Category: Building Automation

Blue Lagoon Iceland

Grindavik, Iceland

Category: Building Automation

Grindavik, Iceland

“Our new GENESIS SCADA system is an immense facelift. We have great visibility into all our sites. Plus, since it is much easier to navigate, our operators have gained new confidence running our technical systems. This upgrade proves to us that having Idnadartaekni implementing GENESIS64 gives the best possible outcome, and we are ready to expand the system further in years to come.”

Located in Grindavík, Iceland, Blue Lagoon Iceland was founded in 1992 to unlock the benefits of geothermal seawater, and in their own words “has evolved into a company encompassing transformative spa experiences, research and development, sustainability, culinary enjoyment, a renowned line of skin care products, and the convergence of hospitality and wellness.”

Blue Lagoon was unintentionally formed as a waste product from energy production in a geothermal power plant near Grindavík, Iceland. The plant produces both electricity and hot water with high temperature geothermal water.

When energy from the water has been harnessed, the wastewater is returned to the surrounding lava field where it is supposed to seep back into the porous ground. However, soon after energy production started, the lava field became clogged with dissolved minerals in the water, forming a lagoon.

Key developments in Blue Lagoon’s evolution include:

Collectively, these milestones transformed Blue Lagoon from an accidental formation into a globally celebrated destination.

“Our new GENESIS SCADA system is an immense facelift. We have great visibility into all our sites. Plus, since it is much easier to navigate, our operators have gained new confidence running our technical systems. This upgrade proves to us that having Idnadartaekni implementing GENESIS64 gives the best possible outcome, and we are ready to expand the system further in years to come.”

Blue Lagoon Overview

Blue Lagoon Overview

Idnadartaekni has been the system integrator for Blue Lagoon for 30 years, delivering PLC automation with visualization on the Mitsubishi Electric Iconics Digital Solutions GENESIS platform.

A leading player in Iceland’s automation field, Idnadartaekni has executed some of the country’s most ambitious automation projects and pioneered new automation methods since its founding in 1991. With extensive expertise, the company designs, programs, installs, and maintains automation systems across sectors such as:

In 1996, Idnadartaekni deployed the first SCADA system at Blue Lagoon using Mitsubishi Electric Iconics Digital Solutions’ original GENESIS for Windows (GFW) and Dynamic Data Exchange (DDE). This system controlled heating, ventilation, lagoon water temperature and quality, and several support systems. It soon became clear, however, that the next-generation GENESIS SCADA with OPC technology would deliver greater:

For the next 20 years, the GENESIS32-based system became an indispensable tool, enabling operators to manage the ever-expanding and increasingly complex Blue Lagoon site. By consolidating diverse technical systems into a single platform, it provided operators with the insights needed for daily operations and maintenance.

As Blue Lagoon continued to grow, the GENESIS32 system and its underlying OPC servers gradually became outdated. Anticipating this challenge—and spurred by the GENESIS32 product lifecycle announcement from Mitsubishi Electric Iconics Digital Solutions—Blue Lagoon managers decided it was time for a major upgrade. Naturally, they selected GENESIS64 as the next platform to power their SCADA system.

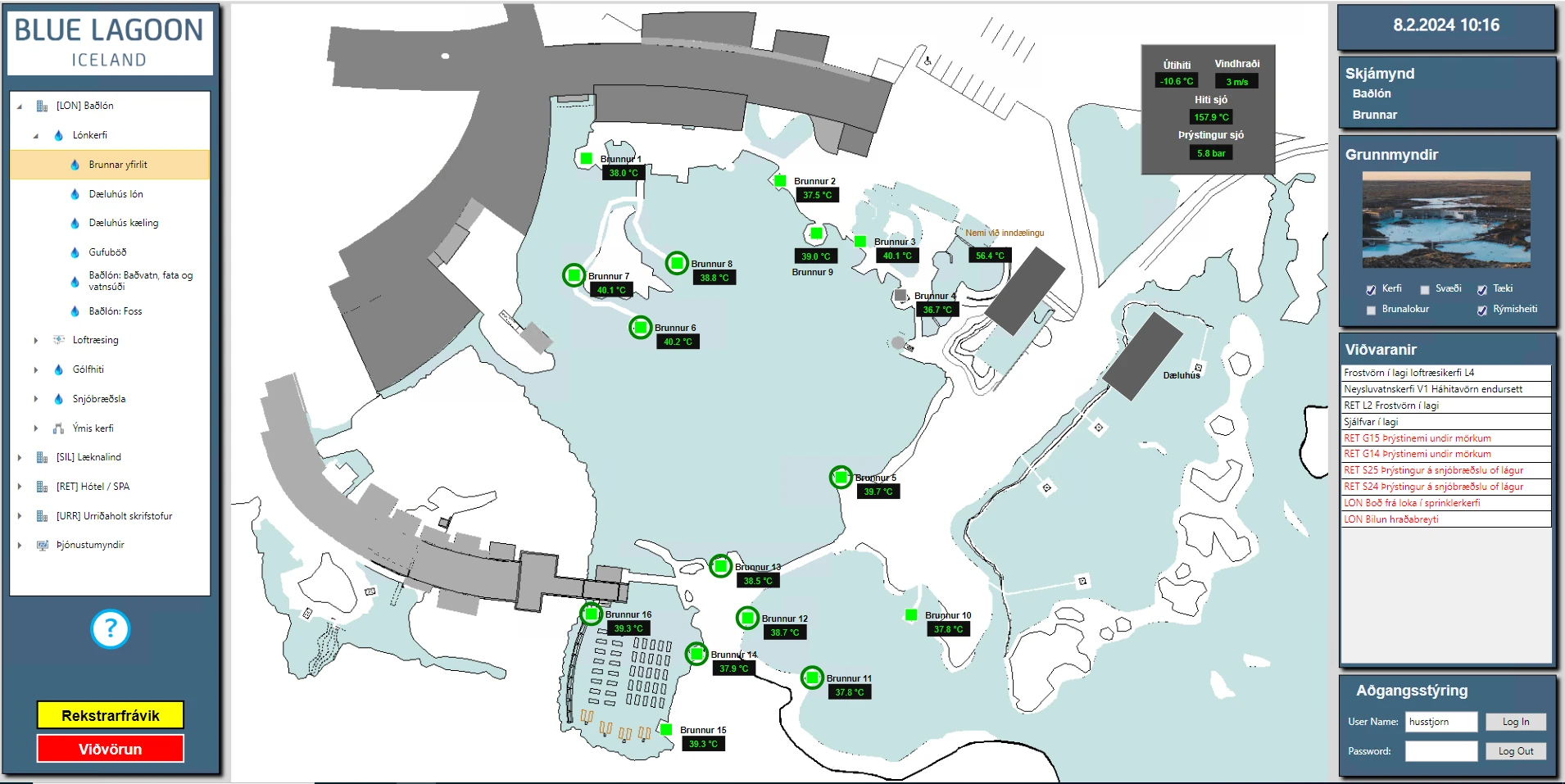

Blue Lagoon Overview

Blue Lagoon Overview

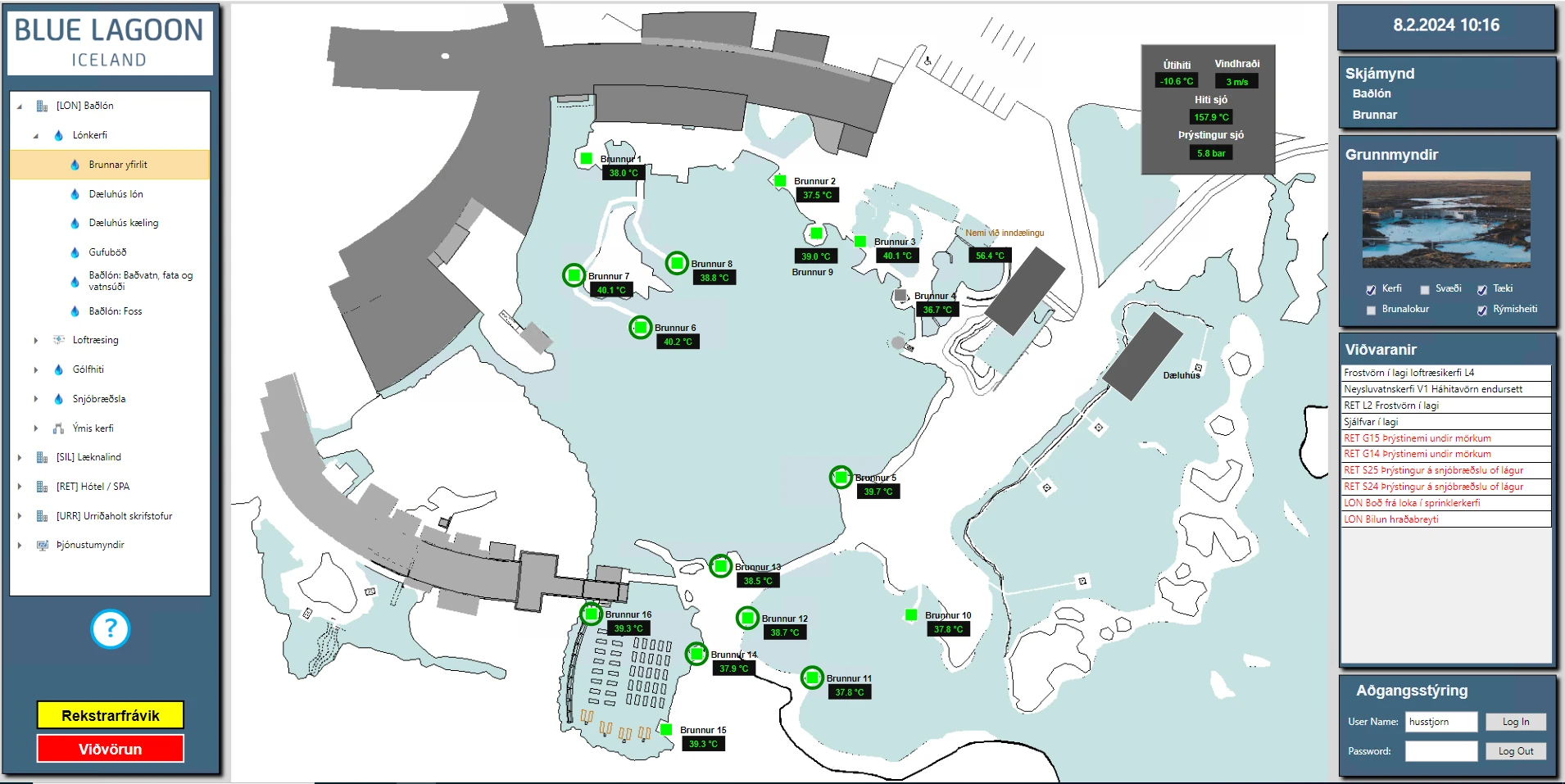

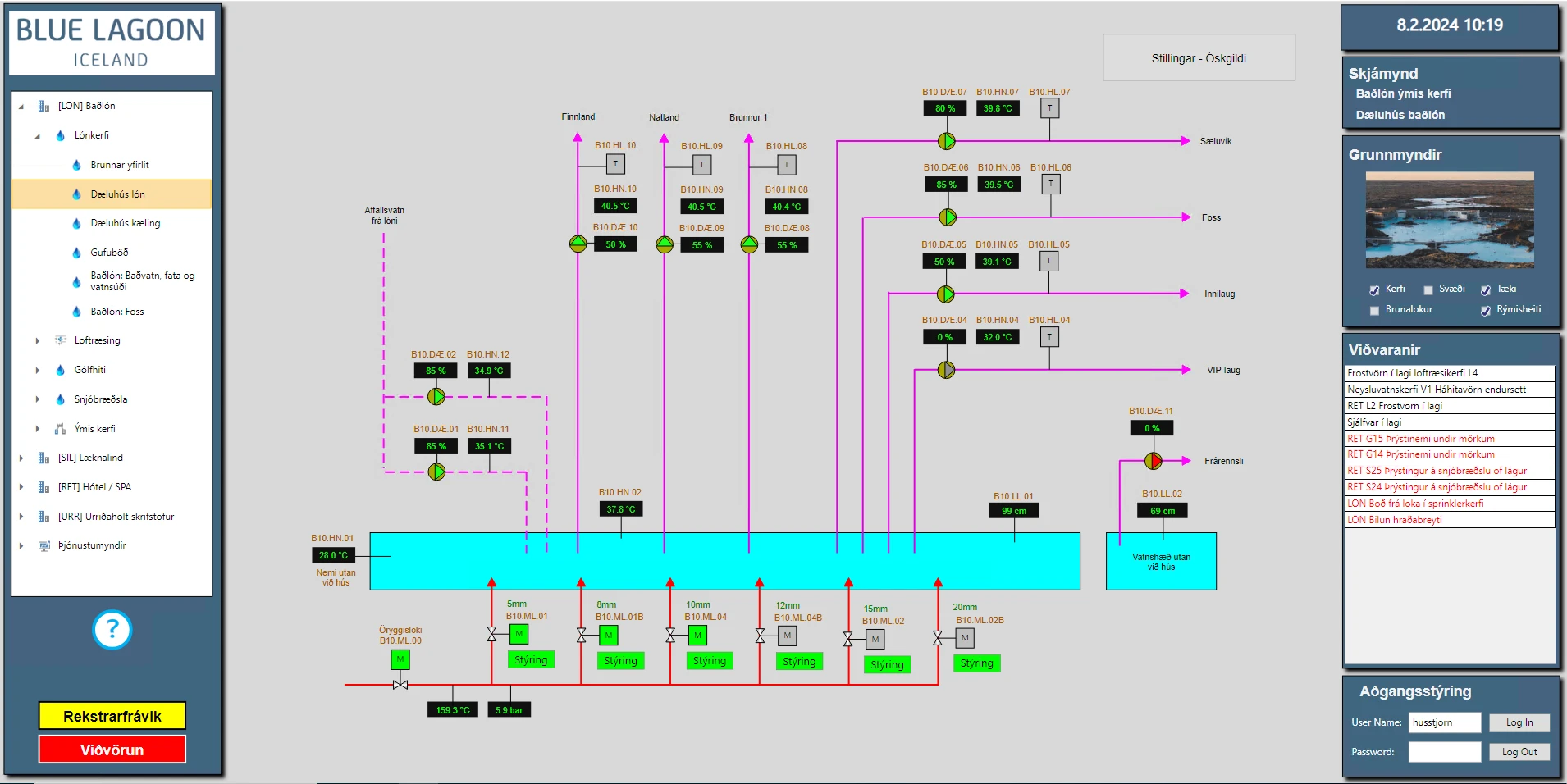

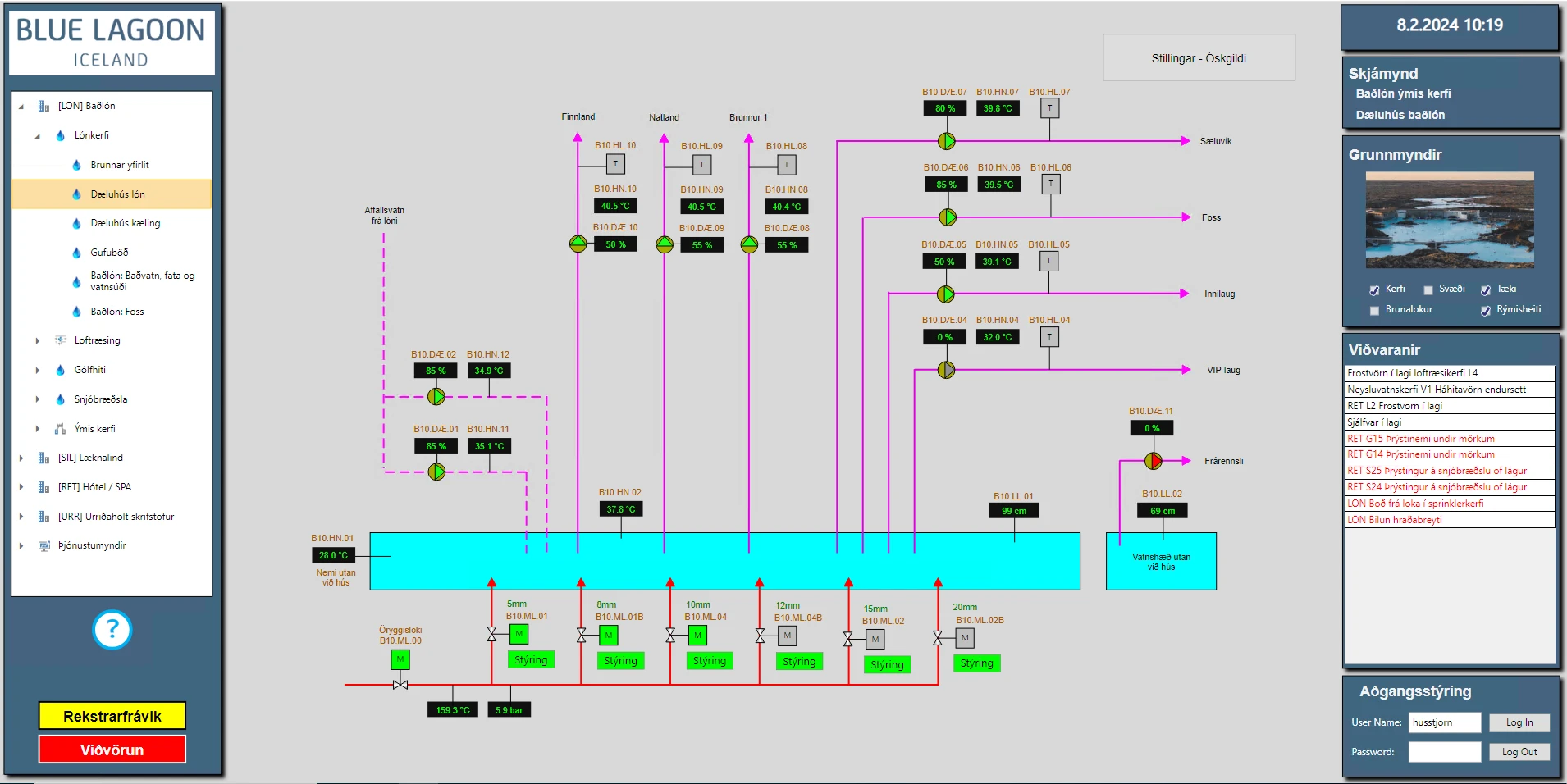

Pumping Station Dashboard

Pumping Station Dashboard

Pumping Station Dashboard

Pumping Station Dashboard

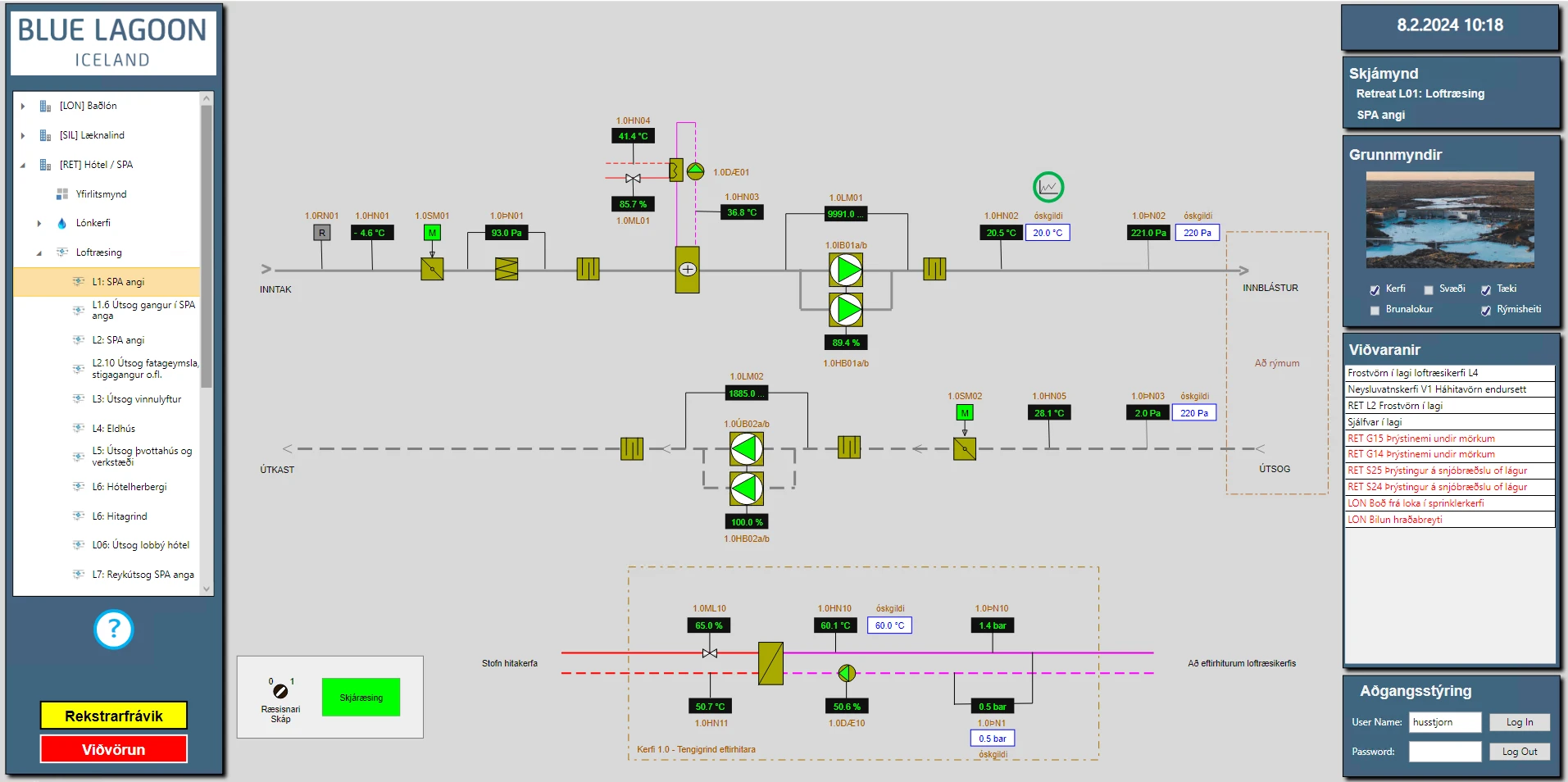

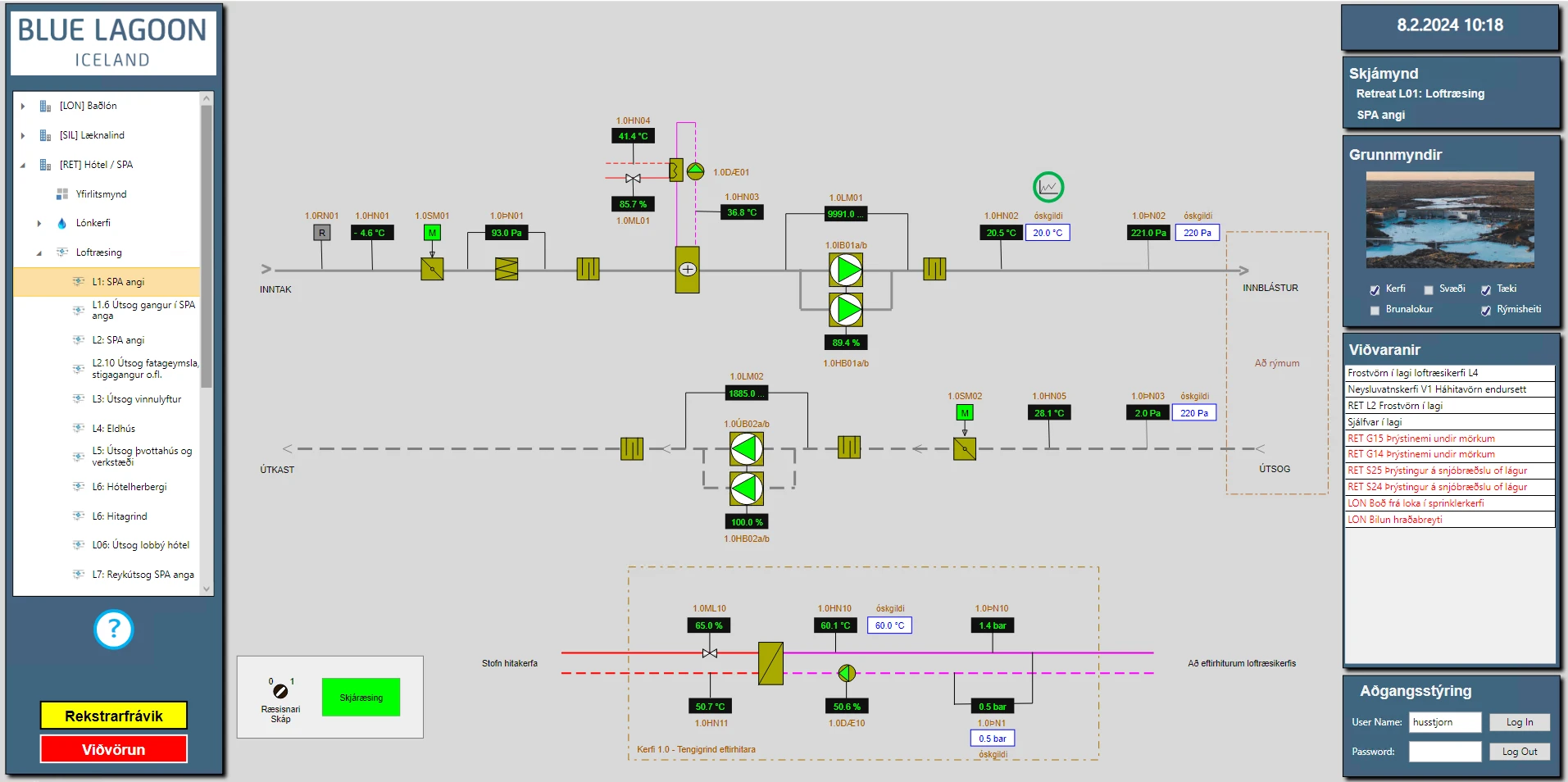

Blue Lagoon’s Air Handling System

Blue Lagoon’s Air Handling System

The Idnadartaekni team successfully migrated Blue Lagoon from GENESIS32 to GENESIS64 in just a couple of weeks. The standard GENESIS64 functionality allowed them to design a robust SCADA system based on principles that ensure effortless long-term maintenance.

Key design features include:

Blue Lagoon’s operators now access the GENESIS64 SCADA system directly through a standard web browser, pulling data from a virtual server. No software installation is needed on user machines, and multiple users can simultaneously configure or monitor different parts of the system—such as data connectivity, alarm servers, trend servers, or displays. The updated navigation tree principle dramatically improves oversight and shortens the time needed to find critical information.

The thin-client, web-based architecture provides further advantages:

Finally, with expert support from Mitsubishi Electric Iconics Digital Solutions readily available, Idnadartaekni benefits from prompt issue resolution, valuable insights, and improved productivity.

Blue Lagoon’s Air Handling System

Blue Lagoon’s Air Handling System

Building Layout Overview

Building Layout Overview

Since the old system was kept running in parallel with the new one for several weeks, operators had the opportunity to compare both environments side by side and suggest adjustments.

This approach ensured that the migration from GENESIS32 to GENESIS64 was exceptionally smooth, minimizing disruption and building confidence in the new setup. The parallel operation also allowed operators to validate real-world functionality before fully transitioning, making the process seamless and efficient.

Today, Blue Lagoon management and operators are highly satisfied with the new GENESIS64 system. They recognize it as not only stable and reliable but also futureproof—capable of supporting the site’s continuous growth and increasing complexity. With GENESIS64 in place, the facility now has a robust foundation that ensures scalability, operational excellence, and the ability to adapt to evolving requirements well into the future.

Building Layout Overview

Building Layout Overview