Category: Food and Beverage

Cyberlogic

Troy, Michigan, USA

Category: Food and Beverage

Troy, Michigan, USA

“Mitsubishi Electric Iconics Digital Solutions' ability to quickly collect, visualize, and report OPC data, and the mix of robust OPC clients was the reason we based our Enterprise Information System on GENESIS.”

Cyberlogic Technologies, Inc. is a leading independent supplier of industrial communication drivers and servers. Since 1992, the company has introduced many firsts, including the first 32-bit communication drivers for Windows platforms, first virtual drivers to migrate legacy applications to 32-bit operating systems and the first remote drivers to enable access to industrial networks from plant networks. Cyberlogic’s New Enterprise Information System for traceability is based on GENESIS visualization software and ReportWorX™.

“Mitsubishi Electric Iconics Digital Solutions' ability to quickly collect, visualize, and report OPC data, and the mix of robust OPC clients was the reason we based our Enterprise Information System on GENESIS.”

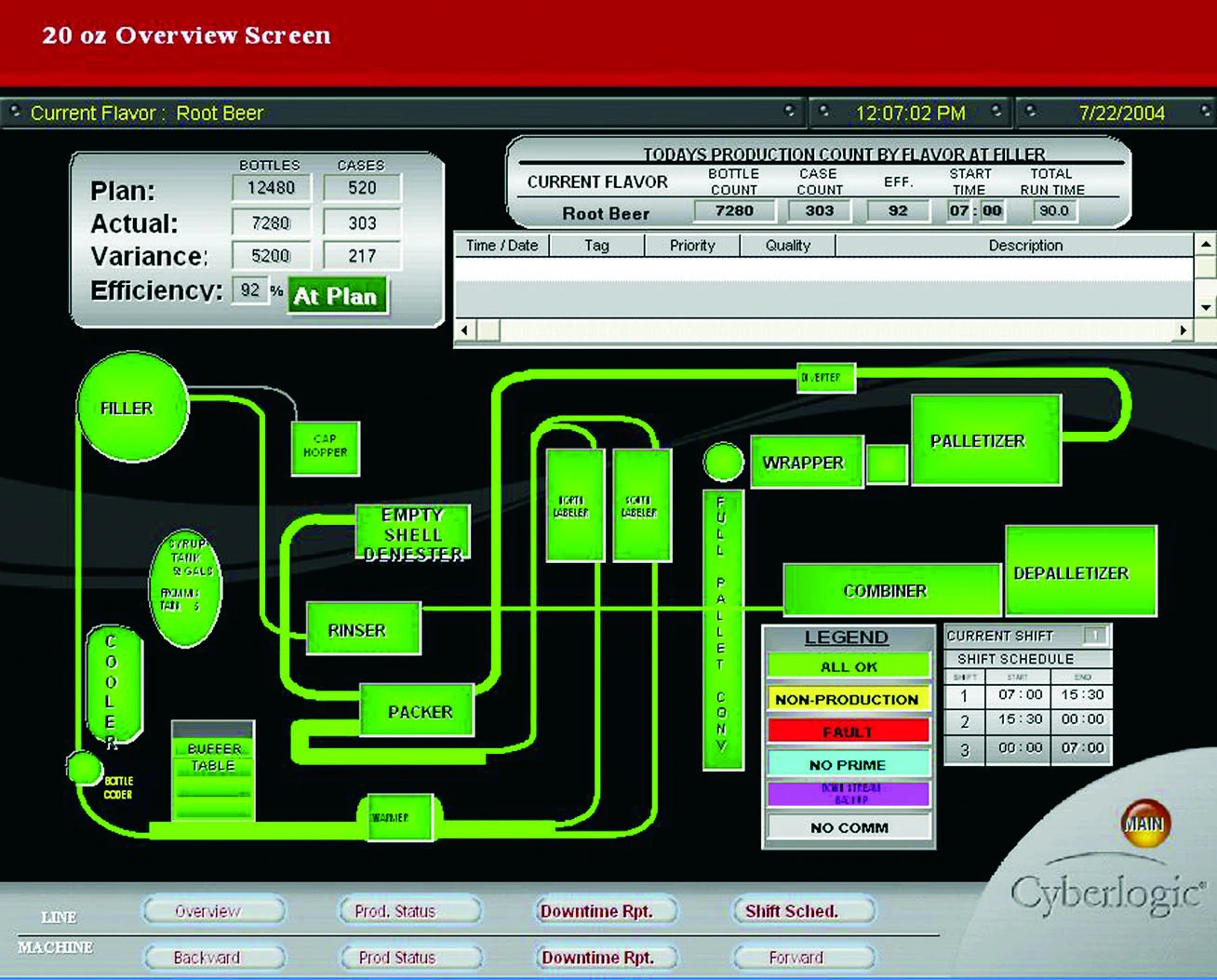

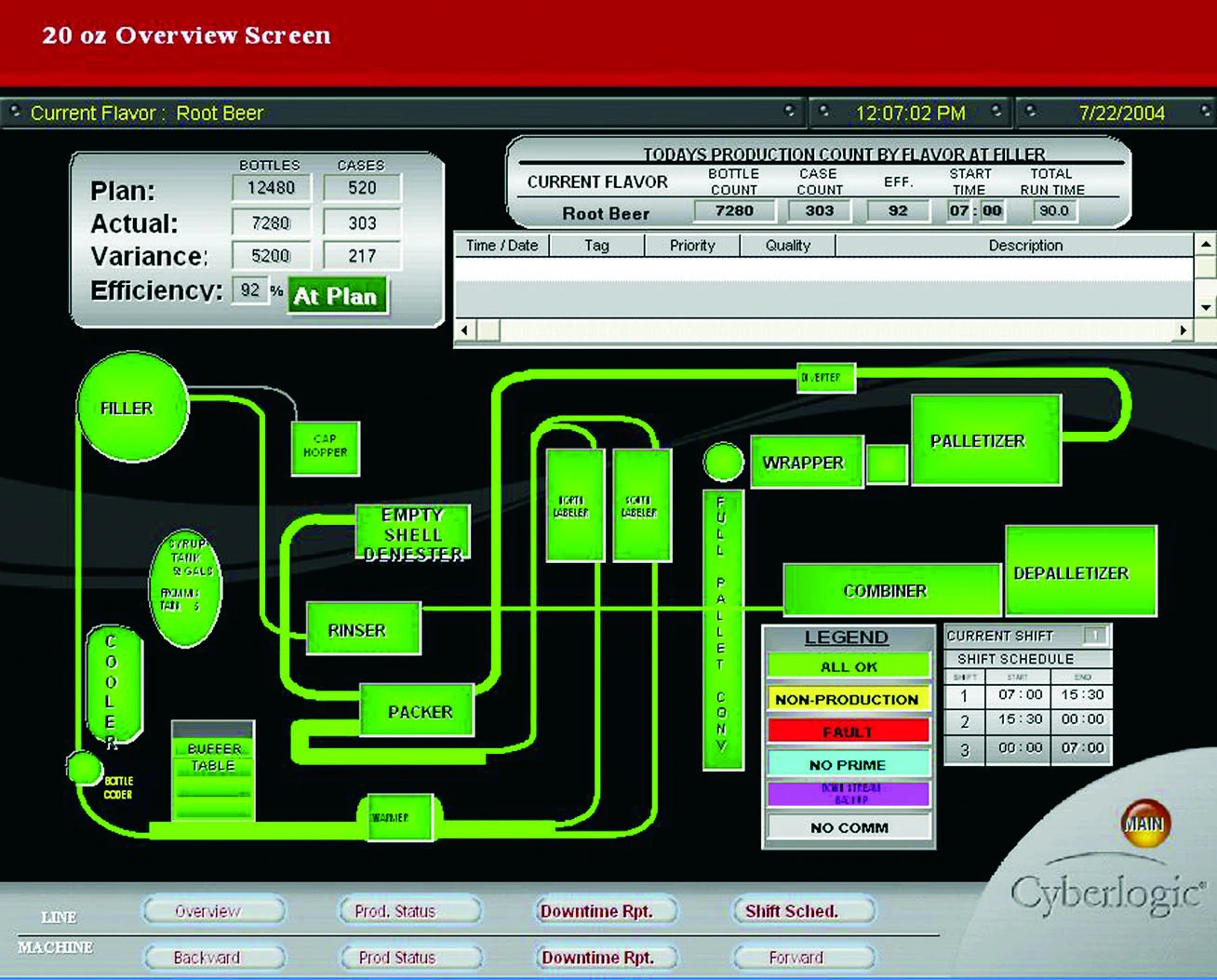

Bottling Process Monitoring Screen

Bottling Process Monitoring Screen

Cyberlogic’s Enterprise Information System is used to trace all source materials for a finished product and it is capable of mating the traceability information onto the outgoing products for use further down the supply chain. The system uses GraphWorX™, the visualization component for GENESIS, as the main interface into the system. ReportWorX™ is also used to provide production shift reports, downtime analysis and tractability reports. The Enterprise Information System includes a Web-based visualization interface that is based on WebHMI™.

Bottling Process Monitoring Screen

Bottling Process Monitoring Screen

A Cyberlogic Bottling Process Screen

A Cyberlogic Bottling Process Screen

The Enterprise Information System can be used in a wide range of applications. A recent deployment was for a large soft drink bottling company that needed traceability to track the ingredients to the original source. From a code stamped on the outside of the bottle one can quickly trace what batch of syrup was used and where the cap, bottle, and water came from. A report can then be generated that shows where other finished products that contain any of the source ingredients were shipped.

Being able to collect and report this information in real time can save thousands of dollars. In the event a recall is needed, the bottling company only needs to pull individual bottles instead of entire lots.

A Cyberlogic Bottling Process Screen

A Cyberlogic Bottling Process Screen

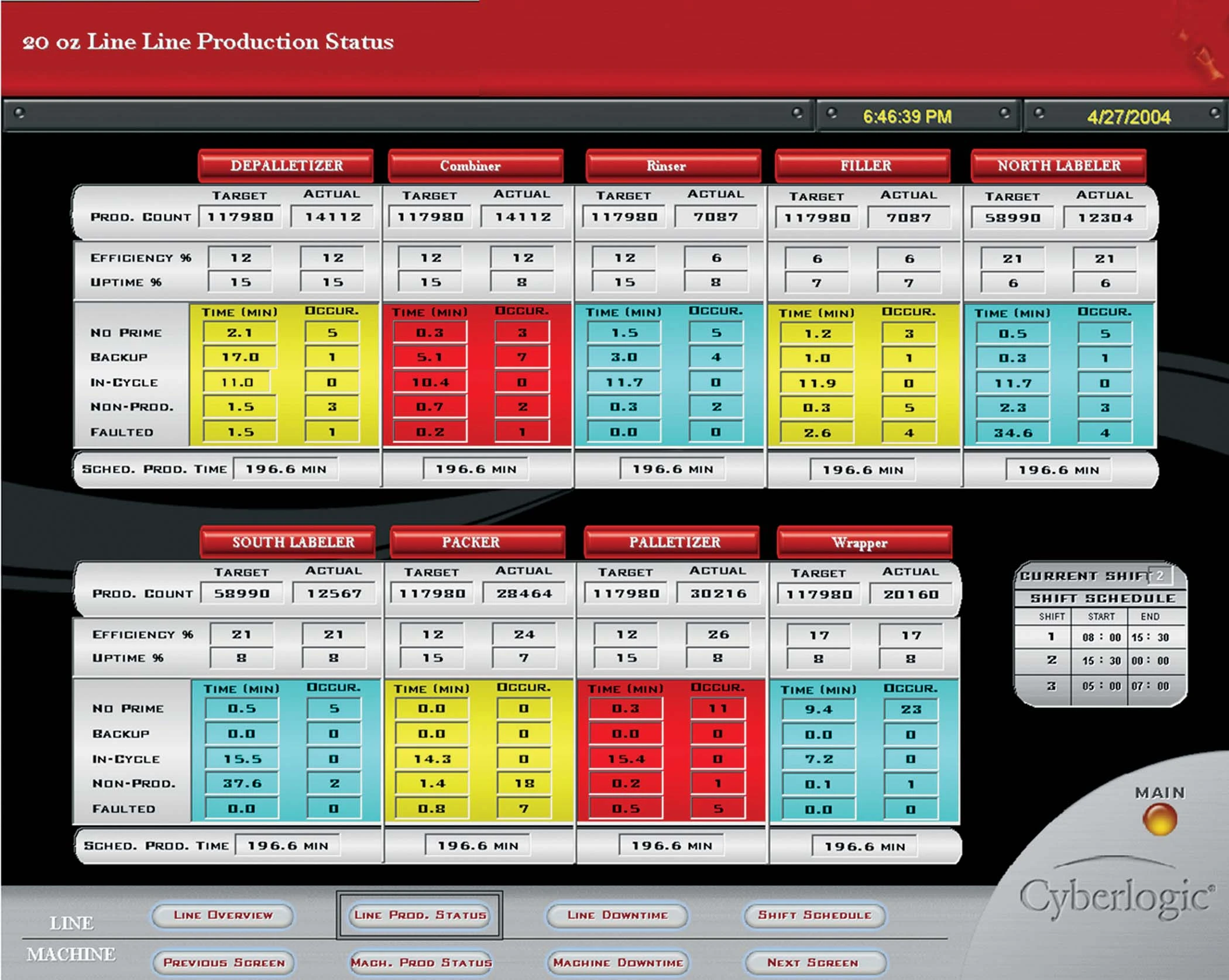

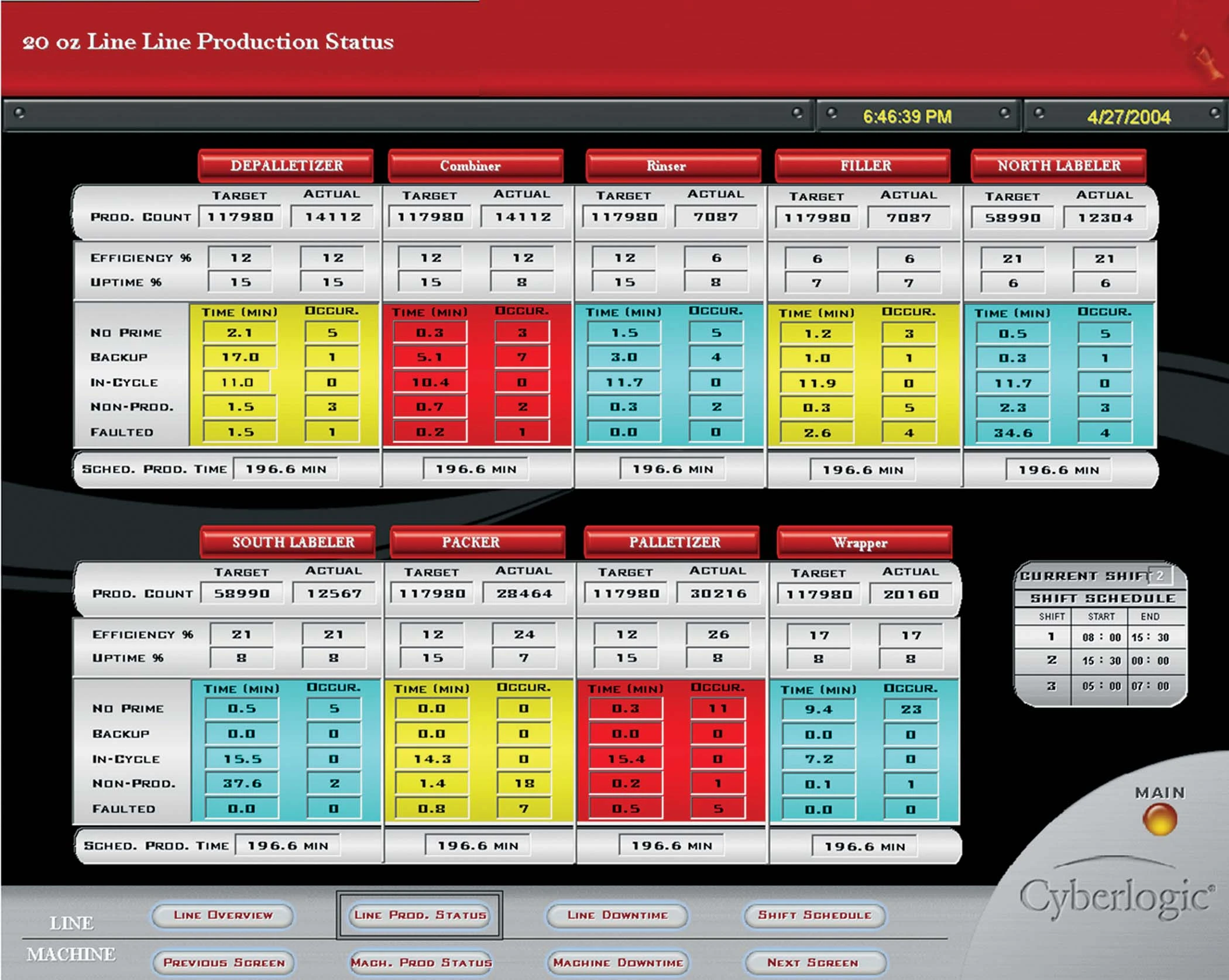

Production Status Screen

Production Status Screen

The Enterprise Information System runs on Microsoft Windows. Data is collected via OPC servers into GENESIS for visualization and analysis. The data repository is handled by a Microsoft SQL database that ReportWorX can data mine, GENESIS, SQL, and the OPC servers. OPC connectivity to the plant floor is provided via Cyberlogic’s OPC servers that are dynamically linked to the GENESIS system. Some key advantages to using the Cyberlogic OPC Servers in conjunction with OPC Clients from Mitsubishi Electric Iconics Digital Solutions include:

The Enterprise Information System that was recently deployed for a large soft drink bottling company was monitoring 4 lines with 10 PLCs per line for a total of over 2,500 I/O points. Allen Bradley SLC 500 PLC 2 and ControlLogix PLCs are used and the communication is via one universal, highly optimized, Cyberlogic DHX OPC Server. This OPC server contains all device drivers and no other software is needed to communicate with the Allen Bradley PLCs.

Production Status Screen

Production Status Screen

The main benefit for this system is that users can quickly identify products in the event of a recall. Instead of pulling entire shipments, users can quickly identify what lots or even what bottles need to be recalled.

We continue to work together with Cyberlogic to provide the best Enterprise Information System for traceability. Future projects include new components for the plant’s information system that will aid in advanced diagnostic and reporting.