Category: Water and Wastewater

Oceanium

Rotterdam, Netherlands

Category: Water and Wastewater

Rotterdam, Netherlands

“The Oceanium is the “water world” of the Diergaarde Blijdorp Zoo in Rotterdam, Netherlands. This portion of the zoo contains a whale exposition, a public laboratory, a coral reef, a kelp forest, a bird rock, and, what many visitors consider the most impressive, enormous sharks. Oceanium’s water consists entirely of clean sea water, regularly refreshed for the inhabitants of its exhibits.”

“The Oceanium is the “water world” of the Diergaarde Blijdorp Zoo in Rotterdam, Netherlands. This portion of the zoo contains a whale exposition, a public laboratory, a coral reef, a kelp forest, a bird rock, and, what many visitors consider the most impressive, enormous sharks. Oceanium’s water consists entirely of clean sea water, regularly refreshed for the inhabitants of its exhibits.”

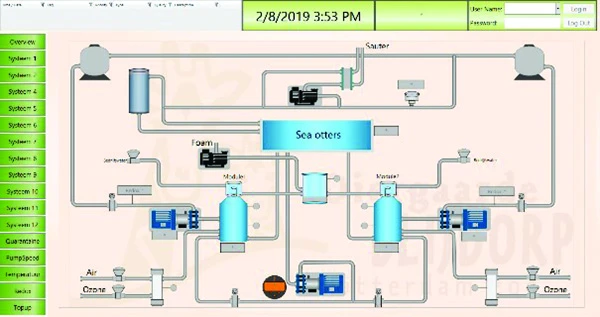

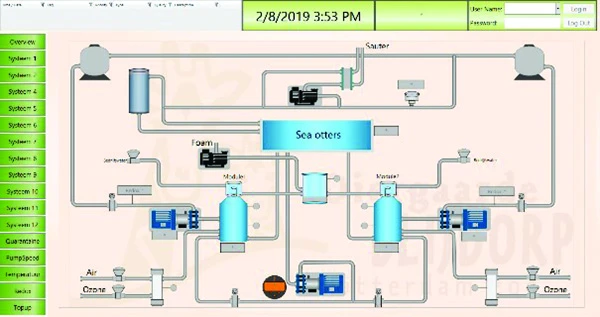

GENESIS64™-created Control Screen for One of Oceanium’s Refreshed Sea Water Environments

GENESIS64™-created Control Screen for One of Oceanium’s Refreshed Sea Water Environments

The Oceanium at Diergaarde Blijdorp Zoo, working with system integrator, Koning & Hartman in Amsterdam, Netherlands, selected GENESIS64™ HMI/SCADA and building automation software suite.

GENESIS64™-created Control Screen for One of Oceanium’s Refreshed Sea Water Environments

GENESIS64™-created Control Screen for One of Oceanium’s Refreshed Sea Water Environments

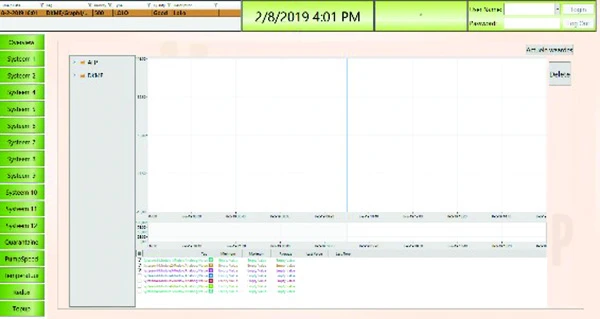

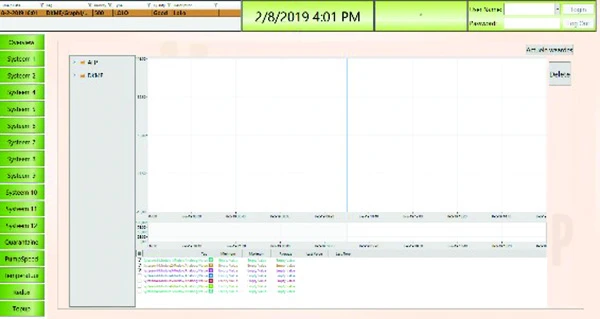

Overview Screen at Diergaarde Blijdorp Zoo

Overview Screen at Diergaarde Blijdorp Zoo

Every month, nearly five percent of the Oceanium‘s water is refreshed so that the sharks, tropical fish, corals, king penguins, sea lions and polar bears can safely swim around. What many people may not know is that large filter installations are needed to change the water in such installations in order to keep them habitable for the animals. Multiple PLCs ensure that these filter installations work and water is pumped exactly where it needs to be.

From these PLCs, data can then be acquired to check whether everything is running smoothly during the water refresh process. The filtering of the water from the animal enclosures in the Oceanium is controlled with the help of Mitsubishi PLCs. The Oceanium’s older PLCs had reached end-of-life and had to be replaced. The new PLCs now help to ensure that the filter systems within the Oceanium run flawlessly. Along with the new Mitsubishi IQ-F series PLCs, the Oceanium also recognized the need for a new HMI/SCADA installation.

Multiple data points can be extracted from these connected systems, such as the water level of a basin, the temperature of the water in the penguin stay, or which pumps are on. This data can be visualized via a central network. This is where Mitsubishi Electric Iconics Digital Solutions comes in. The Smart Industry team of Koning & Hartman implemented GENESIS64 to help monitor and manage Oceanium’s multiple connected operations.

Overview Screen at Diergaarde Blijdorp Zoo

Overview Screen at Diergaarde Blijdorp Zoo

Additional Control Screen at Diergaarde Blijdorp Zoo

Additional Control Screen at Diergaarde Blijdorp Zoo

Thanks to the user-friendliness of GENESIS64, dashboards were set up quickly and easily. With this solution, Diergaarde Blijdorp Zoo staff has real-time insight into the status of all animal enclosures within the Oceanium. Alarms are generated if something goes wrong in one of the accommodations. A trend overview can be made of, for example, the water level of the shark tank over the past year. With the new system, employees can now view the current status of the processes in the Oceanium via the system with their smartphone.

Mitsubishi Electric Iconics Digital Solutions was chosen by Oceanium from a short list of competitive offerings. Ultimately, GENESIS64 was selected due to its familiar look and feel, price, and ability for quick deployment. Operators feel they have installed a future-proof solution that provides insight into their operations via detailed dashboards. Because the entire implementation was made in collaboration with Diergaarde Blijdorp Zoo’s technical department, they feel their collaboration and knowledge sharing led to a successful project, with no anticipation of any future dependence on a third-party. In the end, Oceanium staff based their opinion of their newly installed GENESIS64 installation on some “satisfied sharks”.

Additional Control Screen at Diergaarde Blijdorp Zoo

Additional Control Screen at Diergaarde Blijdorp Zoo

Diergaarde Blijdorp Zoo’s Oceanium operators found that GENESIS64’s ease of use can be extended throughout its systems. With additional training, the zoo plans to deploy and expand the application further. Under consideration is future integration with the zoo’s energy management system (EMS) to hopefully satisfy more than just the sharks.