a product category but a design philosophy. The approach enables organizations to connect every system, control every process, and interpret every data point through a single, scalable software framework.

To grasp how this framework works in practice, consider the six foundational principles that define this software and make this level of flexibility and control possible.

1. Universal: Software That Scales Across Markets

A universal automation platform must adapt to any application, market, and scale, from a single facility or production line to multi-site, global networks. Achieving this level of flexibility requires an elegantly balanced architecture that introduces no unnecessary overhead in small or single-node deployments yet scales effortlessly across wide-area networks with minimal configuration.

By definition, a universal solution must serve diverse sectors without compromise, supporting a full range of systems including:

- Supervisory Control and Data Acquisition (SCADA)

- Building Automation System (BAS)

- Facilities Management System (FMS)

- Energy Management System (EMS)

- Distributed Energy Resource Management System (DERMS)

- Manufacturing Execution System (MES)

- Data Center Infrastructure Management System (with a focus on data center gray space)

This universality bridges systems that were once isolated by establishing a common operational foundation. Data flows seamlessly between applications, enabling organizations to visualize, analyze, and control processes across industries from a single platform. Consistency, visibility, and performance remain intact as organizations expand, modernize, and evolve.

Universal automation software also strengthens cross-domain collaboration, connecting SCADA, BAS, MES, and FMS environments into unified, intelligent ecosystems that enable continuous optimization and innovation.

2. Configurable: Flexibility Without Fragility

True universality depends on configurability or the ability to adapt software quickly and intuitively without extensive coding. Mature, well-designed software provides the fundamental building blocks needed to create any application. Each function is modular and reusable, allowing users to assemble complete solutions by combining predefined components rather than writing custom scripts.

In this configuration-first model, coding or scripting becomes a last resort, not the default approach. Less mature technologies often depend on programming to achieve flexibility, but this reliance creates long-term challenges:

- The need to troubleshoot and debug custom efforts

- The need to document and maintain those efforts

- The need to train others to understand the unique programming styles used

These issues multiply over time, making upgrades and validation far more complex. Every custom feature requires retesting, revalidation, and retraining after software updates, increasing maintenance costs and slowing innovation.

A configuration-first approach eliminates these risks by providing flexibility through structured, modular design. Organizations can build and scale applications with greater speed, reliability, and consistency while reducing total cost of ownership. Configurability delivers the power of flexibility without the fragility of custom code, enabling faster, safer, and more sustainable innovation.

3. Industrial: Engineered for Reliability and Longevity

Industrial automation describes software primarily applied in OT environments across industry, yet equally valuable in adjacent sectors such as building automation and facilities management.

The common thread among these markets is the demand for continuous reliability and a functional architecture built on the Connect, Collect, Analyze, Visualize, and Act framework. This composable design ensures that each function, including connectivity, analytics, visualization, and control, can operate independently or in unison, offering maximum flexibility and resilience.

Industrial systems operate in environments where downtime is unacceptable, from energy and water utilities to manufacturing and smart campuses. Universal automation platforms must therefore deliver round-the-clock reliability (24/7/365) while maintaining scalability and security.

This capability enables organizations to:

- Connect to thousands of devices and protocols simultaneously

- Collect high-resolution data with automated archiving and recovery

- Analyze real-time and historical data to predict and prevent failures

- Visualize operations across desktop, web, and mobile environments

- Act through intelligent alerts, automated workflows, and closed-loop control

These capabilities form the Connect, Collect, Analyze, Visualize, and Act framework that defines modern industrial automation. Universal automation ensures this framework remains resilient, scalable, and ready for continuous innovation.

4. Automated: Closing the Loop Between Insight and Action

In modern industrial environments, visibility alone is not enough; organizations require software capable of transforming data into intelligent, data-driven action. Universal automation addresses this need by integrating intelligence at every level, creating a continuous feedback loop where data drives decision-making and response.

Each functional area in the Connect, Collect, Analyze, Visualize, and Act framework contributes to this closed-loop system:

- Connect provides broad interoperability with read and write functionality across diverse protocols and architectures used in every market, from SCADA and BAS to MES and EMS.

- Collect ensures efficient data archiving with compression, backup, and recovery mechanisms that sustain performance at scale.

- Analyze accesses all available data, including sensor, user-entered, historian, and enterprise sources, to deliver insights, support machine learning, and manage alarms proactively. Analytics continue to advance through asset-based naming structures and Universal Namespace models, simplifying collaboration and accelerating insights.

- Visualize delivers real-time access to information through anyglass technology, allowing users to view, analyze, and manage data from any device or interface, including desktop, web, and mobile environments. This consistent visualization experience ensures clarity and continuity across the entire enterprise.

- Act translates insight into outcomes through intelligent workflows that trigger automated or manual responses as needed.

By bringing these functions together, automation shifts from reactive control to proactive intelligence. Organizations gain the ability to detect anomalies, predict issues, and optimize performance automatically. Automation evolves into a dynamic, learning system that continuously adapts to operational goals and conditions.

5. Software: Built on Quality, Security, and Modern Engineering

Software forms the foundation of universal industrial automation, referring to the ability to select and install off-the-shelf solutions that can be configured to meet the needs of each application.

Modern industrial software must be developed using contemporary methodologies and tools to ensure reliability, agility, and security. These development practices include:

- Agile development practices that support rapid iteration and continuous improvement

- Automated quality testing to maintain performance and stability through every release

- Modern development frameworks that ensure compatibility and scalability across systems

- Adherence to global security and quality standards, including ISO-9001, ISO-27001, IEC-62443, and CMMC certifications

These practices demonstrate a commitment to engineering excellence and security assurance, giving customers confidence that the software is built on a foundation of tested, validated, and continually evolving quality.

6. Platform-Based: Built for Interoperability and Evolution

The final pillar is interoperability or the ability to integrate with virtually any system, data model, or device. A platform-based approach ensures open connectivity across both IT and OT environments, protecting existing investments while enabling innovation.

Universal automation platforms are designed to support a wide range of interoperability standards, including:

- OPC Foundation Standards: OPC Classic and OPC UA

- Networking and Messaging Protocols: REST, MQTT, BACnet, SNMP, Modbus

- Database Connectivity: ODBC, OLE DB, and Sparkplug

- Architectural Frameworks: Unified Namespace (UNS) and CESMII Profiles

These standards enable real-time data exchange across diverse systems and devices, ensuring visibility from the plant floor to the enterprise cloud.

A platform-based design also supports layered functionality, enabling organizations to add advanced capabilities without reengineering the core system. Such capabilities include:

- Bridging tools for data interoperability and system transactions

- Batch automation and management

- Analytics and energy optimization

- Fault detection and diagnostics (FDD) for predictive analytics

- Report generation for regulatory and operational requirements

- Workflow management for multi-step processes and procedures

This layered and open architecture allows universal automation to evolve alongside technology, ensuring adaptability to new standards, systems, and operational needs.

Why Universal Automation Matters Now

Industrial digital transformation is redefining how organizations connect, analyze, and act on data to enhance performance, efficiency, and resilience. Several global trends are accelerating this transformation and shaping the next generation of automation:

- IT/OT Convergence: The line between information technology and operational technology continues to fade as enterprises strive to unify business intelligence with real-time control. Seamless integration across these domains facilitates smarter, data-driven decision-making.

- Workforce Transformation: A new generation of engineers and operators expects intuitive, low-code tools that simplify configuration, accelerate learning, and reduce reliance on specialized expertise.

- Sustainability and Compliance: ESG objectives, energy optimization, and regulatory accountability now demand complete visibility across systems and processes.

Universal automation provides the foundation for this new era of industrial digital transformation. Through unified data, intelligent analytics, and automated control, it turns complexity into clarity and connects every level of operation. More than a technology, universal industrial automation represents a strategy for resilience, innovation, and long-term competitiveness in a rapidly changing world.

GENESIS: Realizing the Vision of Universal Industrial Automation

The vision of universal industrial automation becomes tangible in the GENESIS software platform by Mitsubishi Electric Iconics Digital Solutions, a solution that unites the industrial, building, and energy worlds under one flexible, scalable, and secure architecture.

Universal Foundation Across Industries

GENESIS defines universality in automation and was engineered with that purpose in mind. The software is not a combination of separate systems but a single, composable framework that serves multiple industries, including manufacturing, energy, utilities, transportation, data centers, and smart buildings. Its elegantly scalable architecture grows with the organization, from a single facility to a multi-site enterprise, without changing core code or structure.

This design provides the flexibility and functionality to perform the full range of automation roles from SCADA and BAS to FMS, DCIM, and beyond, delivering consistent reliability, scalability, and performance in every use case. By unifying these capabilities within one adaptable platform, GENESIS allows organizations to standardize on a single solution that integrates data, control, and insight across every level of operation.

Configuration-First Flexibility

GENESIS’s configuration-first design empowers users to build and modify applications intuitively. Predefined modules for alarming, trending, reporting, and visualization support rapid customization without complex programming. This structure accelerates deployment, minimizes errors, and simplifies version control, allowing teams to innovate continuously without accumulating technical debt.

In short, GENESIS transforms configuration into a competitive advantage.

Industrial-Grade Reliability

GENESIS is designed for environments where uptime is mission-critical. Its redundant architecture ensures continuous operation, while its built-in historian delivers rapid, reliable data logging with integrated compression and recovery.

Organizations across industries depend on GENESIS to maintain uninterrupted visibility and control, whether managing airports, tunnels, water utilities, or global manufacturing networks.

Automation and Intelligence in Action

Beyond data collection, GENESIS converts information into actionable intelligence. Analytics, visualization, and alarm management operate together in a closed feedback loop that detects anomalies, predicts issues, and automates response.

With native support for fault detection and diagnostics (FDD), GENESIS drives a transition from reactive maintenance to proactive optimization. The outcome is higher reliability, lower energy use, and measurable operational efficiency across every facility and process.

Platform-Based Interoperability

GENESIS embodies IT/OT convergence through open, standards-based connectivity. The platform supports leading protocols, including OPC UA, MQTT, BACnet, Modbus, SNMP, REST, and Unified Namespace, facilitating seamless communication among legacy systems, modern edge devices, and cloud infrastructure.

Integration with both enterprise and operational systems extends GENESIS far beyond visualization and control; it becomes the backbone of connected intelligent industrial ecosystems.

Universal Automation in Action

GENESIS exemplifies everything universal industrial automation stands for:

- Universal architecture that scales across systems and industries

- Configuration-first flexibility that reduces risk and accelerates adoption

- Industrial reliability that guarantees uptime and performance

- Automation intelligence that transforms insight into action

- Open interoperability that bridges IT and OT for total visibility

Discover how GENESIS delivers the universal industrial automation platform that transforms connectivity into operational optimization.

Download the GENESIS Brochure to explore its architecture, key capabilities, and the value it brings to modern automation.

The advantages of universal automation are wide-ranging, and many organizations are now asking how to apply these principles in practice. The following FAQs address some of the most common questions about universal industrial automation and how GENESIS brings this vision to life.

Frequently Asked Questions About Universal Industrial Automation Software

What makes automation software “universal”?

Universal automation software is designed to work across any industry, system, or scale without major reengineering. It connects diverse technologies through open standards, ensuring interoperability between IT, OT, and IoT environments.

How does universal automation differ from traditional automation?

Traditional automation systems are often siloed and vendor-specific, requiring custom code to integrate. Universal automation uses open, configurable frameworks that allow seamless connectivity, faster deployment, and long-term scalability.

Why is a configuration-first approach so important?

A configuration-first approach lets users build, adjust, and scale systems without programming or scripting. It reduces errors, accelerates deployment, and lowers total cost of ownership.

What role does IT/OT convergence play in industrial automation?

IT/OT convergence enables operational systems to share real-time data with enterprise platforms. This visibility improves decision-making, predictive maintenance, and cross-domain collaboration across manufacturing, energy, and building sectors.

How does Mitsubishi Electric’s GENESIS software embody universal automation?

GENESIS brings together industrial, building, and energy operations within one secure, scalable platform. It delivers configuration-first flexibility, built-in redundancy, and open interoperability through protocols like OPC UA, MQTT, and BACnet.

What are the benefits of adopting a universal automation platform?

Organizations gain improved reliability, reduced integration costs, and faster innovation with the freedom to evolve with changing technologies all while maintaining optimized performance and security.

The Future of Automation Is Universal

As industries continue to evolve, the need for unified, adaptable, and intelligent automation grows stronger. Universal industrial automation provides that foundation, bringing together systems, teams, and data within a single, connected ecosystem.

GENESIS leads this transformation by breaking down silos, simplifying integration, and enabling true industrial digital transformation and IT/OT convergence. Organizations can move beyond incremental improvement toward continuous innovation, efficiency, and sustainability.

Automation today is no longer about isolated control; it is about connected intelligence.

The future is not proprietary. The future is universal.

Ready to modernize your operations?

Visit the GENESIS product page to learn more or contact an industrial automation expert to discuss your project or request a personalized demo.

English

English

Czech

Czech

German

German

French

French

Italian

Italian

Japanese

Japanese

Polish

Polish