Category: Manufacturing

SÖKTAŞ Intelligent Textile Manufacturing

Soke, Turkey

Category: Manufacturing

Soke, Turkey

“Working with ÇOLBAN and Mitsubishi Electric Iconics Digital Solutions was instrumental in the successful completion of our project. Their support made it significantly easier to overcome the challenges we encountered during the process. By using GENESIS64, we have established a solid infrastructure that we believe will serve as a strong foundation for future planned projects. I would like to thank everyone who contributed to this achievement.”

Founded in 1971 and headquartered in Soke, Turkey, along the Meander River, SÖKTAŞ creates specialty textiles for the fabric industry. From seasonal concepts to bespoke collections that suit today’s contemporary lifestyles, the company sustainably produces fabrics that provide “high-quality, artisanal, and technologically advanced fabrics” to the apparel and fashion sectors.

The company has over a hundred years of expertise in cotton farming and more than fifty years of commitment to innovative fabric development and textile production. Their experience and unique perspective allow them to manage the entire production chain from cotton cultivation to fabric production. SÖKTAŞ is proud of their Meander Valley heritage and of their contribution to the design and history of the fabric industry.

“Working with ÇOLBAN and Mitsubishi Electric Iconics Digital Solutions was instrumental in the successful completion of our project. Their support made it significantly easier to overcome the challenges we encountered during the process. By using GENESIS64, we have established a solid infrastructure that we believe will serve as a strong foundation for future planned projects. I would like to thank everyone who contributed to this achievement.”

Operations Overview

Operations Overview

Before the project, SÖKTAŞ operated outdated separate and independent systems to monitor water usage and heat recovery exchangers in their production processes. These systems were entirely disconnected, making centralized monitoring impossible and reporting highly inefficient.

For example, the legacy system consisted of two PCs and disparate software, which made it challenging to adapt or modify interfaces. Reports had to be generated manually, consuming valuable time and increasing the likelihood of human error. As water and heat exchangers are critical components in textile manufacturing for optimizing energy consumption and maintaining product quality, the company needed a modern system capable of real-time monitoring and automation. SÖKTAŞ therefore required a unified and integrated system that could be monitored from a single point, offer a standard reporting structure, and provide scalability for future enhancements and modifications.

In particular, the company needed to monitor and control these key metrics:

SÖKTAŞ selected ÇOLBAN Elektrik Otomasyo as their system integrator (SI) due to their extensive expertise in SCADA systems and in-depth knowledge of Mitsubishi Electric products which they use. ÇOLBAN Elektrik Otomasyon also has extensive experience developing projects with various SCADA brands, giving them a deep understanding of the advantages and disadvantages of alternative products. Another key factor in the decision was ÇOLBAN’s proven track record with SÖKTAŞ, having successfully completed previous projects such as the wastewater treatment system revision and upgrades to existing machinery using Mitsubishi Electric products. These successful collaborations, completed without any issues, highlighted ÇOLBAN’s reliability and technical proficiency—establishing a strong foundation of trust that made them the preferred choice for SÖKTAŞ on this project.

The GENESIS64 automation and digitalization software from Mitsubishi Electric Iconics Digital Solutions was chosen for its advanced features, flexibility, and the ability to integrate seamlessly into the solutions provided by ÇOLBAN. Their indepth research into the capabilities of the GENESIS software suite and how these products could be adapted to enhance their existing solutions was a key factor in their decision. Moreover, the capabilities of GENESIS64 aligned perfectly with the project’s specific needs, making it the ideal choice for delivering a comprehensive and scalable automation system.

Operations Overview

Operations Overview

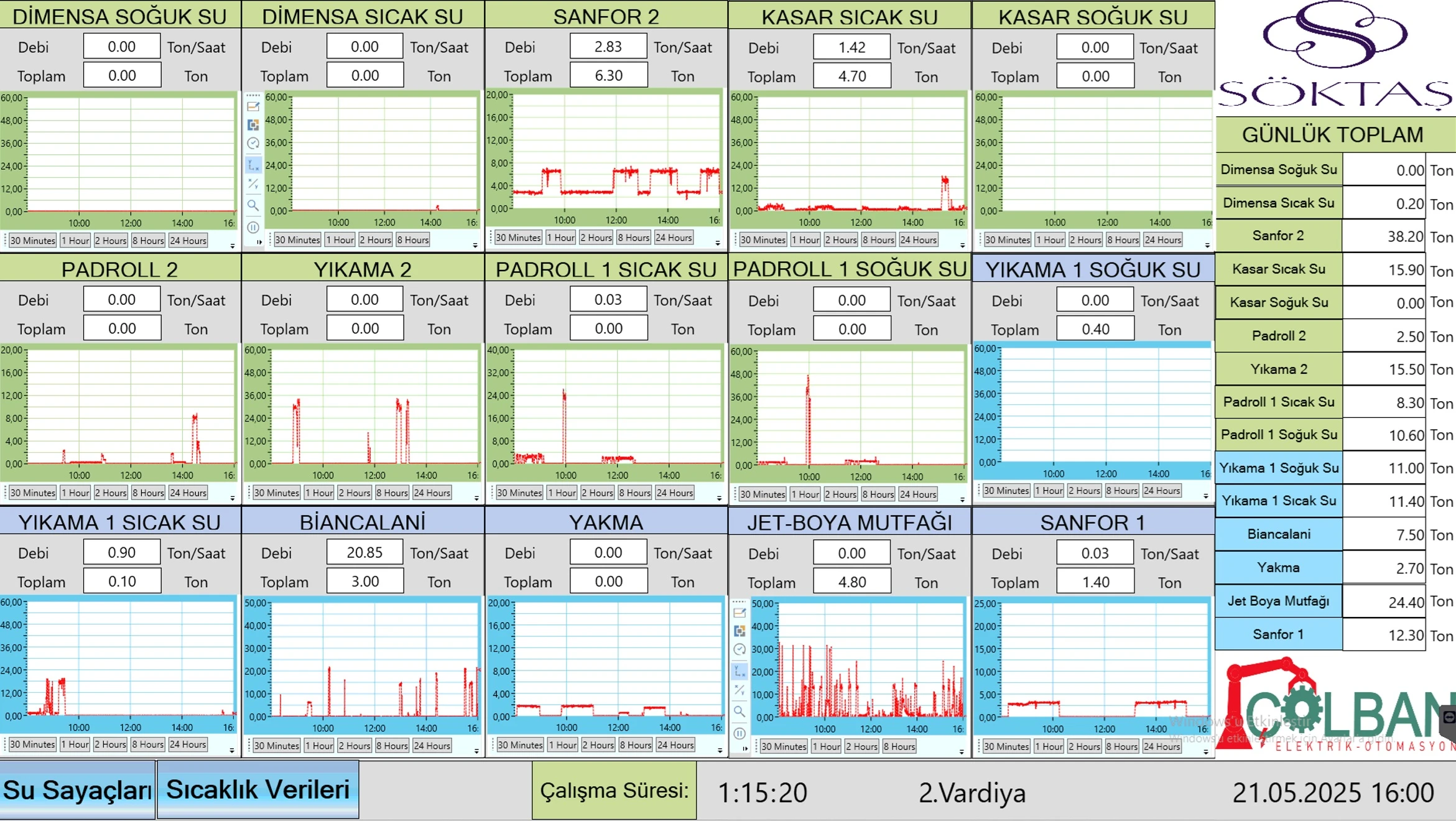

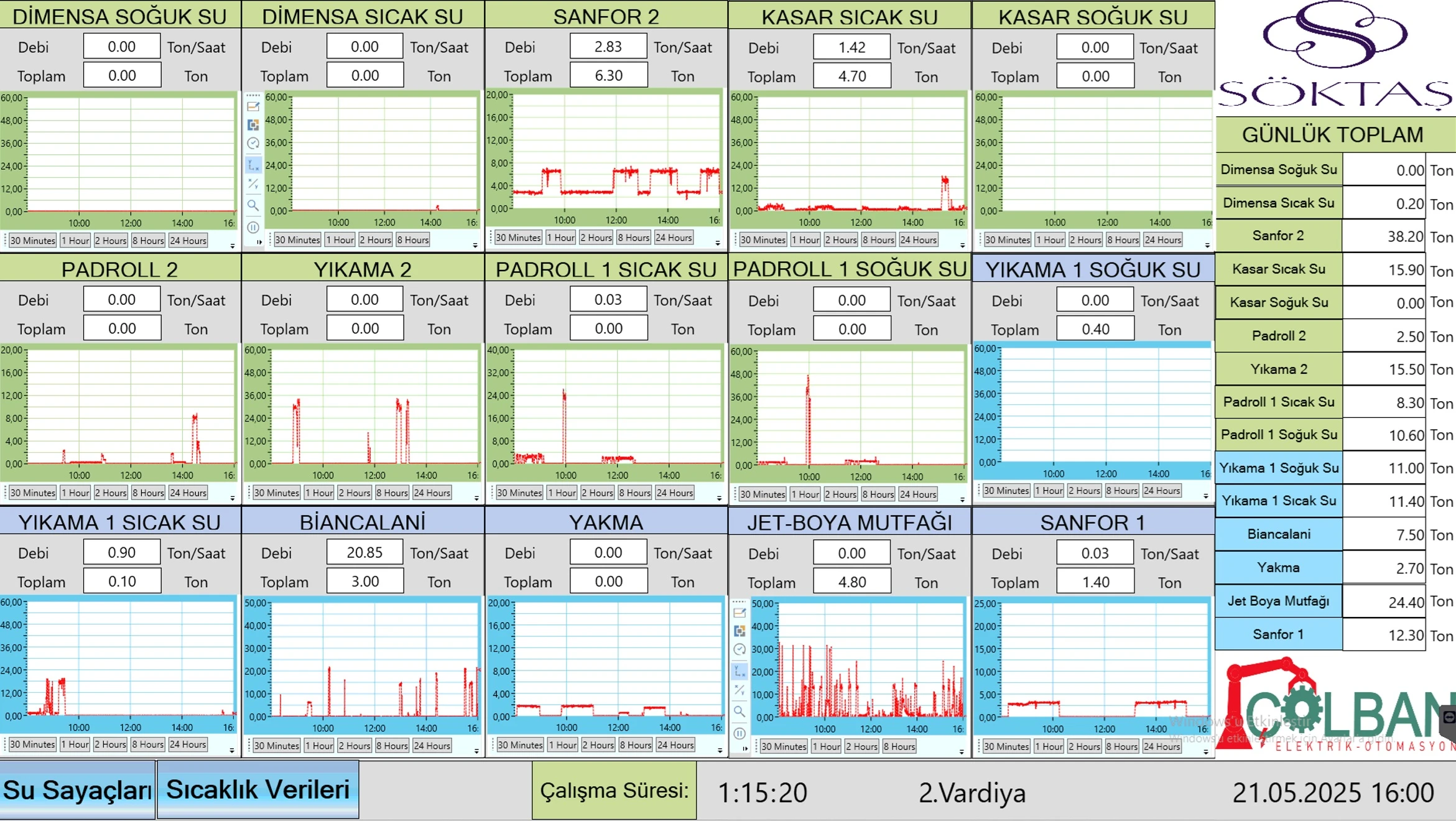

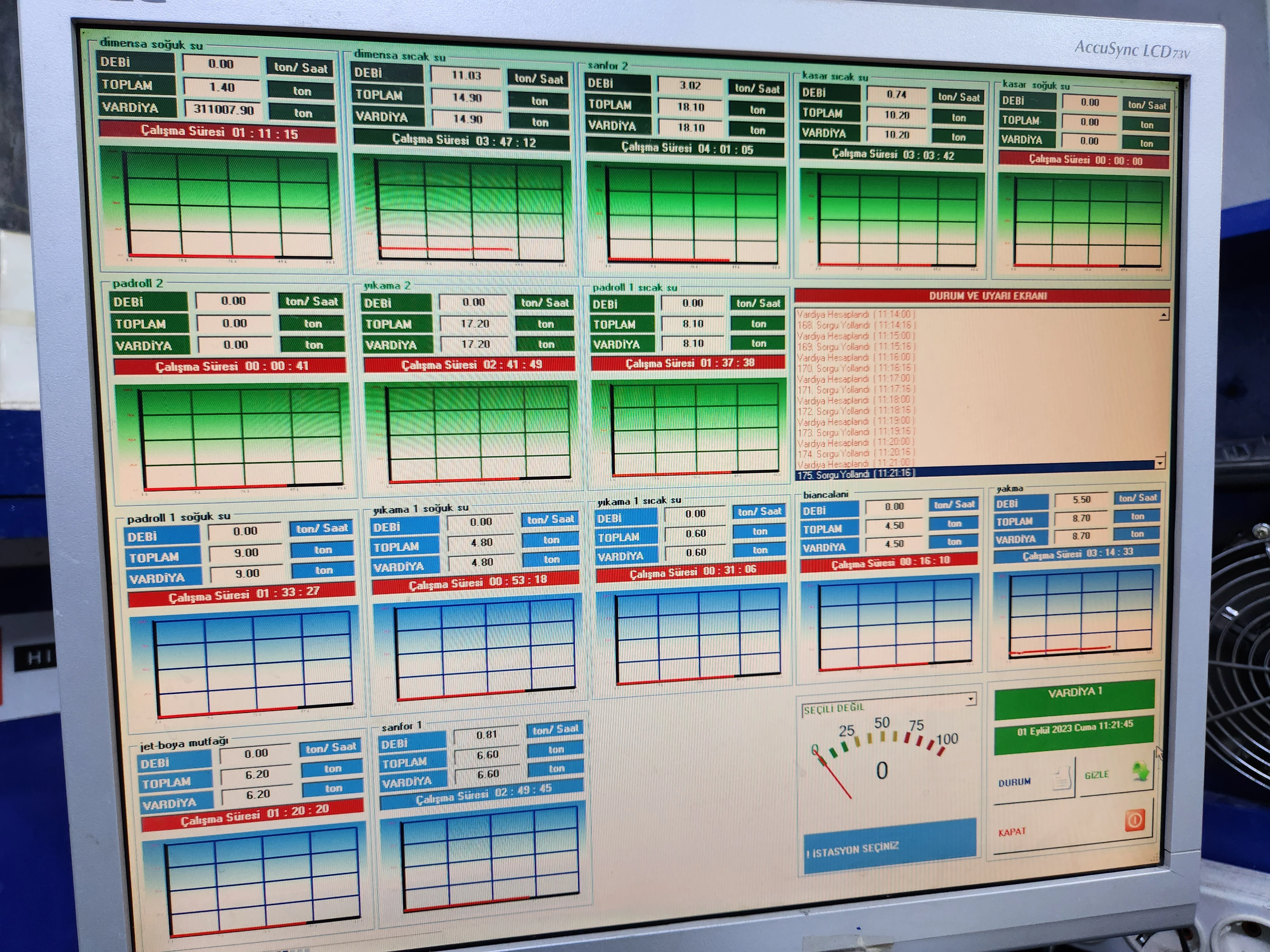

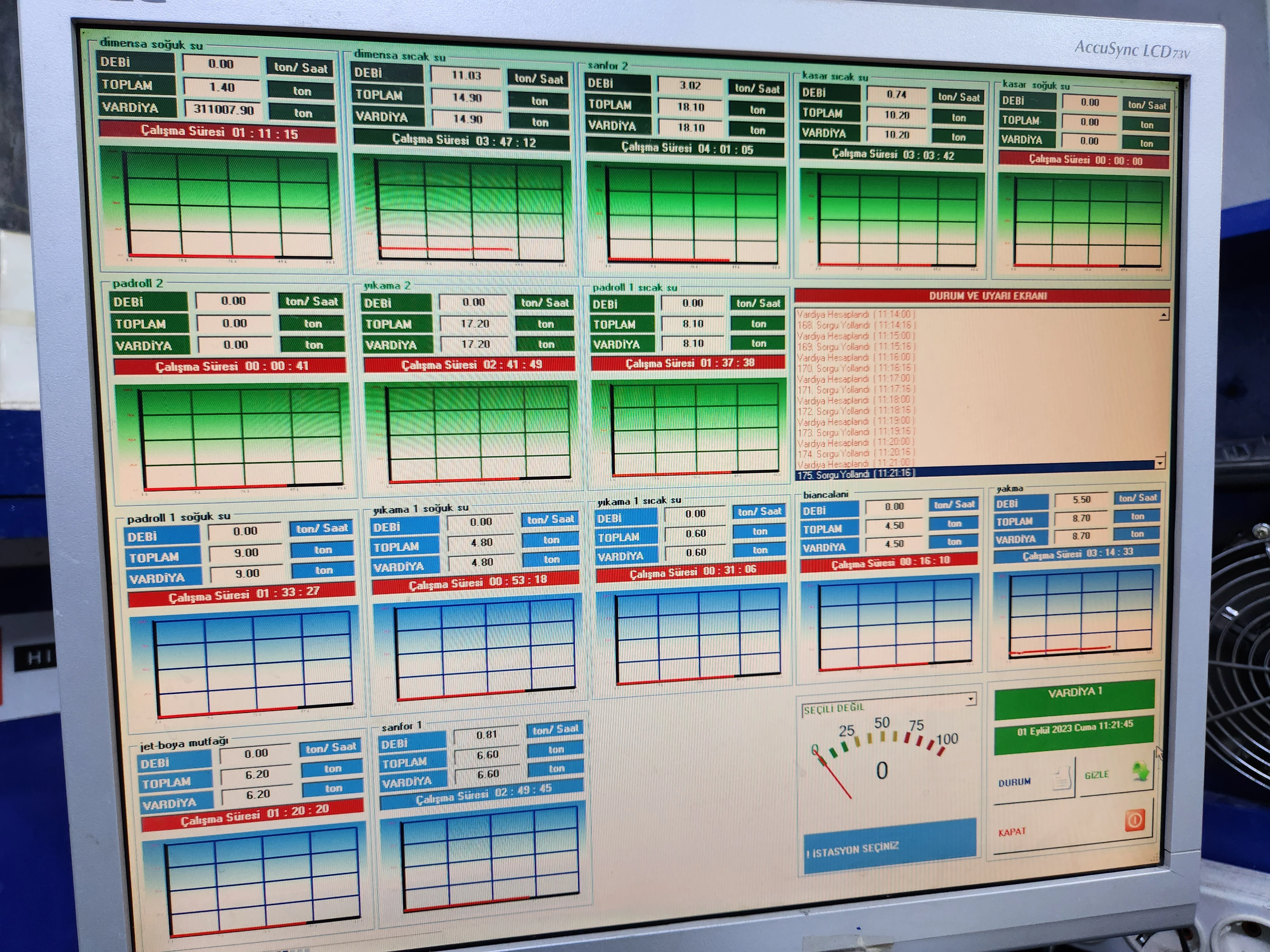

Data Visualization Dashboard

Data Visualization Dashboard

Leveraging over seven years of experience as a Mitsubishi Electric system integrator, ÇOLBAN delivered the complete automation solution for the SÖKTAŞ facility. The project made use of a wide range of Mitsubishi Electric products to ensure seamless integration, reliable performance, and long-term scalability.

In this project, the following products were deployed:

The combination of Mitsubishi Electric Iconics Digital Solutions and equipment deliver a comprehensive and advanced automation deliver a comprehensive and advanced automation solution tailored to the unique needs of SÖKTAŞ.

Data Visualization Dashboard

Data Visualization Dashboard

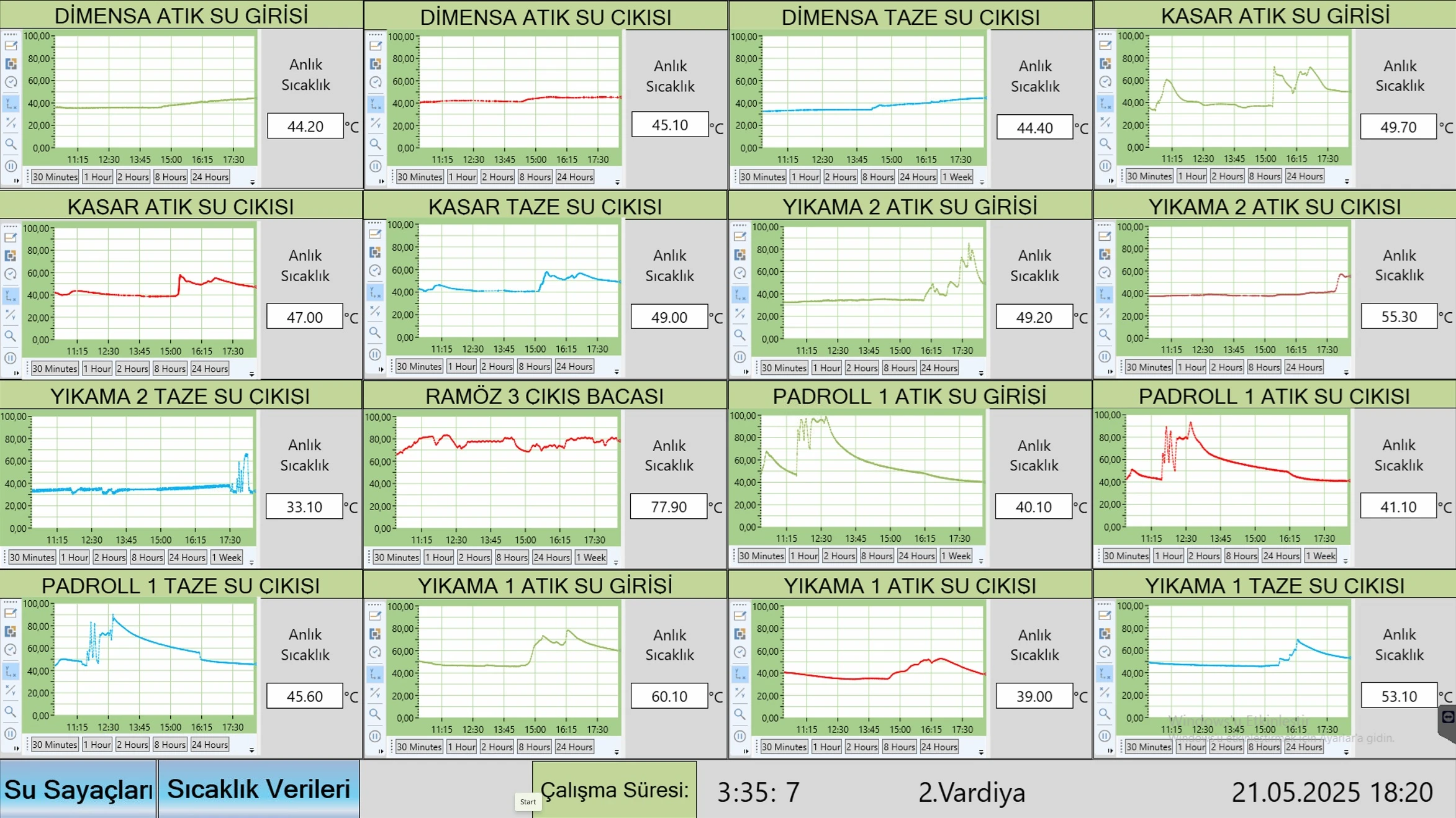

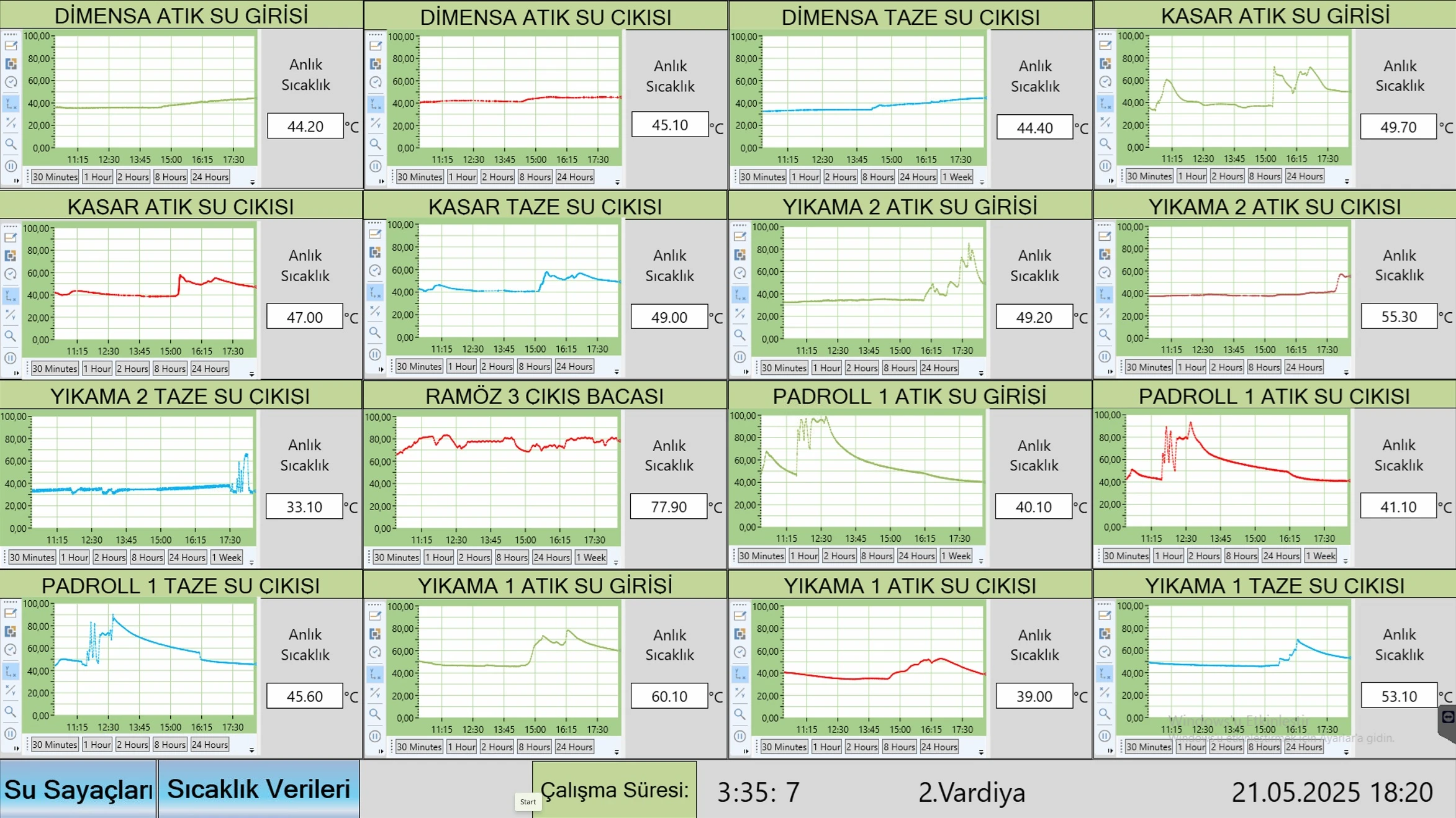

Main series dashboard

Main series dashboard

The deployment of the GENESIS64 automation and digitalization platform brought several significant improvements over the legacy system:

These advancements have significantly improved operational efficiency while enhancing the accuracy and reliability of monitoring and reporting at SÖKTAŞ.

Additionally, collaborating with Mitsubishi Electric Iconics Digital Solutions proved seamless and efficient, thanks to GENESIS64’s intuitive interface, clarity, and flexibility—all of which supported smooth and rapid implementation. The platform not only met SÖKTAŞ’s immediate requirements but also provided the adaptability needed for future enhancements.

This positive experience strengthened SÖKTAŞ’s confidence in the solution, allowing the company to focus on optimizing operations and driving long-term process improvements.

Main series dashboard

Main series dashboard

For SÖKTAŞ, working with Mitsubishi Electric Iconics Digital Solutions represents a step toward embracing the future of industrial automation. Moreover, detailed briefings about the GENESIS software suite were provided, highlighting the cutting-edge technologies and advanced solutions that the platform offers. Through these insights, SÖKTAŞ gained a clear understanding of how GENESIS64 could address their current needs while preparing them for future challenges with innovative, high-tech solutions. This forward-looking approach aligns with SÖKTAŞ’s commitment to operational excellence and sustainability.

The new system is designed for scalability, with future plans to incorporate electric energy monitoring and machine operating hour tracking. These additional features are expected to enhance the system’s functionality further, providing deeper insights into energy consumption and machine efficiency.

SÖKTAŞ plans to implement this investment in the coming years as part of its broader strategic plan, aligning with the company’s long-term vision.