Category: Sustainability

Fraicheur de Paris

Paris, France

Category: Sustainability

Paris, France

“GENESIS64 was the right choice for us as the software provided the needed connectivity and was both robust and flexible so could be easily configured by our teams. As a Gold Partner with Microsoft, the software also provided guaranteed compatibility with the Microsoft tools we wanted to implement.”

In 1991, the City of Paris awarded CLIMESPACE, a wholly owned subsidiary of ENGIE Group (a French multinational utility company), a 20-year contract to operate and develop its cooling system. However, in April 2022, Fraîcheur de Paris replaced CLIMESPACE as the operator of the district’s cooling network, which is currently one of the largest in the world. Fraîcheur de Paris is co-owned by the ENGIE Group (85%) and Régie autonome des transports parisiens or RATP (15%) and will be responsible for the production, storage, transport, and distribution of the city’s cooling energy for the next 20 years. Integrated into the city’s architecture and completely out of sight, the system meets the cooling requirements of hotels, department stores, offices state buildings, museums, and theatres throughout the city. Moreover, since the cooling network is operated in Paris, it can be cooled by water from the Seine River, thus cooling the city in the summer months while simultaneously improving energy efficiency and reducing CO₂ emissions.

The cooling system involves 153 employees, 10 production sites, and 4 energy storage sites. Approximately 765 customers are connected, representing about 6 million square meters of air conditioning. It utilizes 92 kilometers of underground networking and supplies 490 GWh per year of cooling energy, generating 90 million Euros in revenue. By the end of the contract with the City of Paris in 2042, Fraîcheur de Paris ambitiously plans for the network to cover all the capital’s arrondissements, which will include tripling its length with an additional 158 kilometers and adding 20 new production plants and 10 new storage facilities, to supply cooling to over 3,000 customers. The previous cooling system primarily covered service-sector buildings. However, in the future, the new network will extend to an additional 300 buildings, dedicated to new customers sensitive to high temperature such as hospitals, childcare centers, retirement homes, as well as small businesses.

“GENESIS64 was the right choice for us as the software provided the needed connectivity and was both robust and flexible so could be easily configured by our teams. As a Gold Partner with Microsoft, the software also provided guaranteed compatibility with the Microsoft tools we wanted to implement.”

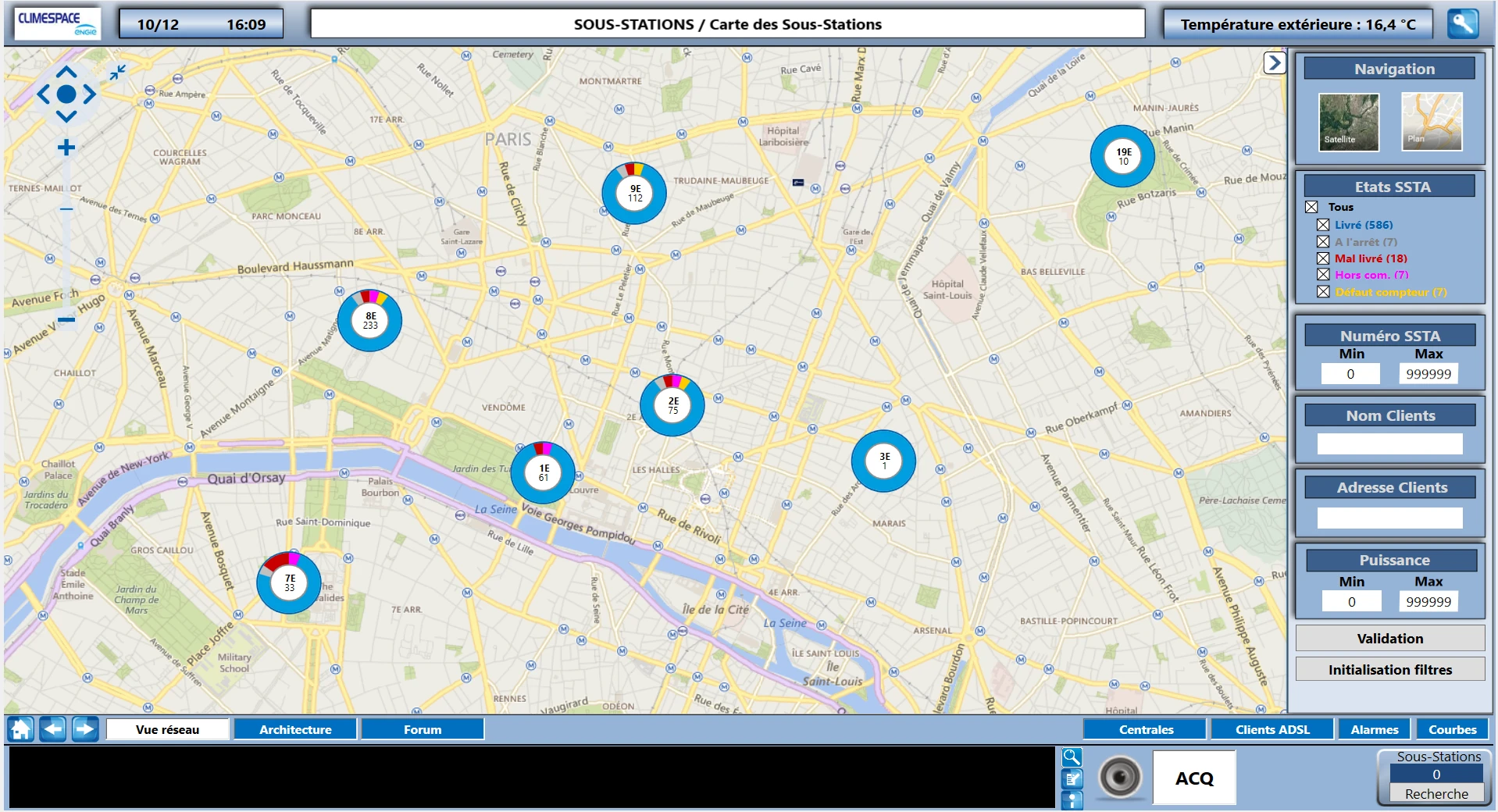

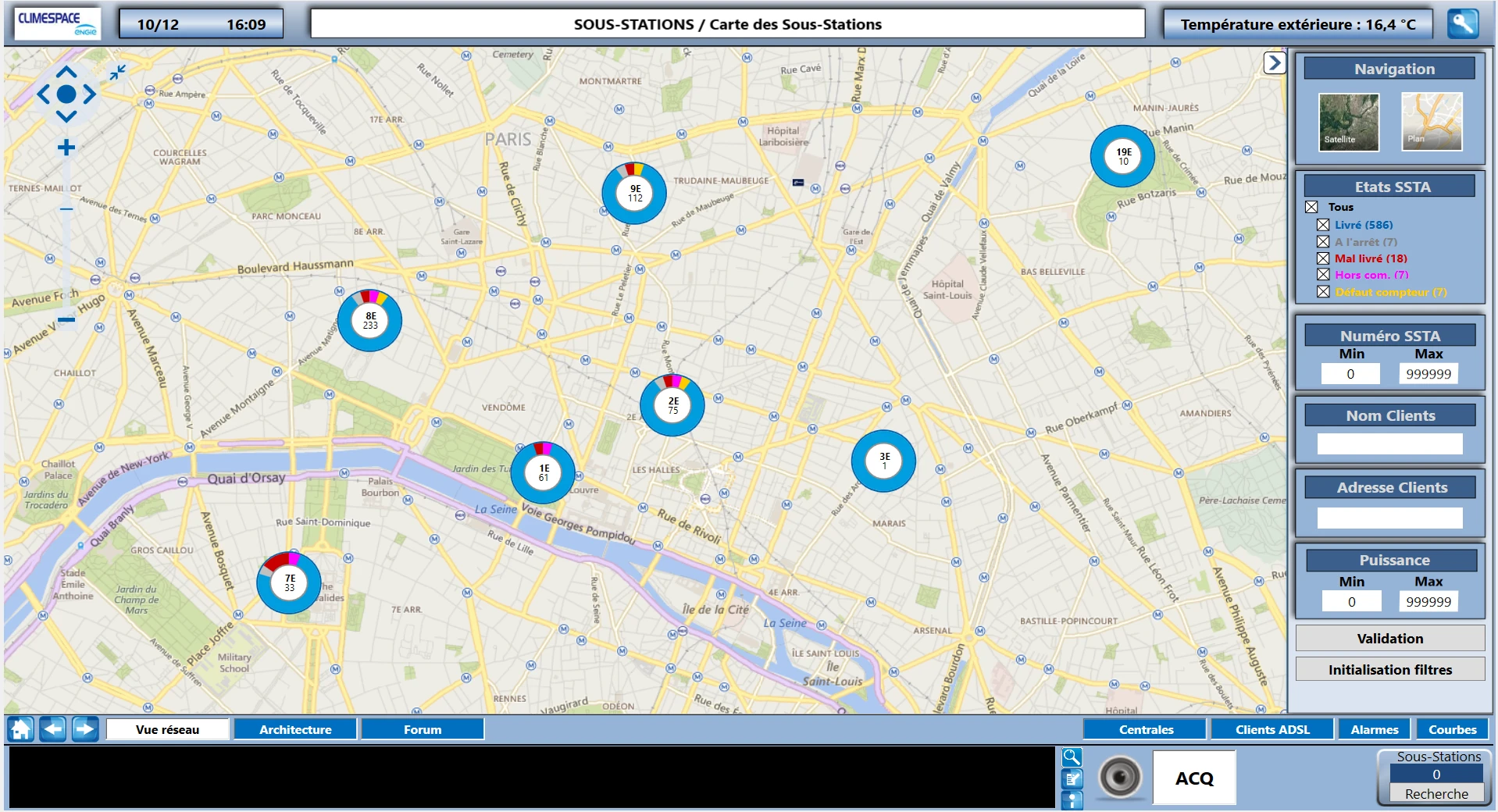

Real-time status in map view of Paris cooling stations provided via GENESIS64

Real-time status in map view of Paris cooling stations provided via GENESIS64

Fraîcheur de Paris sought a new HMI/SCADA solution to replace the existing obsolete control system. The company also wanted the new SCADA system to provide additional functionality over the previous system, including web connectivity, improved database handling, and data mining/ collection tools. Additionally, the company required real-time monitoring of all its production plants and stations as it is responsible for ensuring 24/7 production and delivery of cooling to its many customers. The responsibilities of its operations teams include controlling the cooling distribution network using specific software, responding to requests from end customers via a call center, and checking and identifying potential problems on the distribution network. To implement the project, Fraîcheur de Paris chose ACTEMIUM as the system integrator. With its headquarters in France and its established expertise and experience, ACTEMIUM was well suited for the project. The company has a global network of experts dedicated to industrial processes to deliver a range of safe and sustainable solutions and services across the industrial lifecycle. Its mission is to help clients improve their competitive advantage and industrial performance. After evaluating several SCADA options during a yearlong benchmark process, GENESIS64 was selected, as it was considered the solution that seemed the most suited to the needs of Fraîcheur de Paris.

Real-time status in map view of Paris cooling stations provided via GENESIS64

Real-time status in map view of Paris cooling stations provided via GENESIS64

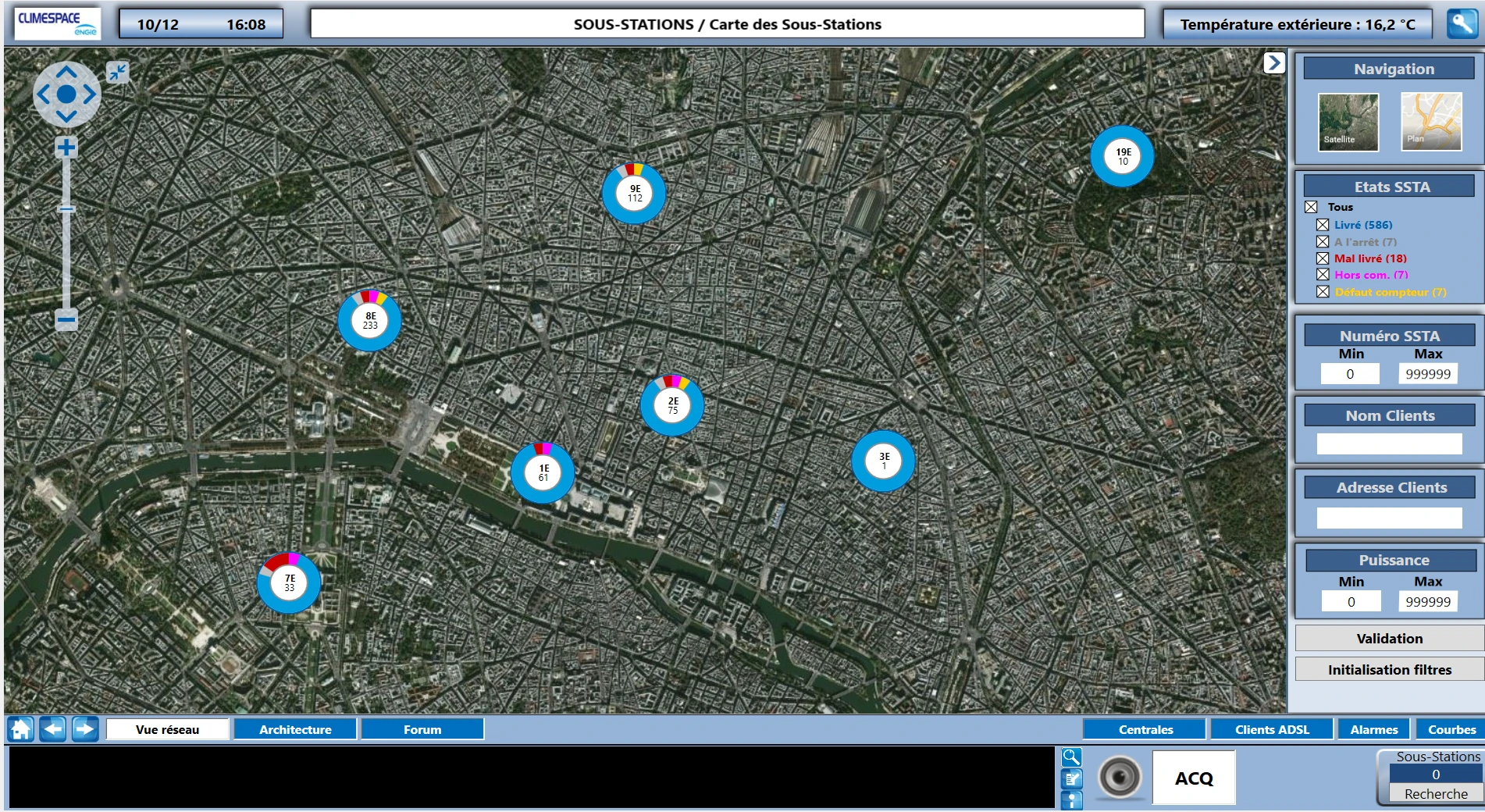

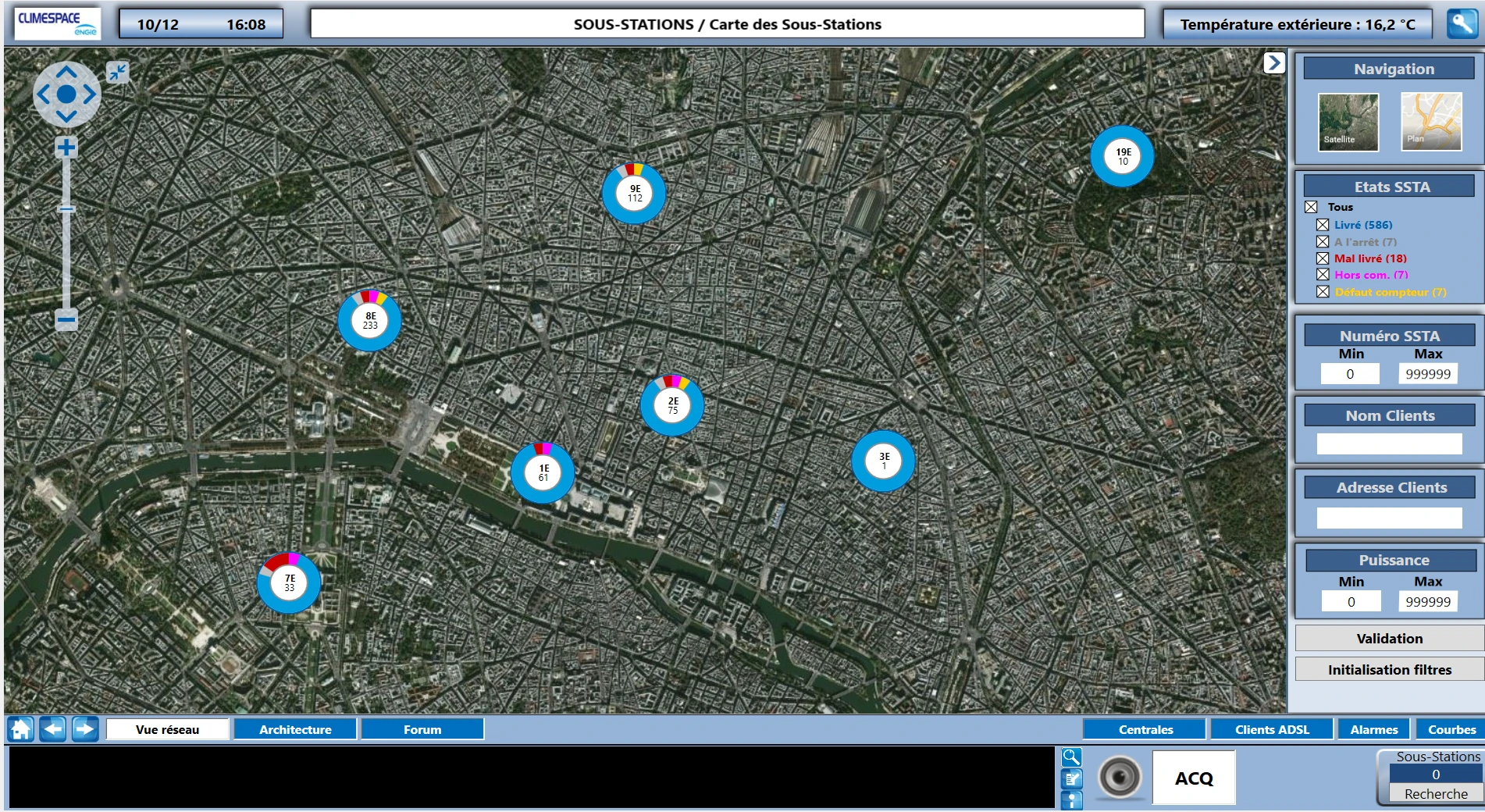

GENESIS64-produced display providing satellite image of Paris cooling network with live KPIs

GENESIS64-produced display providing satellite image of Paris cooling network with live KPIs

GENESIS64-produced display providing satellite image of Paris cooling network with live KPIs

GENESIS64-produced display providing satellite image of Paris cooling network with live KPIs

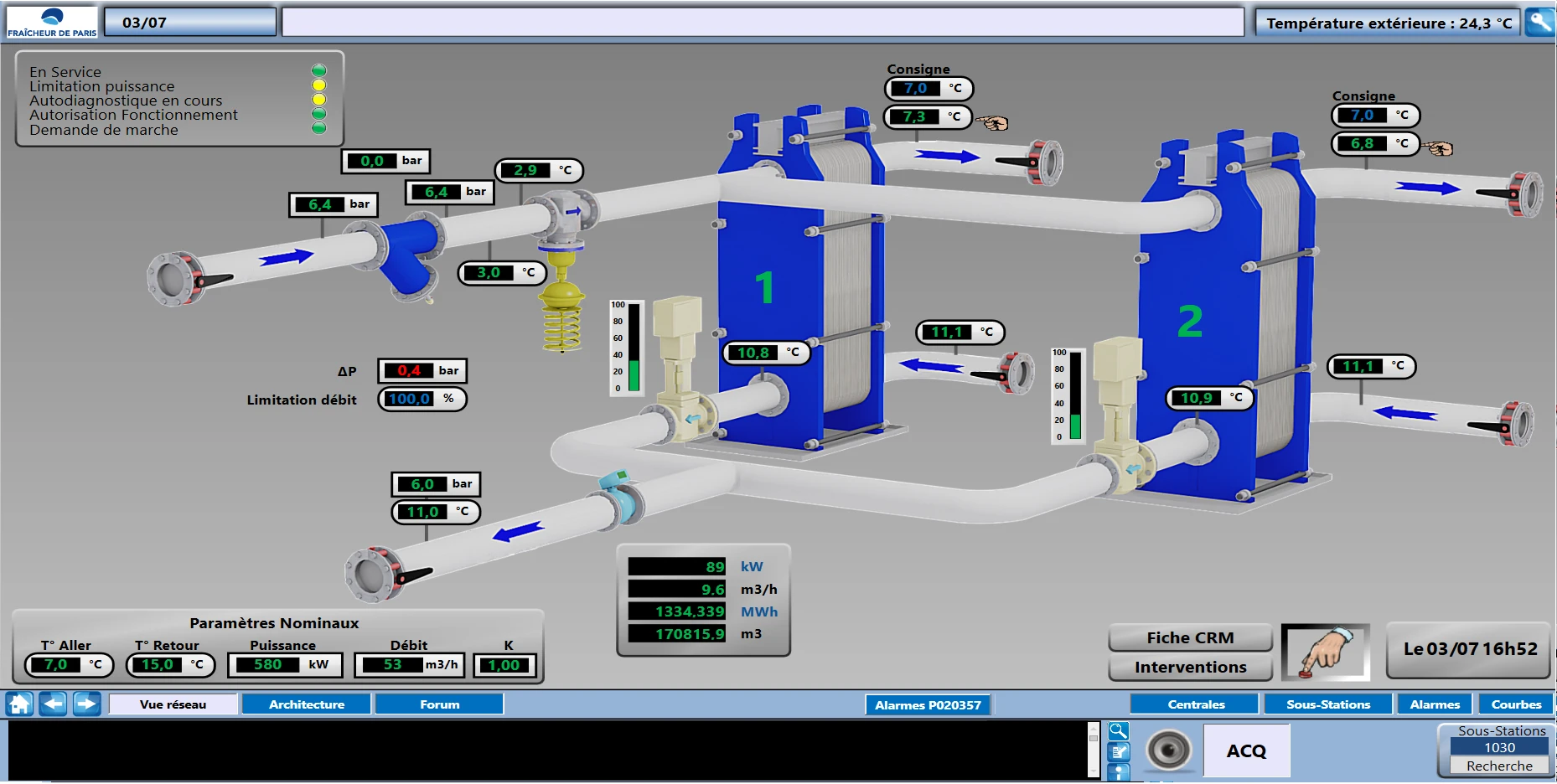

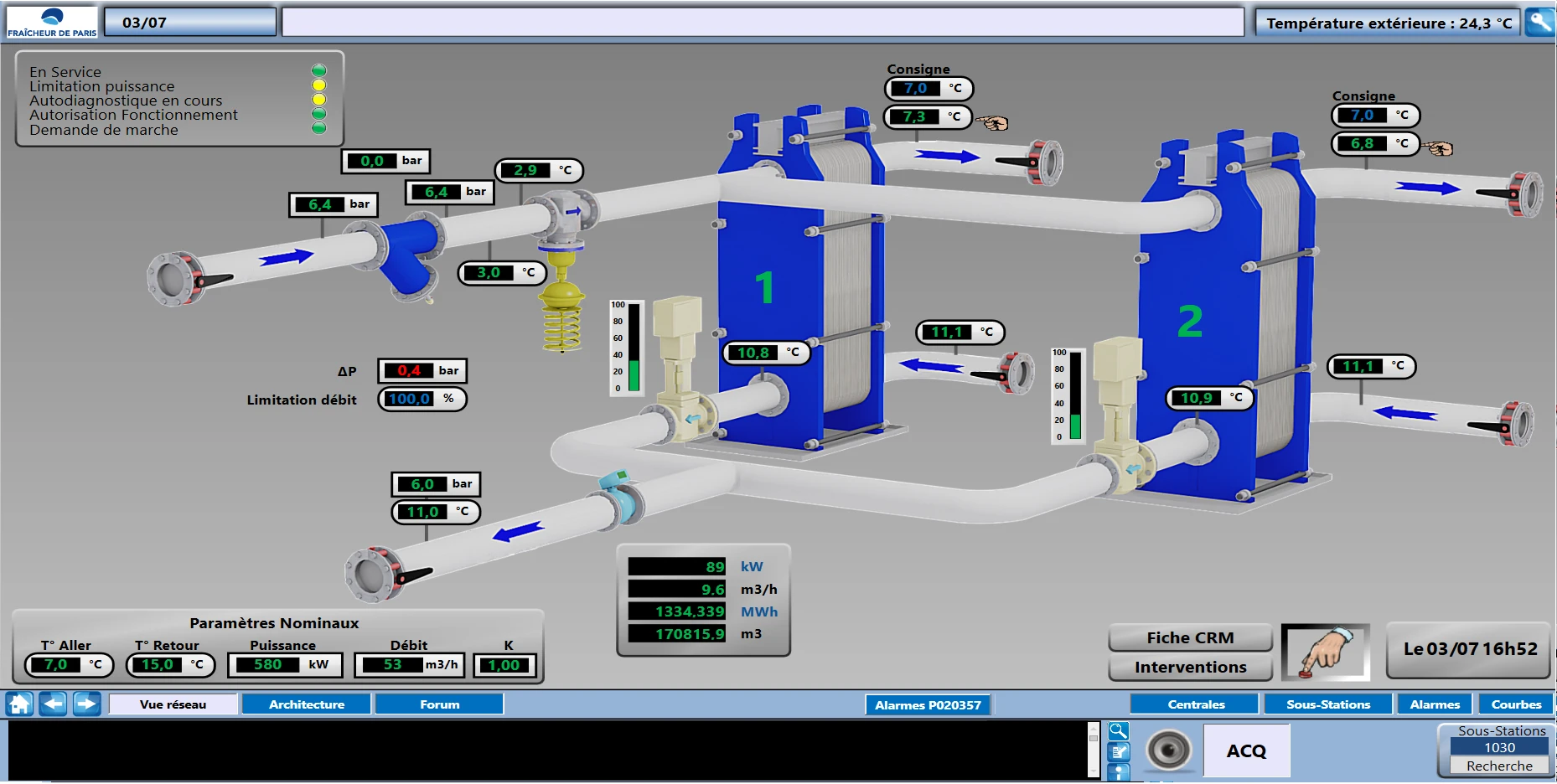

3D equipment status enabled through GENESIS64

3D equipment status enabled through GENESIS64

GENESIS64 was able to meet Fraîcheur de Paris’ requirement for an autonomous HMI/SCADA development platform that could make changes in real time, as well as be more easily deployed at new sites via a configurator. The new system now plays an integral role in the supervision of cooling supply to 765 customers, the management of real-time and historical alarms, command and control of multiple substations, and the logging of years of operational data for the purpose of report generation. GENESIS64 provides the required audit trail with secure user access control, plus connectivity with third-party applications. It also supports multi-screen visualization and delivers a high-level of system availability.

3D equipment status enabled through GENESIS64

3D equipment status enabled through GENESIS64

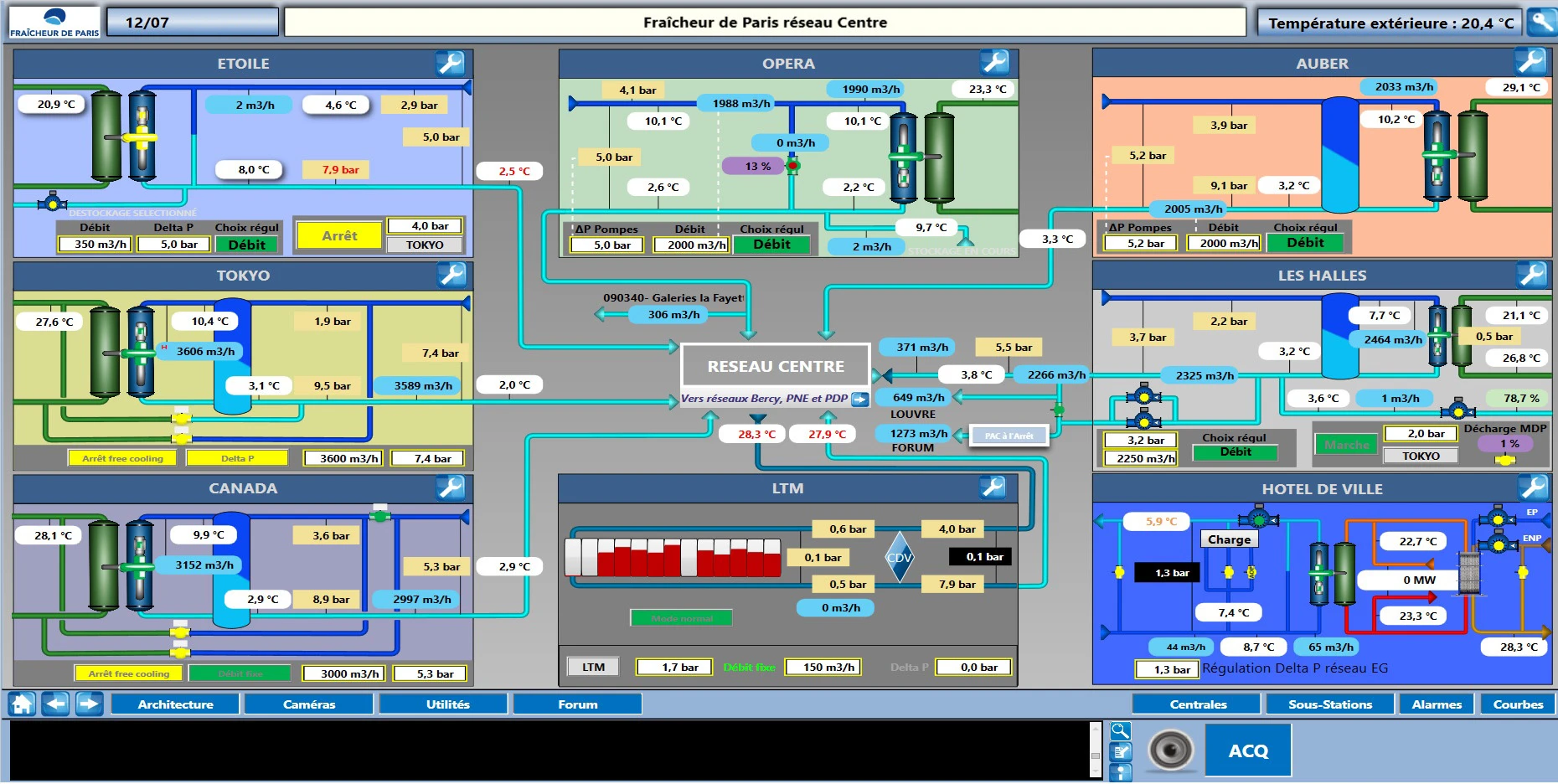

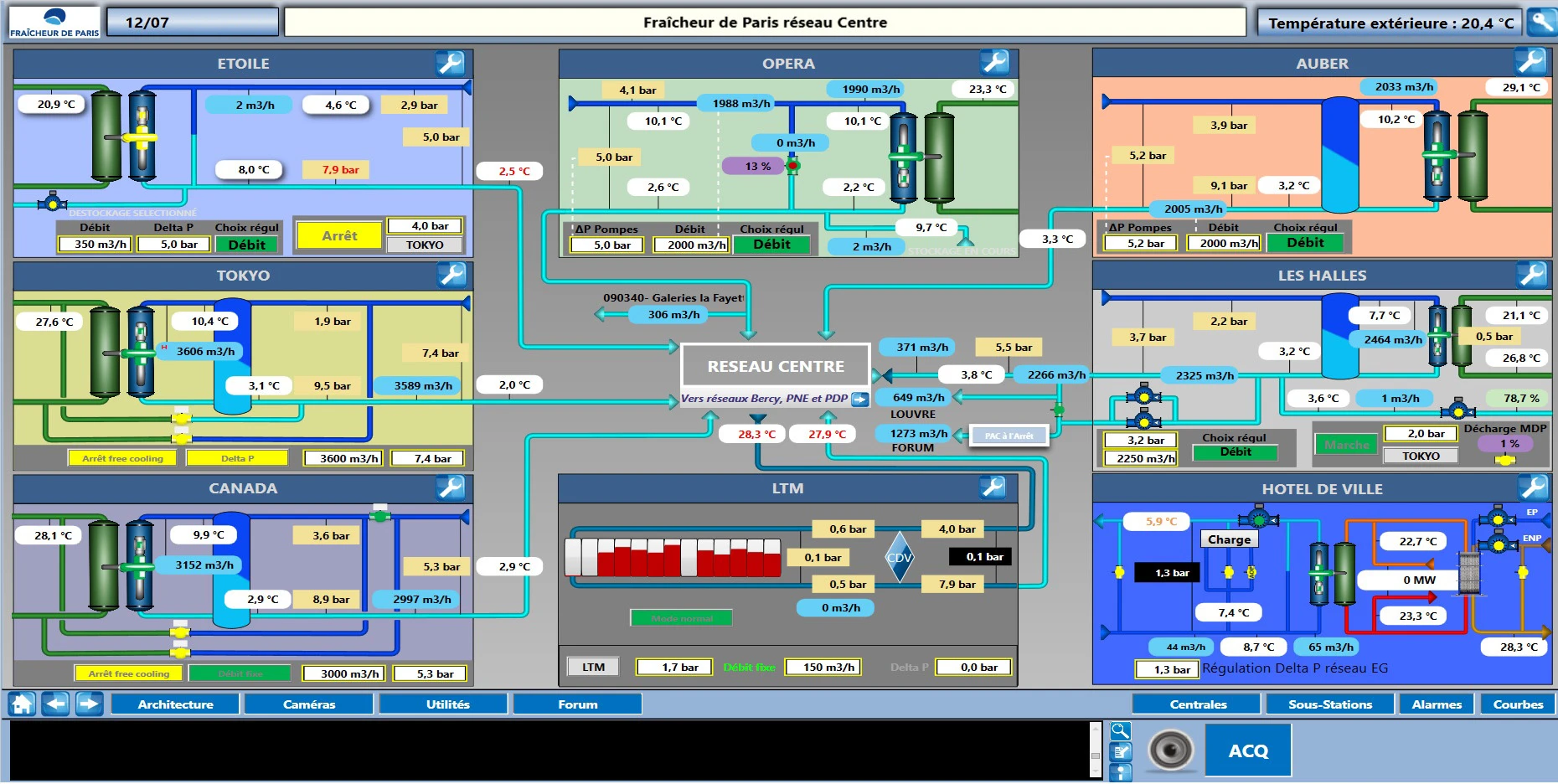

Network center dashboard

Network center dashboard

Thanks to GENESIS64, Fraîcheur de Paris continues to deliver cooling to its Paris customers. Another great advantage to using the software was being able to contact the ICONICS France team when needed thus adding to deployment efficiency and to quick resolution of issues. The support and availability of the ICONICS teams for Fraîcheur de Paris’ system development projects was a significant asset for the integration of GENESIS64 and Hyper Historian into their system.

Network center dashboard

Network center dashboard