Category: Oil and Gas

Badger Midstream

Panhandle, Texas, USA

Category: Oil and Gas

Panhandle, Texas, USA

“Badger Midstream is a natural gas/natural gas liquids transportation, gathering and processing midstream company created to acquire and exploit midstream assets in the natural gas energy sector. They selected Mitsubishi Electric Iconics Digital Solutions' GENESIS™, HMI/SCADA suite, WebHMI™, and MobileHMI™ to control all the processes of their gas plant.”

Badger Midstream, located in Houston, Texas, is a natural gas/natural gas liquids transportation, gathering and processing midstream company created to acquire and exploit midstream assets in the natural gas energy sector. It was found to significantly improve the midstream value chain by working with customers (producers, operators, pipelines, end users and other midstream companies) to determine needs and provide real, creative, cost effective, technical, results-oriented solutions.

“Badger Midstream is a natural gas/natural gas liquids transportation, gathering and processing midstream company created to acquire and exploit midstream assets in the natural gas energy sector. They selected Mitsubishi Electric Iconics Digital Solutions' GENESIS™, HMI/SCADA suite, WebHMI™, and MobileHMI™ to control all the processes of their gas plant.”

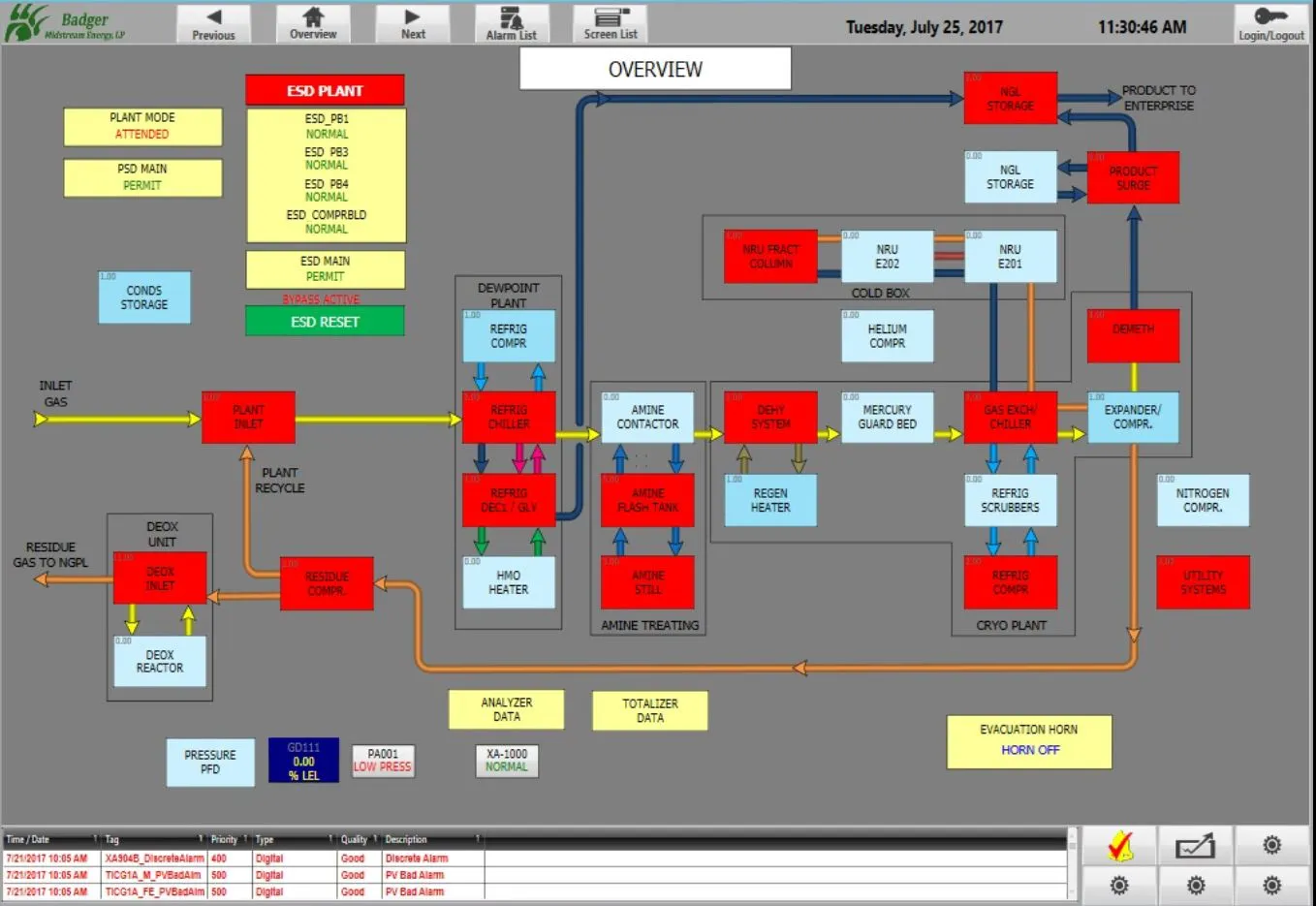

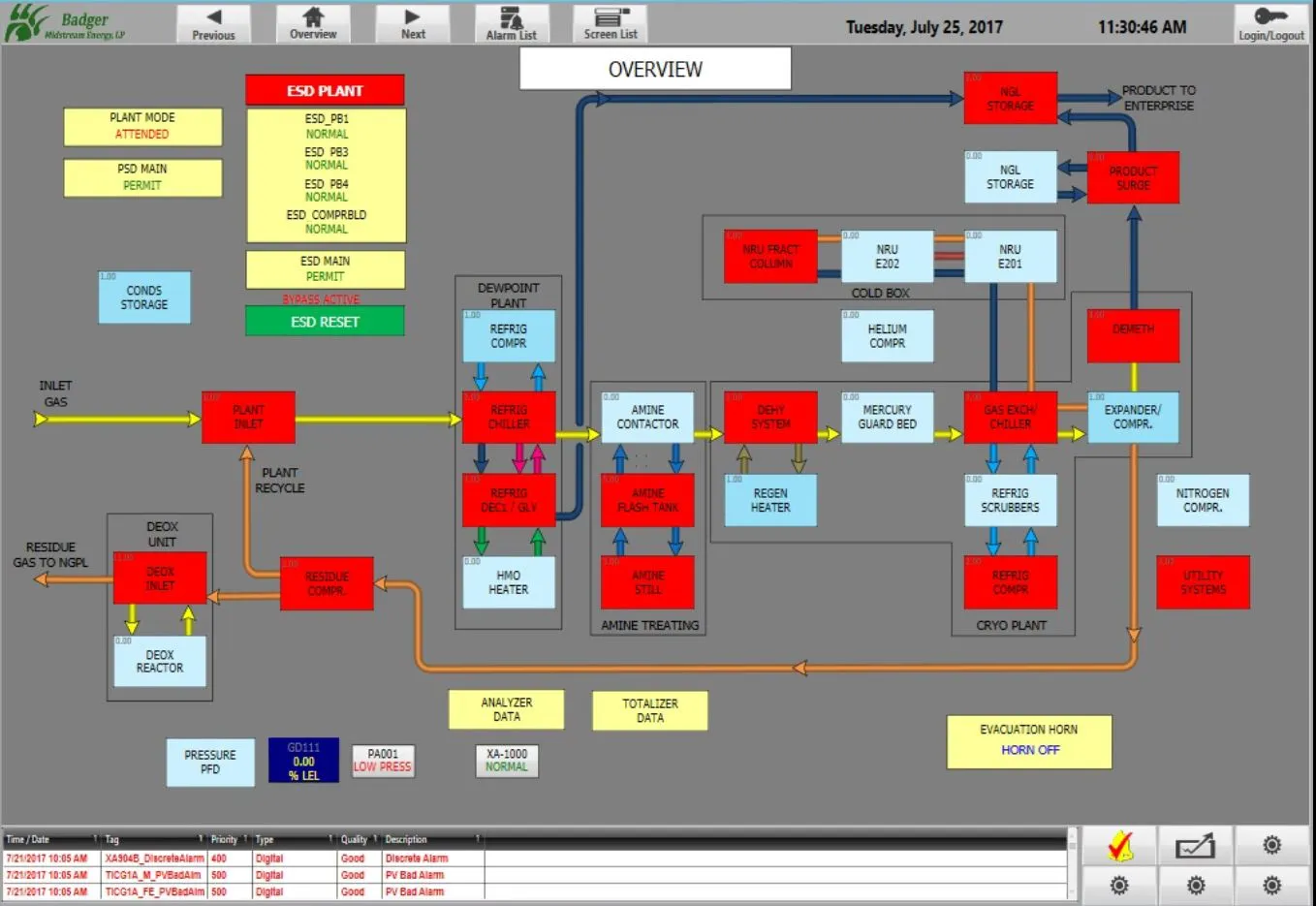

Grey Badger Plant Overview Created via GENESIS64™

Grey Badger Plant Overview Created via GENESIS64™

Badger Midstream, working with system integrator, SOAP Engineering, selected GENESIS64™ HMI/SCADA suite, including WebHMI™ Web-based real-time automation software, as well as the MobileHMI™ data mobility suite.

Grey Badger Plant Overview Created via GENESIS64™

Grey Badger Plant Overview Created via GENESIS64™

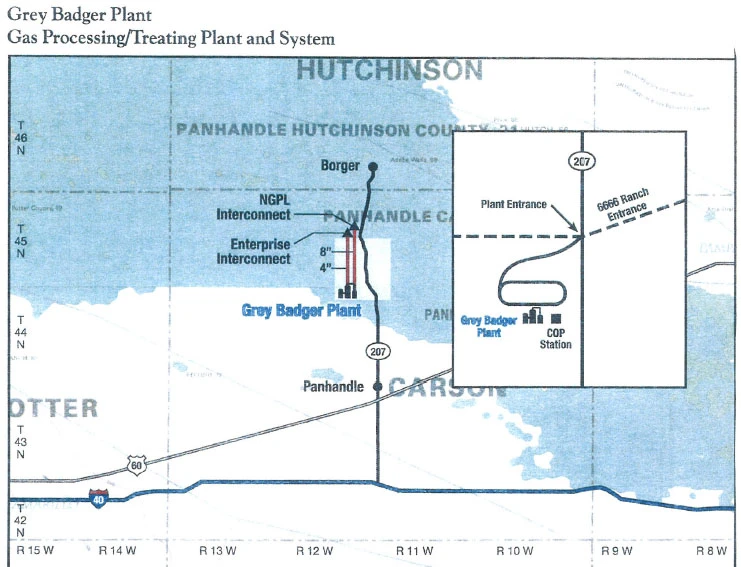

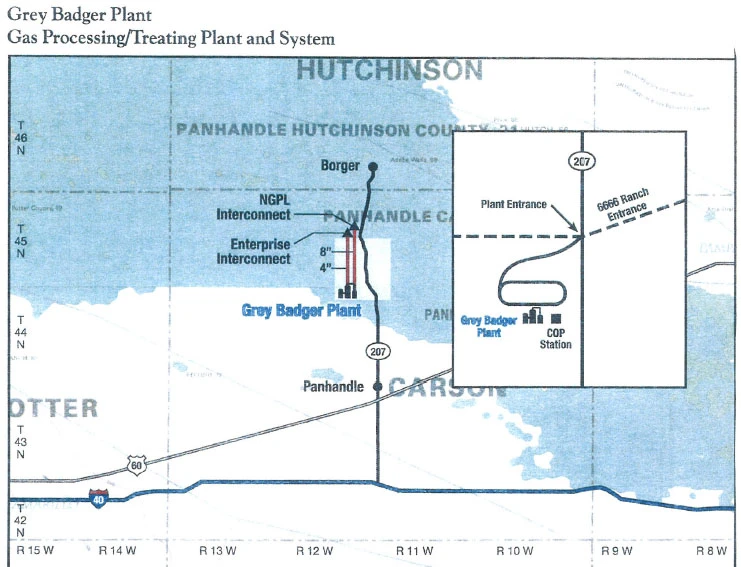

System Map of Grey Badger Plant

System Map of Grey Badger Plant

Badger Midstream’s Grey Badger site in Panhandle, Texas is a cryogenic gas processing and treatment plant. Initial capacity of the plant is 25,000 Mcf/d. It has four miles of steel NGL pipeline and 4.5 miles of 8’ steel high pressure residue pipeline. The plant is an ultra-high recovery cryo plant with ethane rejection capability, amine treating, nitrogen rejection, helium recovery, and condensate stabilization.

The company sought an HMI/SCADA solution to control all the processes of the Grey Badger gas plant including plant metering, compression monitoring, tank/pump/valve control, and the monitoring and control of 105 proportional-integral-derivative (PID) control loops. The new solution would replace an existing system based on a combination of two competitor products due to lack of support of their installed product versions and comparatively high costs of upgrades and yearly/ongoing maintenance charges. Understandably, Badger wanted their new solution to be more cost-effective and easier to maintain.

The selected HMI/SCADA would need to integrate with the plant’s DeltaV DCS control, Allen Bradley controllers, Emerson OPC Server, and various electronic flow meter (EFM) remote terminal units (RTUs), as well as with various plant equipment including heaters, dehydrators, vapor recovery units, separators, heat exchanges and more.

System Map of Grey Badger Plant

System Map of Grey Badger Plant

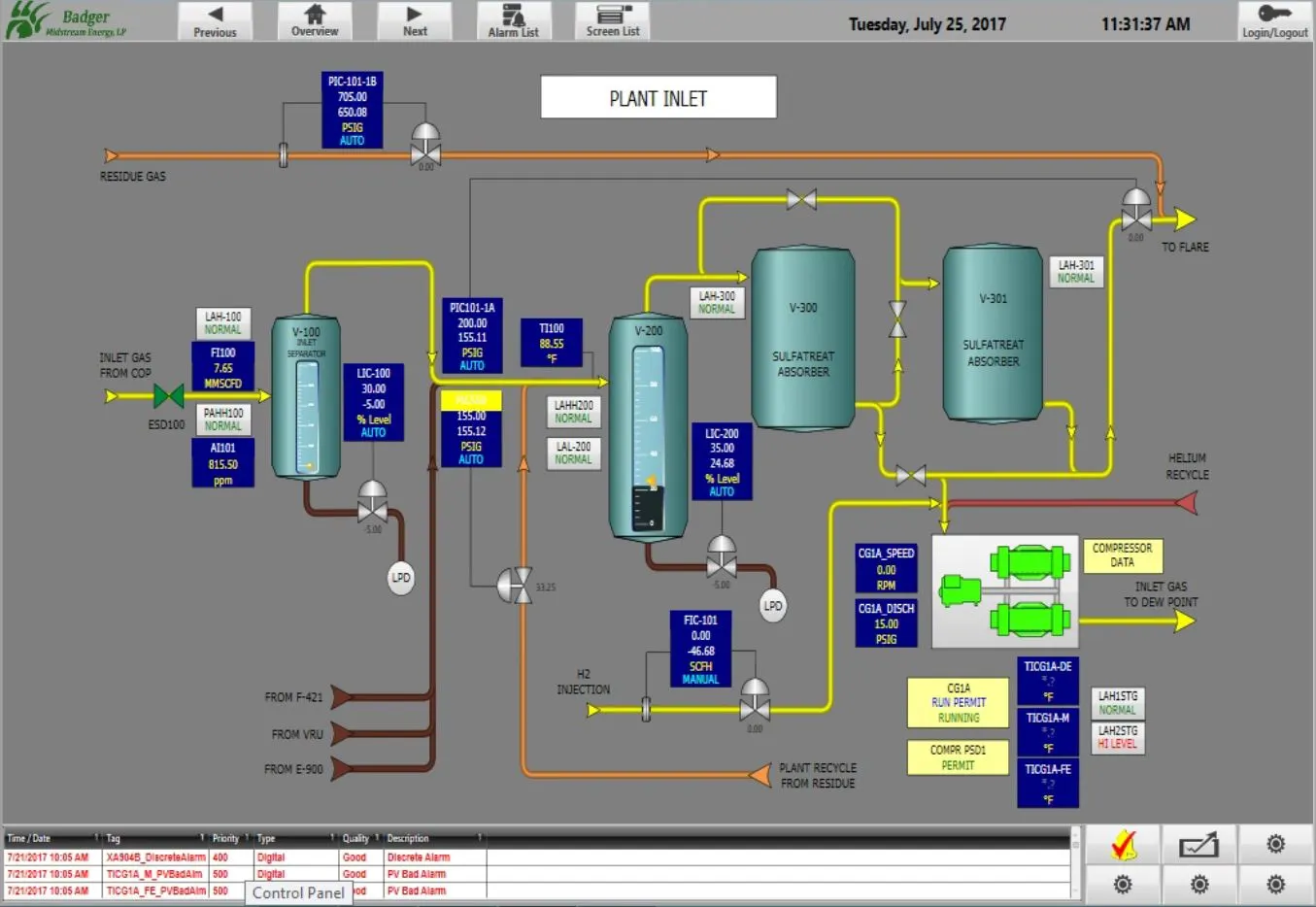

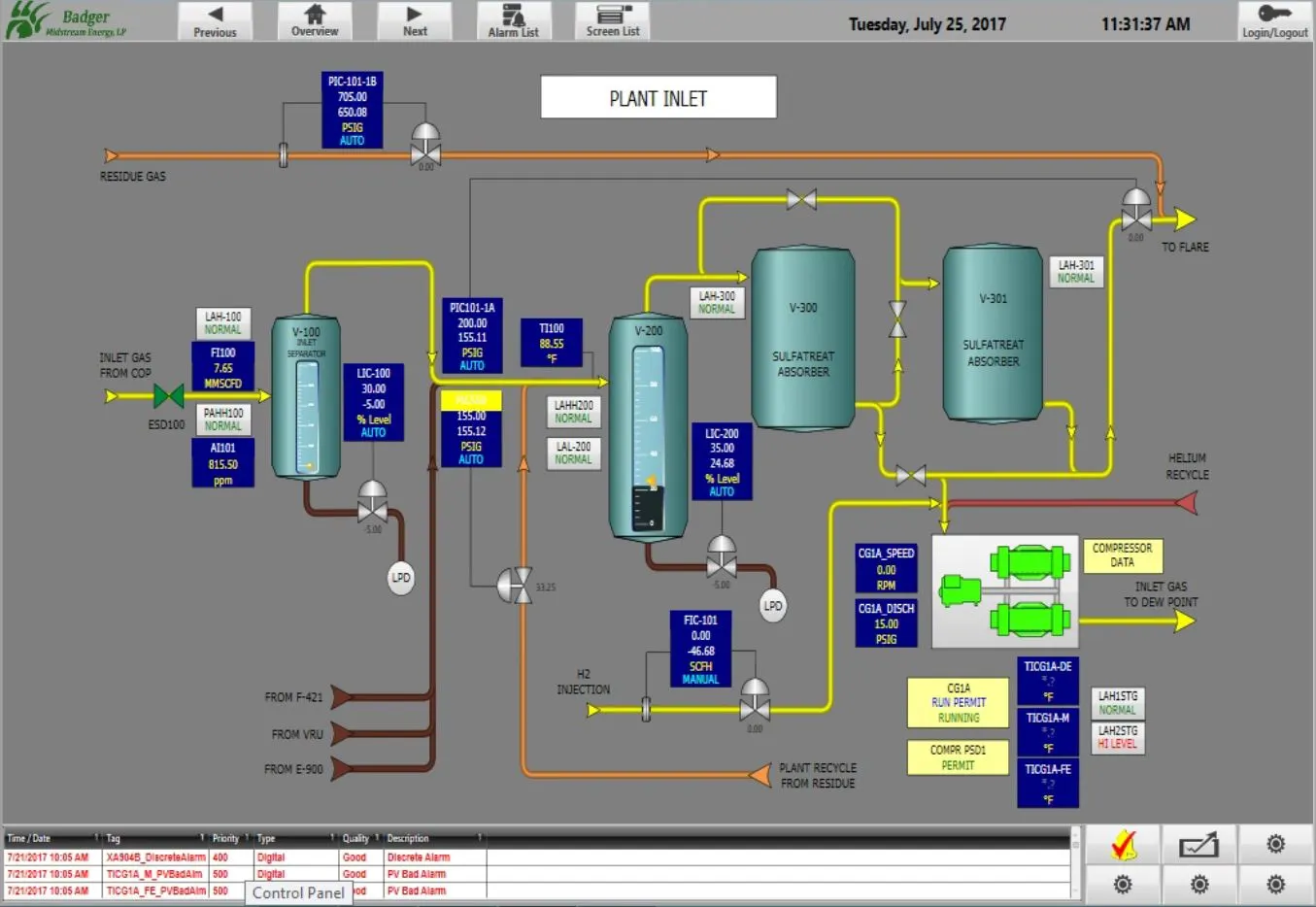

Plant Inlet Control Screen

Plant Inlet Control Screen

Badger Midstream knew almost immediately that their investment in GENESIS64, WebHMI, and MobileHMI automation software was the right decision. The company stated that the cost for the entire installation of our products was half of just the upgrade cost for only one of its pre-existing competitor products. Our software now helps to provide full plant control and metering of over 8,000 physical I/O points.

Associated process displays and faceplates were streamlined, providing enhanced process clarity and control to operators compared to the former system. In addition, multiple new features were gained, such as remote monitoring, mobile displays and notifications.

Plant Inlet Control Screen

Plant Inlet Control Screen

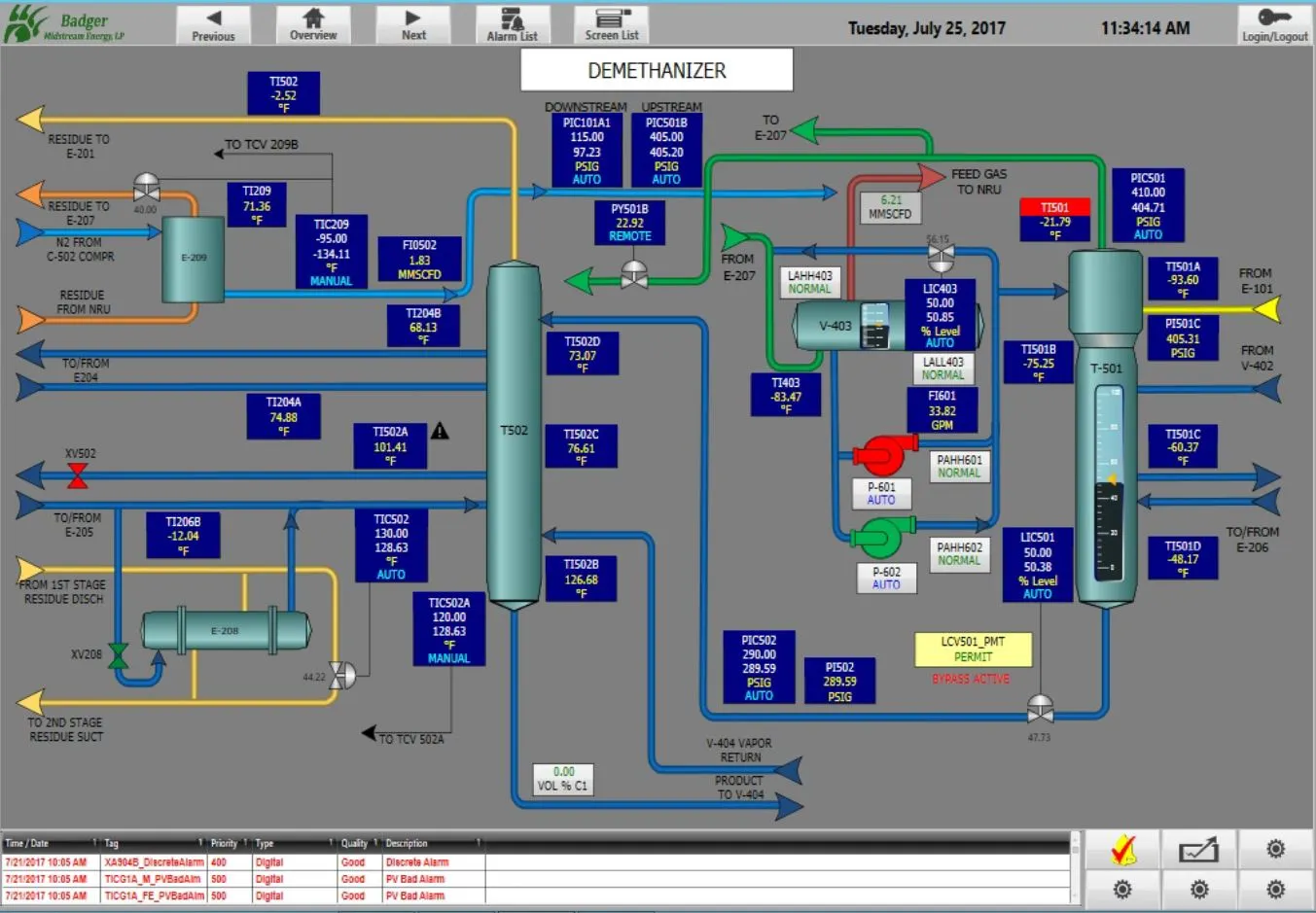

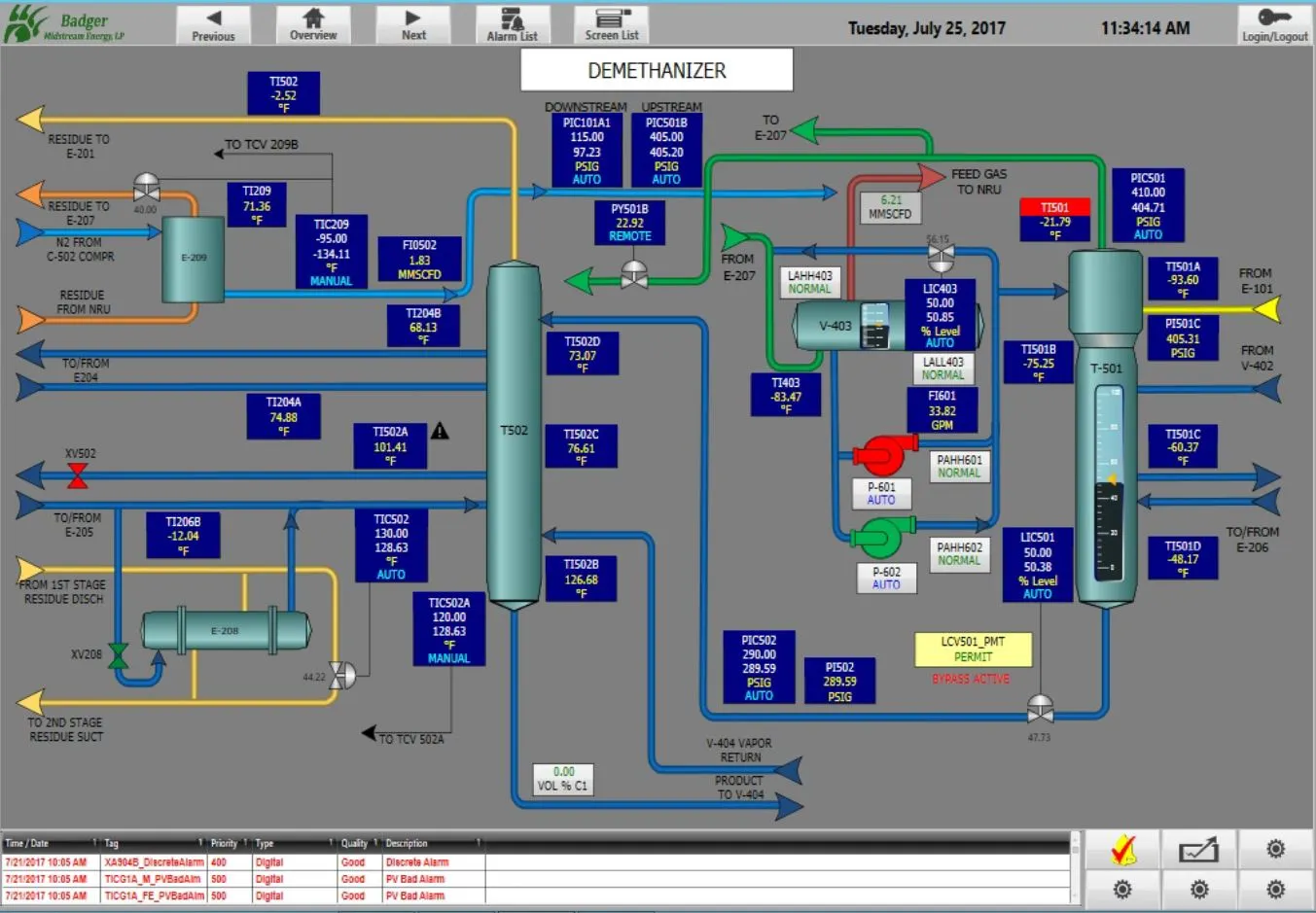

Demethanizer Monitoring and Controls

Demethanizer Monitoring and Controls

Badger Midstream plans to expand its installation of our automation software. The company would like to provide detailed dashboards to executives to show details including plant profitability, downtime and other associated metrics. For the company involved with cryogenic gas, the decision to remain with Mitsubishi Electric Iconics Digital Solutions was quite natural.

Demethanizer Monitoring and Controls

Demethanizer Monitoring and Controls