Category: Manufacturing

SIGNATURE S.A.

Agnetz, France

Category: Manufacturing

Agnetz, France

Compagnie SIGNATURE, a 100 percent subsidiary of Burelle S.A., is the European leader in road signage and road marking. With more than 1,200 employees, Compagnie SIGNATURE has subsidiaries in Spain, Great Britain, Switzerland, Germany, Belgium, The Netherlands, Czech Republic, Romania, Greece and France.

France’s SIGNATURE S.A., with a network of 37 service points, contributes to the improvement of road safety and street comfort. As a complement to its design, manufacturing and installation activities, SIGNATURE proposes new services in the area of road asset management with the aim of guaranteeing the perpetuity of road marking facilities.

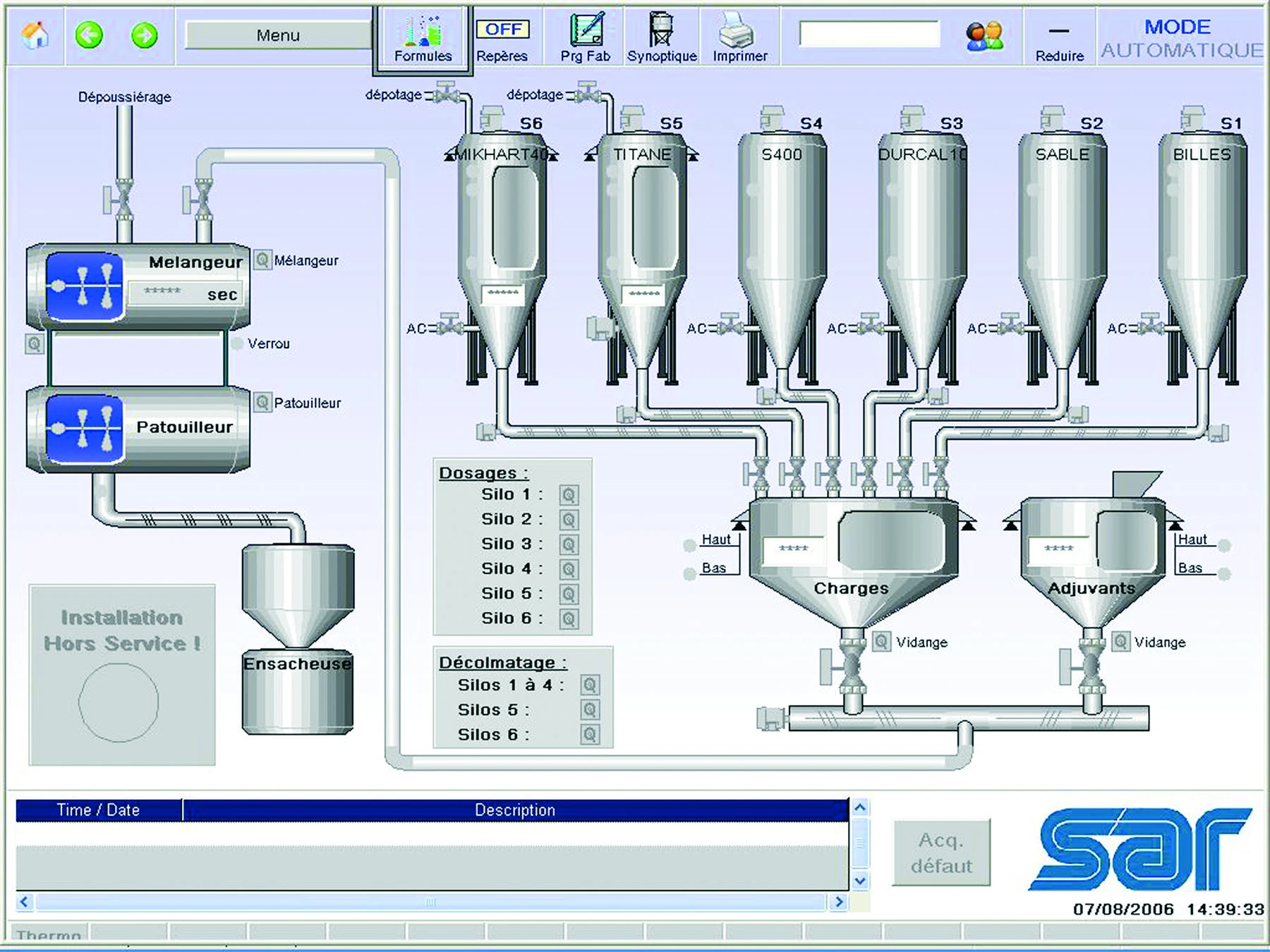

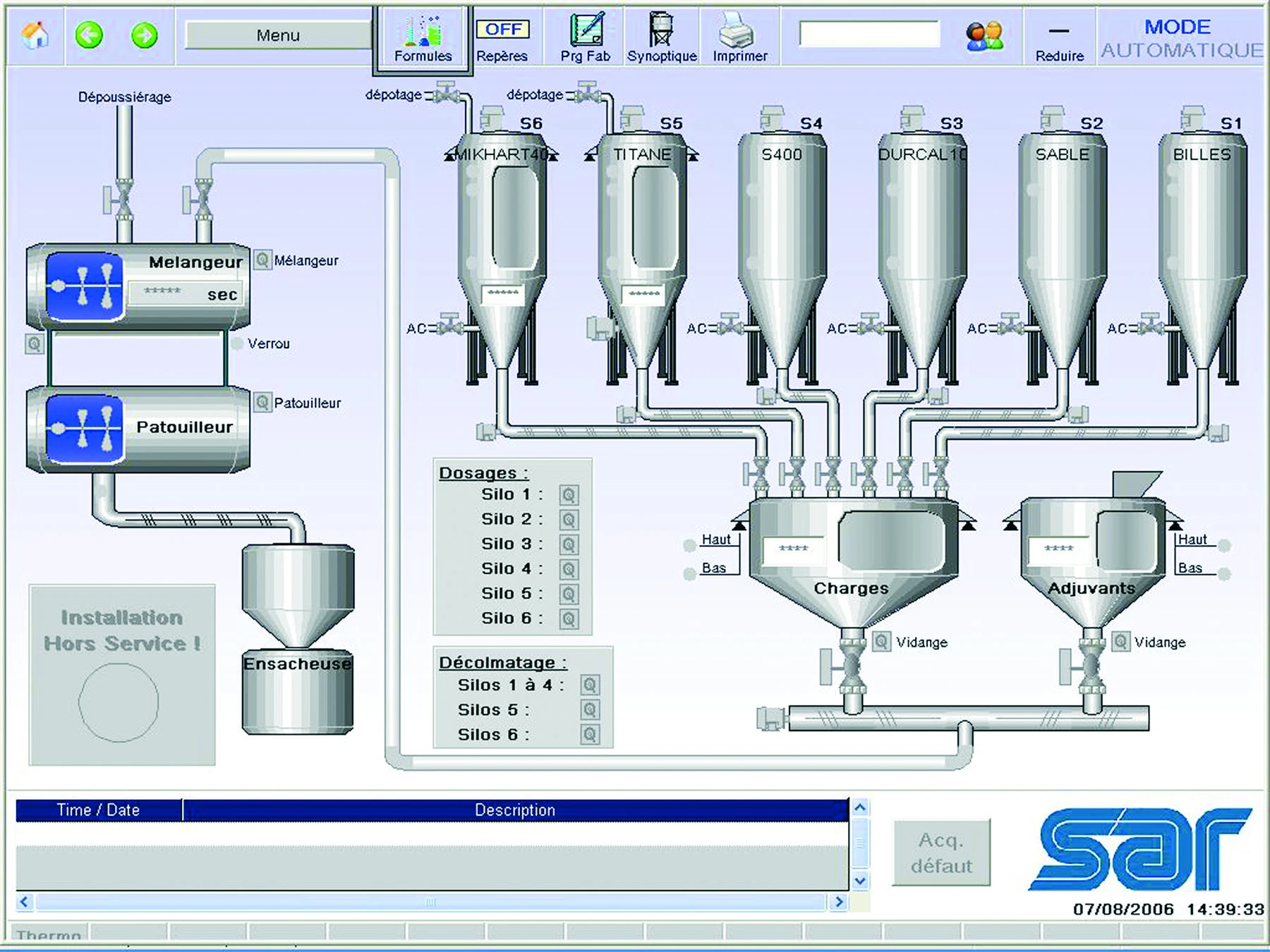

Synoptic Overview of Paint Production

Synoptic Overview of Paint Production

SIGNATURE S.A. selected Mitsubishi Electric Iconics Digital Solutions’ GENESIS™ HMI/SCADA suite, including:

Synoptic Overview of Paint Production

Synoptic Overview of Paint Production

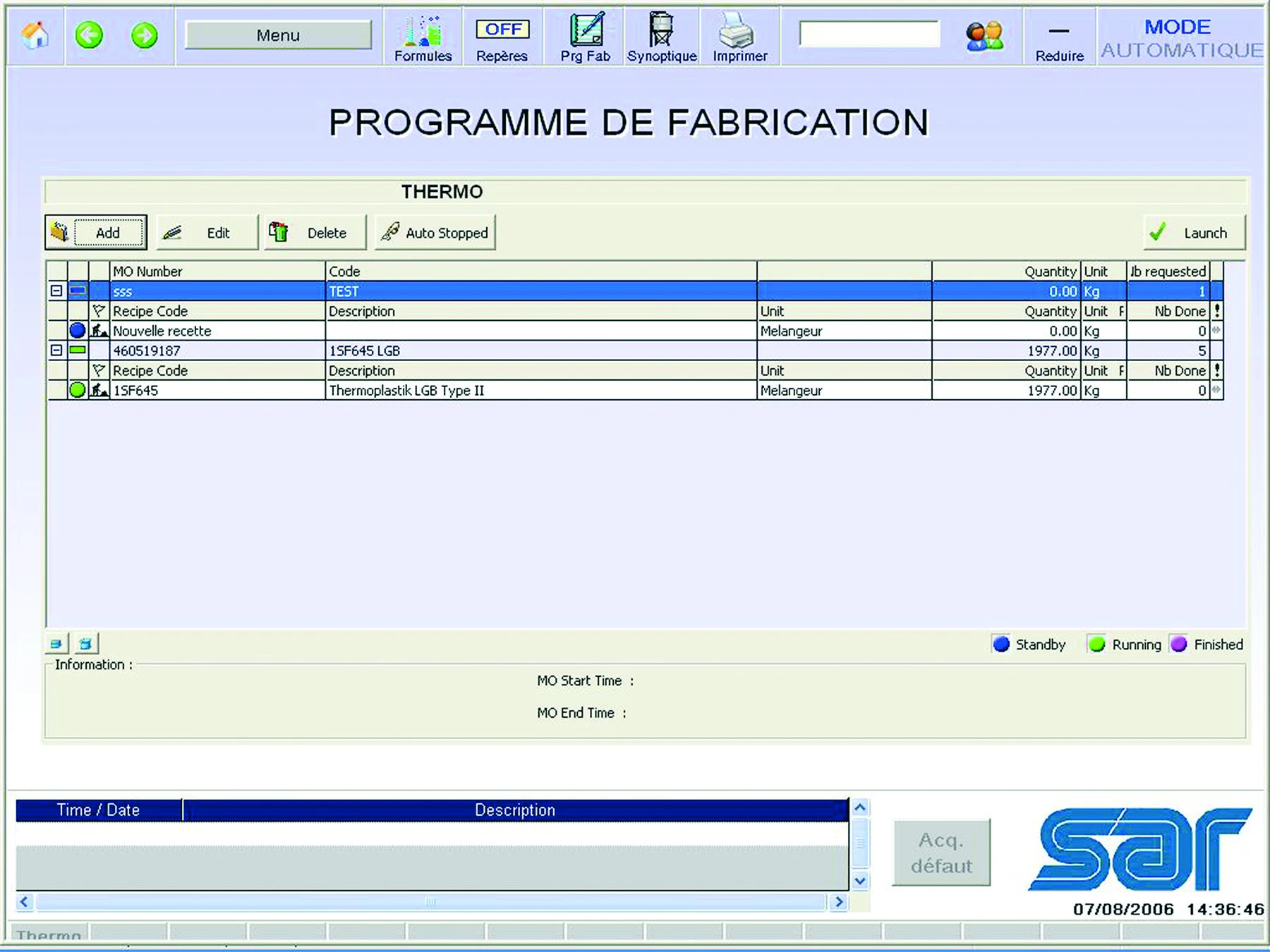

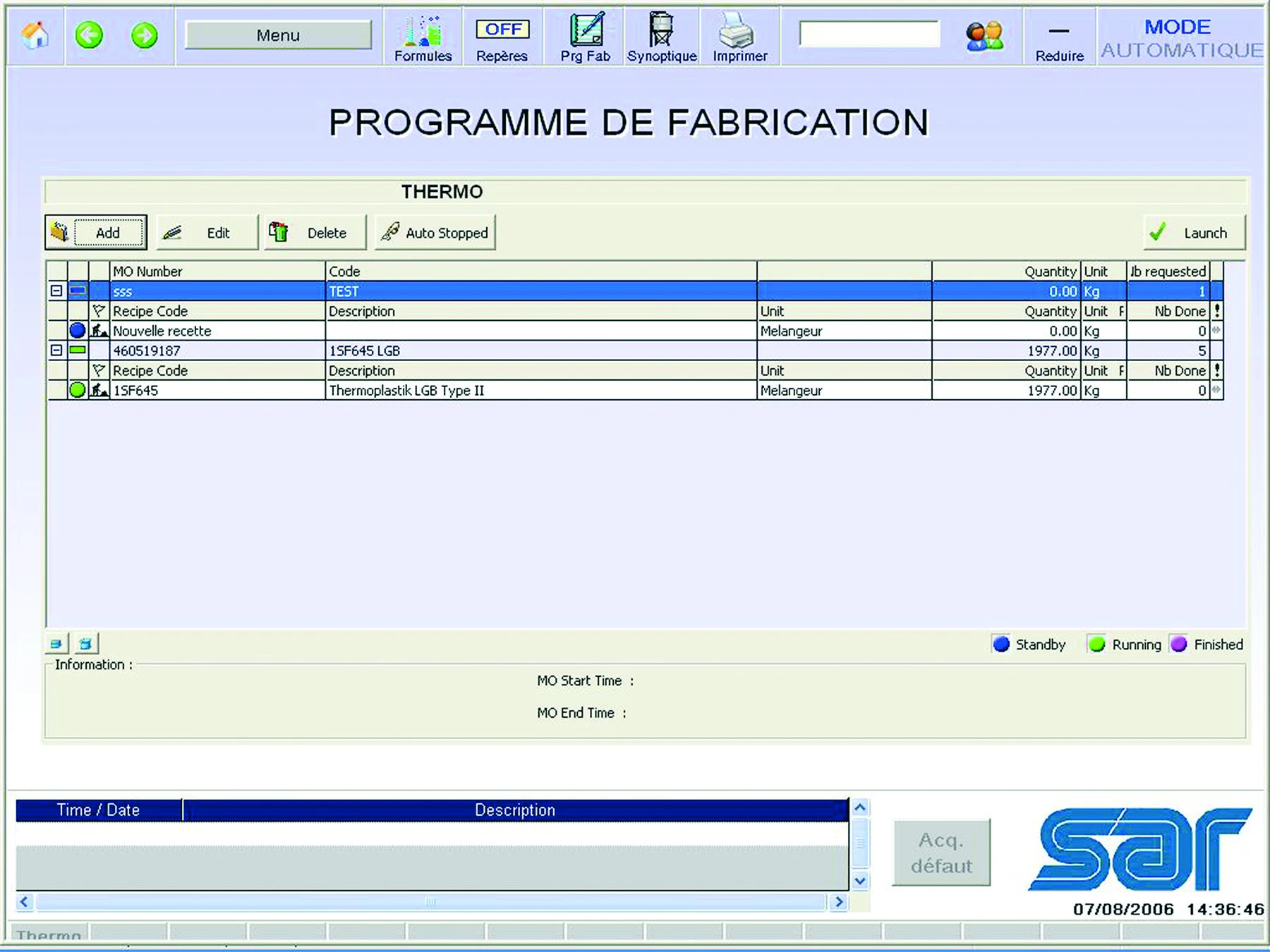

Production Schedule at Signature S.A

Production Schedule at Signature S.A

SIGNATURE S.A. sought a solution to automate its paint plant using a batch process. With the support of system integrator Mitsubishi Electric Iconics Digital Solutions France Process Control, the company implemented GENESIS and BatchWorX to achieve this goal.

GENESIS connected PLCs—most from different suppliers—directly to SIGNATURE S.A.’s system. The AlarmWorX module was installed to ensure traceability, while WebHMI enabled remote control from production manager and process engineer stations.

In addition, SIGNATURE S.A. uses ReportWorX to generate daily alarms and event reports, as well as production data summaries.

ReportWorX also produces:

Production Schedule at Signature S.A

Production Schedule at Signature S.A

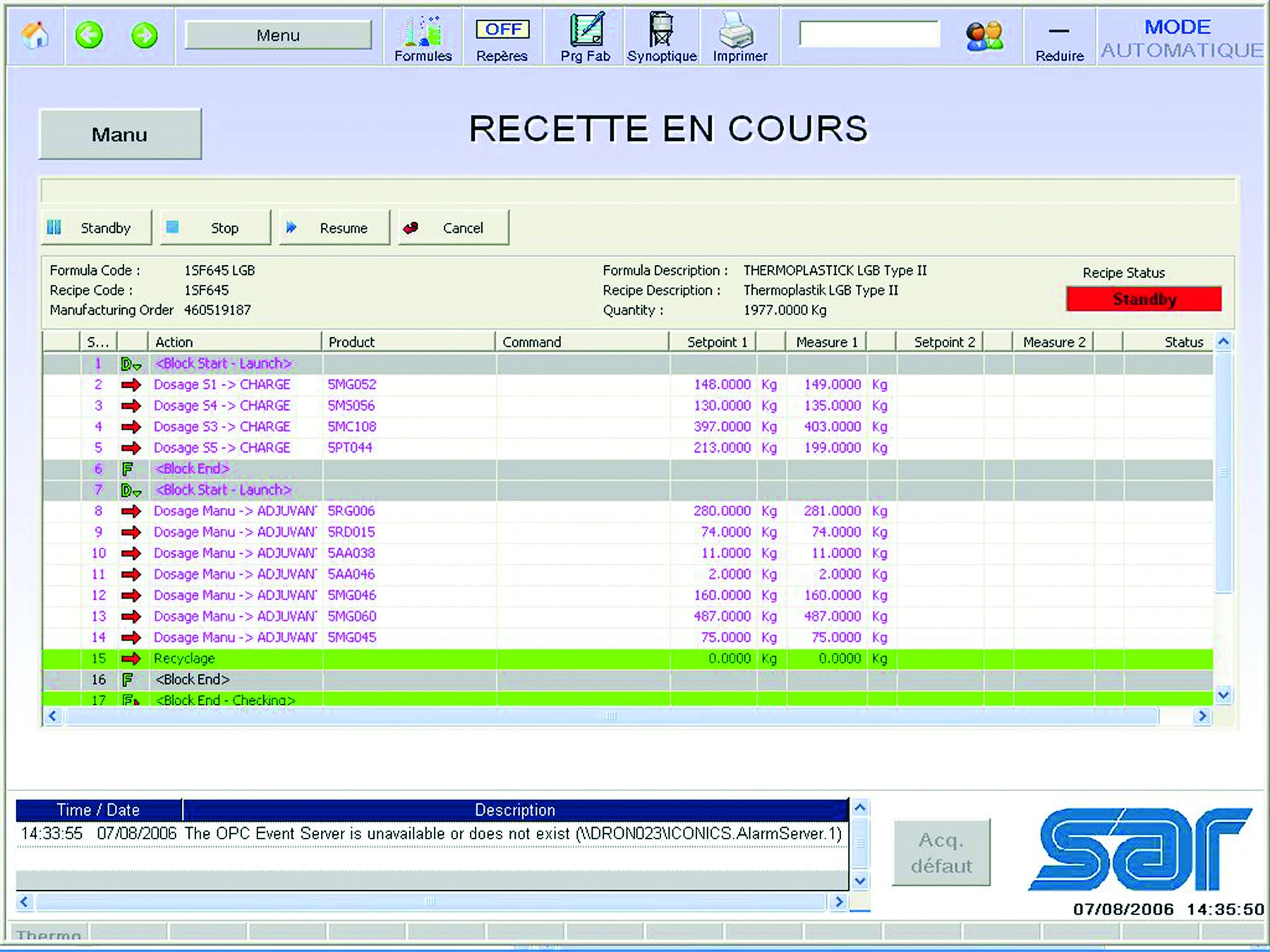

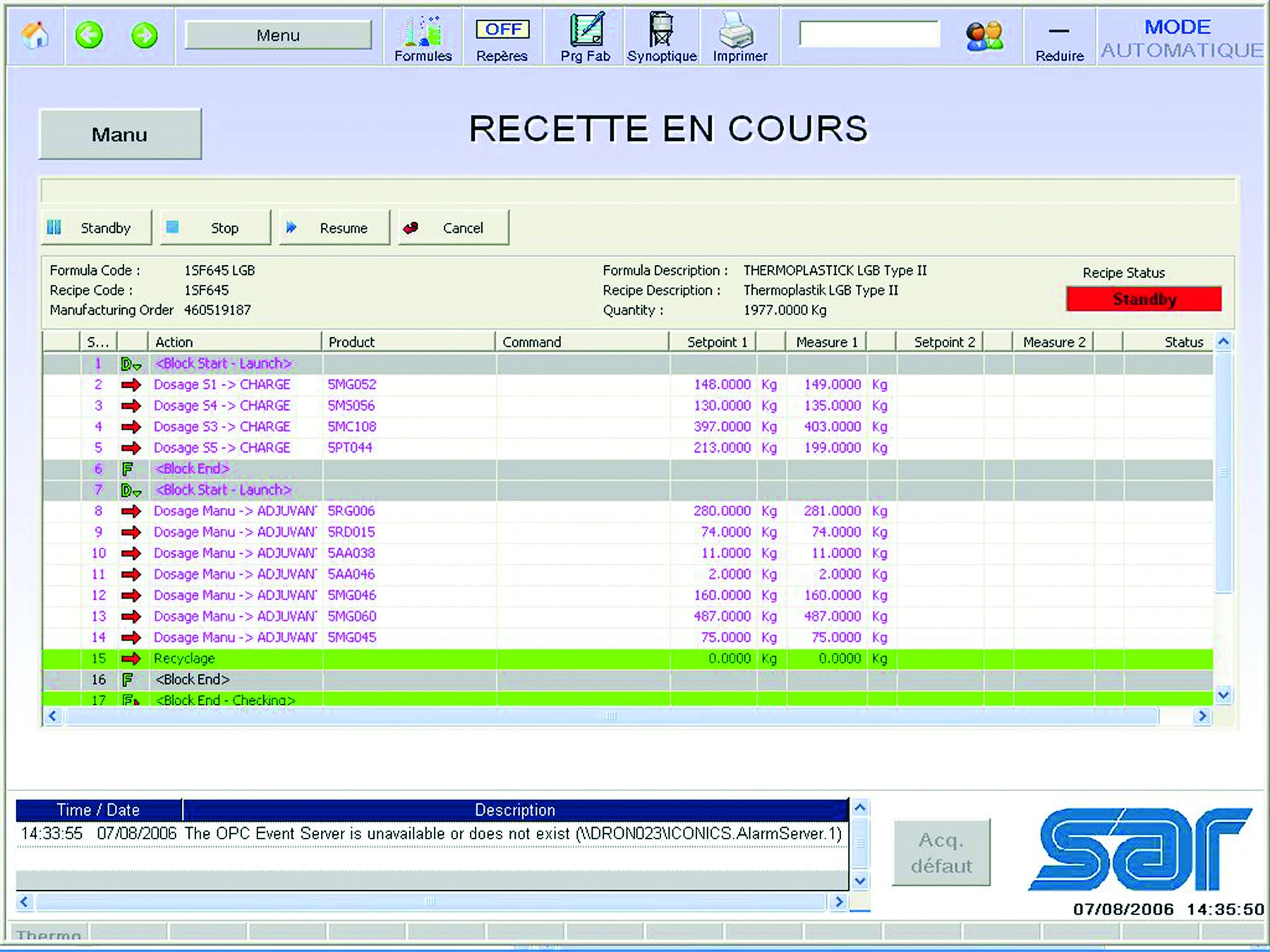

SIGNATURE S.A. Paint Production Recipe in Progress

SIGNATURE S.A. Paint Production Recipe in Progress

SIGNATURE S.A. sought several specific features that GENESIS was able to meet and exceed:

The company planned a three-month project development cycle, followed by an expected three weeks for startup and implementation. Mitsubishi Electric Iconics Digital Solutions, working in tandem with Mitsubishi Electric Iconics Digital Solutions France Process Control, met these time expectations with confidence.

The selected solution also needed to integrate with:

All integration requirements were handled seamlessly by Mitsubishi Electric Iconics Digital Solutions.

SIGNATURE S.A. Paint Production Recipe in Progress

SIGNATURE S.A. Paint Production Recipe in Progress

SIGNATURE S.A. sought an “open and evolving system” to support its paint plant automation. With GENESIS, the company quickly gained state-of-the-art solutions for HMI/SCADA, batch processing, alarm management, and reporting. In addition, SIGNATURE S.A. can easily expand as new needs arise by adding components from Mitsubishi Electric Iconics Digital Solutions’ comprehensive GENESIS HMI/SCADA suite.

SIGNATURE S.A. sought an “open and evolving system” to support its paint plant automation. With GENESIS, the company quickly gained state-of-the-art solutions for HMI/SCADA, batch processing, alarm management, and reporting.

In addition, SIGNATURE S.A. can easily expand as new needs arise by adding components from Mitsubishi Electric Iconics Digital Solutions’ comprehensive GENESIS HMI/SCADA suite—ensuring long-term flexibility, scalability, and continued operational excellence.