Category: Food and Beverage , Building Automation

Catania Oils

Ayer, Massachusetts, United States

Category: Food and Beverage , Building Automation

Ayer, Massachusetts, United States

“We collect data regularly through GENESIS. And so, we get data from every line, from every product, and from every shift, and that data is accumulated in the database and a report comes out every day for us to be able to determine how each one of those lines is running.”

Catania Oils is a leading provider of conventional, non-GMO Project verified and organic oils for the ingredients, foodservice, and retail markets. The company is driven by their steadfast commitment to excellence and continuous improvement processes that deliver the highest quality of vegetable, olive, and blended oils to the industry and its customers around the world.

The company operates a high-tech manufacturing facility, a large distribution center, a quality assurance (QA) laboratory, a railroad and bulk processing area as well as multiple automatic production lines. In addition, Catania Oils also operates a fleet of tank and box trucks, allowing them to service customers throughout the United States.

“We collect data regularly through GENESIS. And so, we get data from every line, from every product, and from every shift, and that data is accumulated in the database and a report comes out every day for us to be able to determine how each one of those lines is running.”

Operations Dashboard

Operations Dashboard

Catania Oils knew they needed help in leveraging their data. Specifically, they needed to zero in on the informational insight that this data could provide for plantwide visualization into production. In particular, the company wanted:

They therefore set out to look for an automation software that could capture the data and display it in a meaningful way for them to make data-driven decisions.

Catania Oils was introduced to system integrator Data Acuity, and as a longtime partner of Mitsubishi Electric Iconics Digital Solutions, Data Acuity chose GENESIS for the system automation software. Located in Hampton, New Hampshire, Data Acuity is an automation software company that focuses on the manufacturing, energy, and service delivery efficiency for Automated Systems. Their consulting services, the technologies they represent, and their engineering design efforts are all centered on focusing their clients’ resources on areas that will bring the greatest efficiency gains.

Operations Dashboard

Operations Dashboard

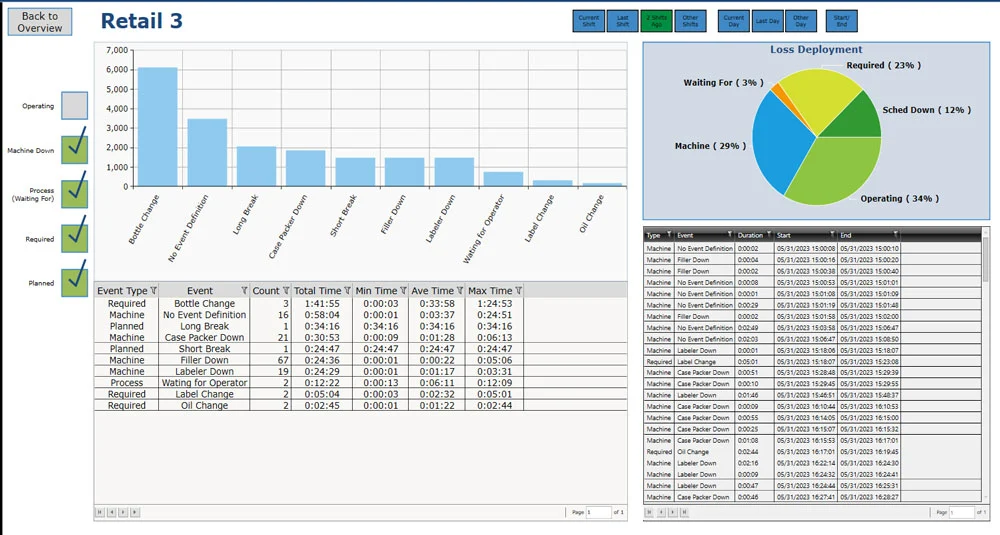

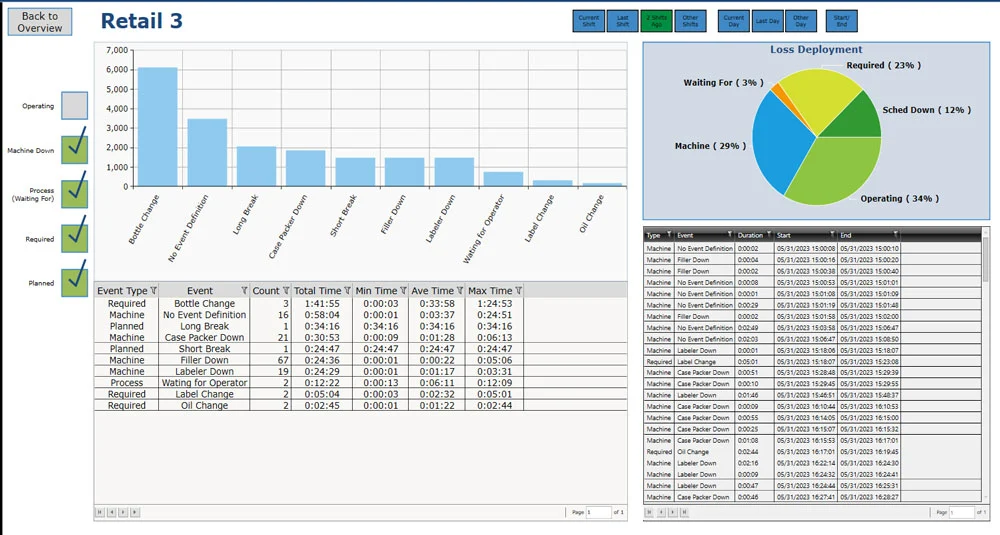

Operations Pareto Chart/Loss Deployment Pie Chart

Operations Pareto Chart/Loss Deployment Pie Chart

Operations Pareto Chart/Loss Deployment Pie Chart

Operations Pareto Chart/Loss Deployment Pie Chart

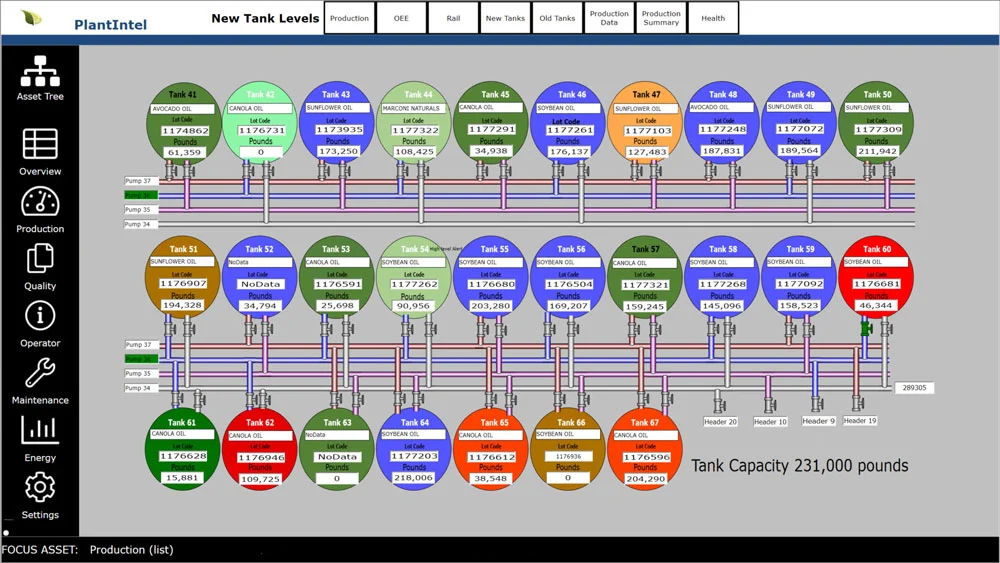

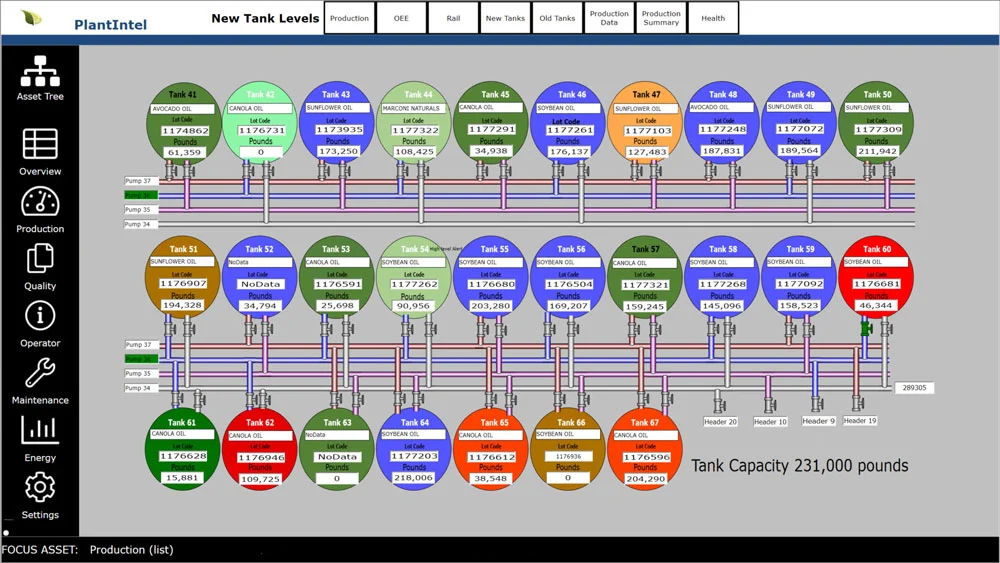

Tank Level Overview

Tank Level Overview

GENESIS software allowed Catania Oils to monitor overall equipment effectiveness (OEE) and loss deployment to improve production efficiency. The key was to focus the right resources on the right problems and to use OEE for gaining insight.

As a metric, OEE provided a clear understanding of the difference between the quantity of sellable product that could be made versus the actual quantity produced. The primary insight gained from this metric was a full understanding of which resources needed to be assigned to which priority problems.

Using GENESIS, Catania Oils could measure production efficiency by breaking OEE into three components:

Additionally, the company improved efficiency by monitoring loss deployment. With GENESIS, Catania Oils could determine:

By monitoring both OEE and loss deployment, Catania Oils gained deeper insight into potential efficiency losses and could focus on the entire production process, rather than only on a single machine fault or quality defect—leading to even greater efficiency gains.

Tank Level Overview

Tank Level Overview

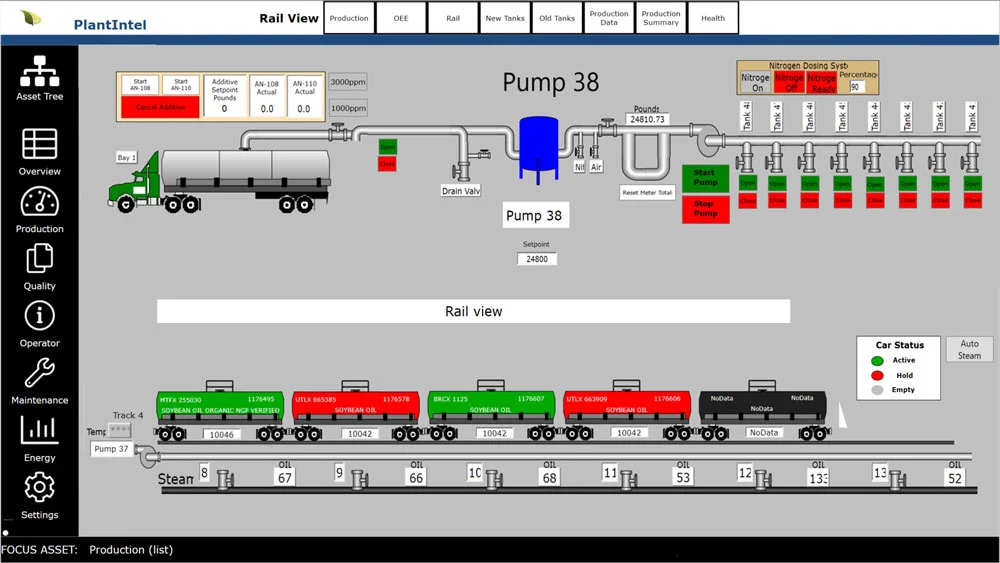

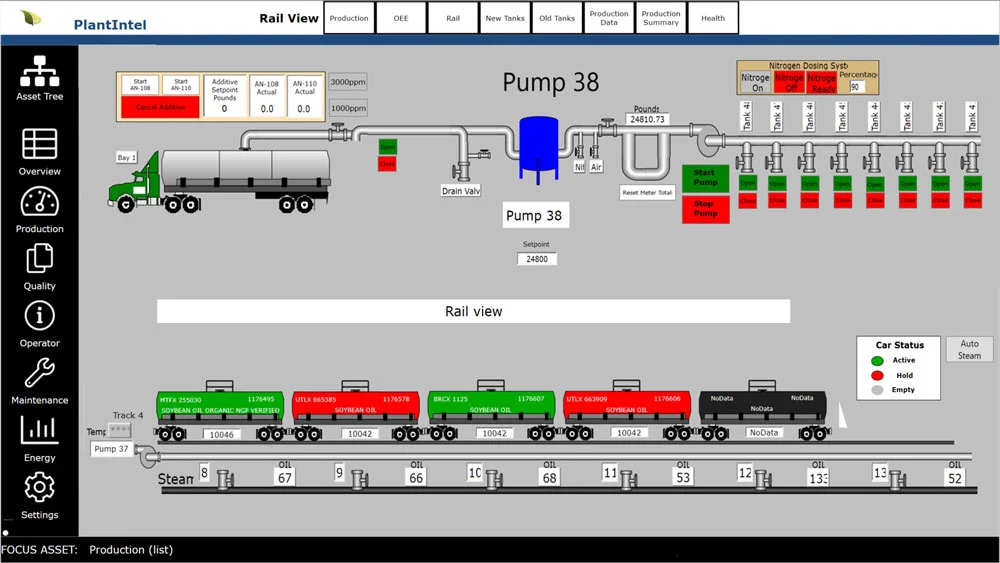

Pump and Rail Operations

Pump and Rail Operations

Catania Oils will continue to use Mitsubishi Electric Iconics Digital Solutions’ software to optimize their operations and are now using the software to look into predictive maintenance. By leveraging GENESIS’ real-time data and analytics, they are identifying patterns and trends that help anticipate potential equipment issues before they occur.

They are correlating their production information with the CMMS system in order to schedule maintenance actions predictively as opposed to scheduling maintenance actions based on a calendar. This proactive approach not only reduces unplanned downtime but also extends the life of critical assets.

The company plans to continue to grow their expertise and experience in using GENESIS for continuous improvement across all aspects of their operations.

Pump and Rail Operations

Pump and Rail Operations